Multi-small-round-steel-bar punching mechanism for punch

A punching machine and round steel technology, which is applied in the field of multiple punching mechanisms for small round steel rods for punching machines, can solve the problems that the punching holes of the round guide sleeve are on the same axis, the processing is difficult, and the punching holes are discarded. Achieve the effect of improving device utilization rate and production cutting efficiency, improving cutting efficiency and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

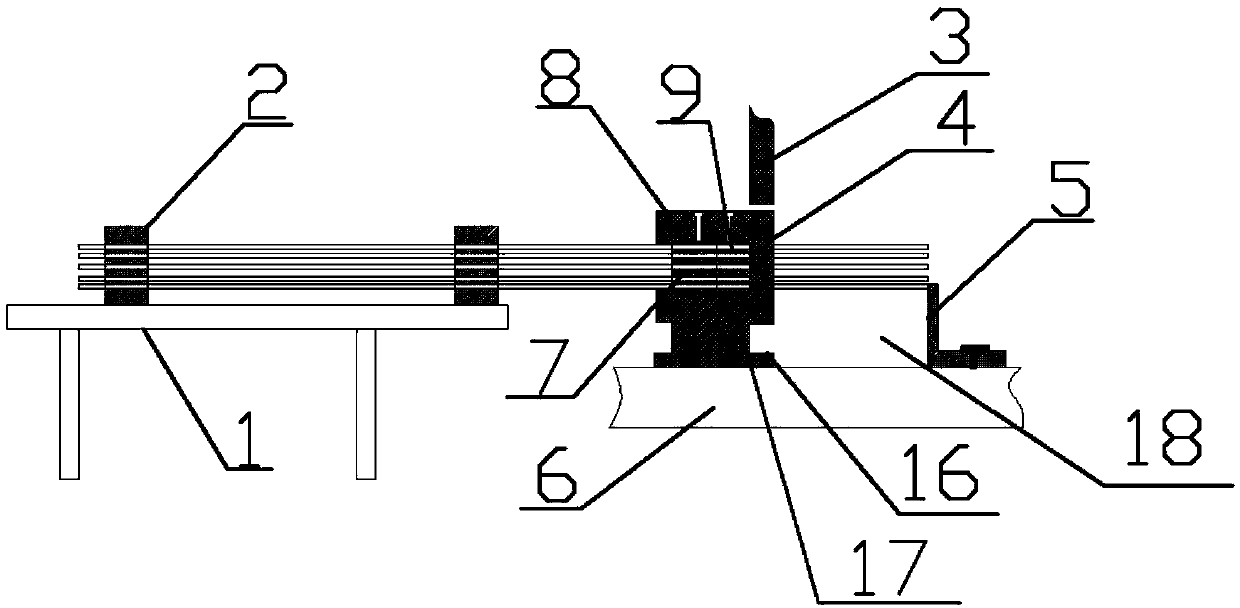

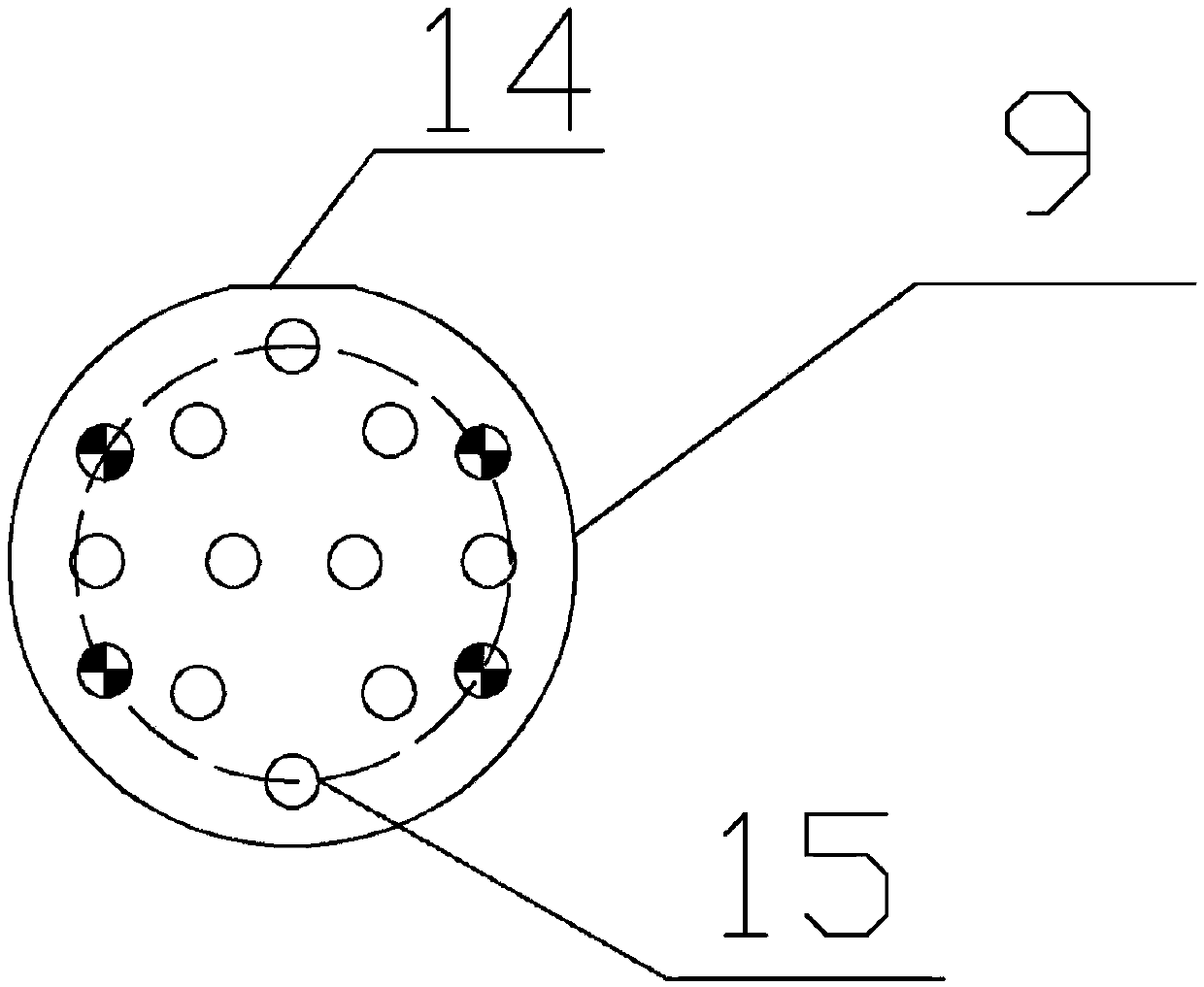

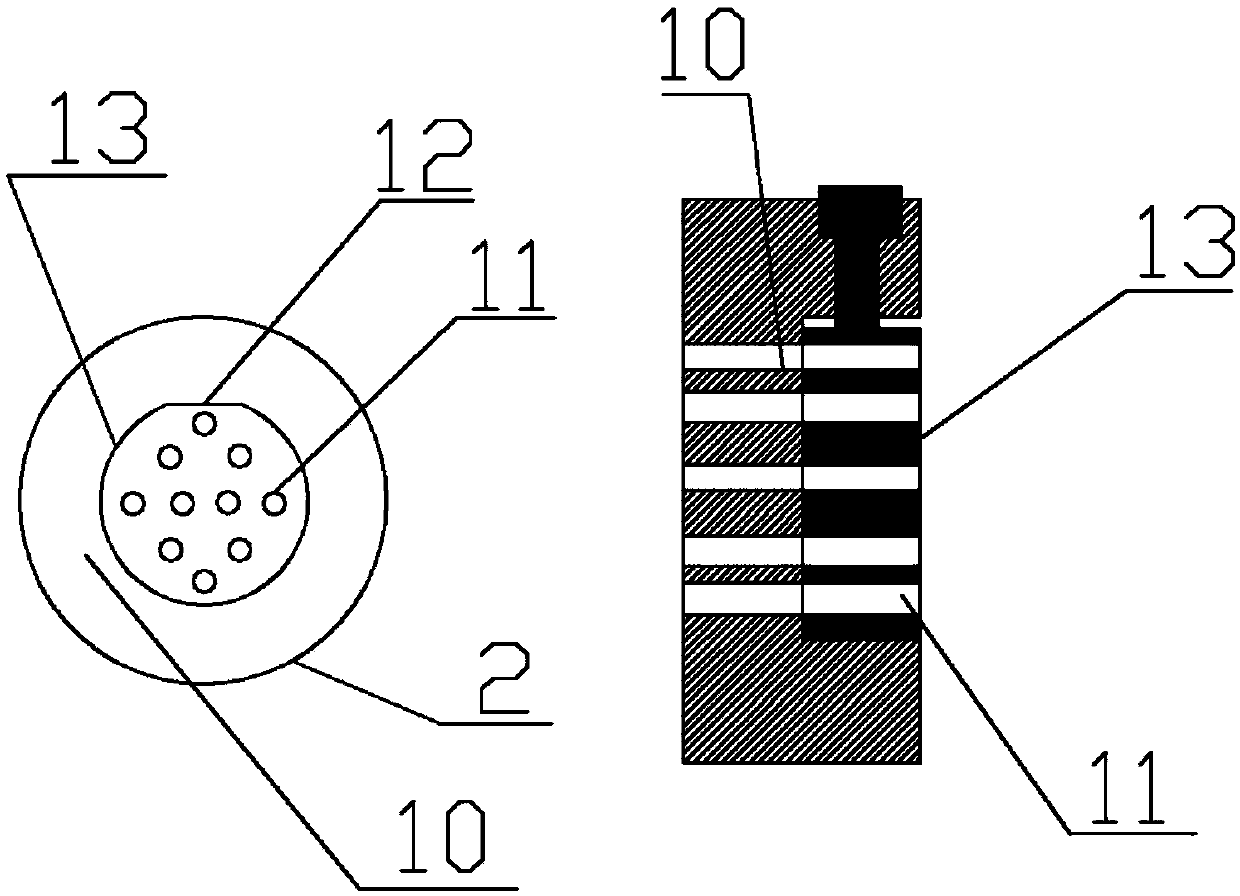

[0029] like figure 1 and 2As shown, the present embodiment provides a multi-branch punching mechanism for small round steel rods for a punching machine, including a lower die base 17, a loading rack 1 and a punch workbench 6, and the lower die base 17 is located at the punch workbench 6 The upper part of the upper part, the loading rack 1 is located on one side of the punch table 6, the lower mold base 17 is provided with a guide sleeve 7, and the guide sleeve 7 is correspondingly provided with a lower punching knife 9, the The lower punching knife 9 is provided with a punching hole 15, the diameter of the punching hole 15 is consistent with the inner diameter of the passage of the guide sleeve 7, and the punching hole 15 is not on the same vertical line as the adjacent punching hole 15. On, the top of the lower punching knife 9 is provided with a fixed surface 14, the lower punching knife 9 is fixed on the middle part of the outer side of the lower mold base 17, the front en...

Embodiment 2

[0031] like Figure 1-3 As shown, the present embodiment provides a multi-branch punching mechanism for small round steel rods for a punching machine, including a lower die base 17, a loading rack 1 and a punch workbench 6, and the lower die base 17 is located at the punch workbench 6 The upper part of the upper part, the loading rack 1 is located on one side of the punch table 6, the lower mold base 17 is provided with a guide sleeve 7, and the guide sleeve 7 is correspondingly provided with a lower punching knife 9, the The lower punching knife 9 is provided with a punching hole 15, the diameter of the punching hole 15 is consistent with the inner diameter of the passage of the guide sleeve 7, and the punching hole 15 is not on the same vertical line as the adjacent punching hole 15. On, the top of the lower punching knife 9 is provided with a fixed surface 14, the lower punching knife 9 is fixed on the middle part of the outer side of the lower mold base 17, the front end o...

Embodiment 3

[0034] like Figure 1-4 As shown, the present embodiment provides a multi-branch punching mechanism for small round steel rods for a punching machine, including a lower die base 17, a loading rack 1 and a punch workbench 6, and the lower die base 17 is located at the punch workbench 6 The upper part of the upper part, the loading rack 1 is located on one side of the punch table 6, the lower mold base 17 is provided with a guide sleeve 7, and the guide sleeve 7 is correspondingly provided with a lower punching knife 9, the The lower punching knife 9 is provided with a punching hole 15, the diameter of the punching hole 15 is consistent with the inner diameter of the passage of the guide sleeve 7, and the punching hole 15 is not on the same vertical line as the adjacent punching hole 15. On, the top of the lower punching knife 9 is provided with a fixed surface 14, the lower punching knife 9 is fixed on the middle part of the outer side of the lower mold base 17, the front end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com