A method of manufacturing reinforced concrete pillars for mine roadways

A production method and technology for concrete pillars, which are applied to tunnels, shaft linings, tunnel linings, etc., can solve the problems of difficult on-site pouring work, increased production costs, pillar loading and unloading, and difficulty in supporting underground transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Specific embodiments of the present invention will be further described in detail below.

[0053] Implementation of the above-mentioned manufacturing method provided by the present invention for mine roadway reinforced concrete pillars, the steps of the manufacturing method are as follows.

[0054] Step 1. According to the net section height X of the mine roadway design, and determine the assembly height Y for the reinforced concrete pillars of the mine roadway, so that the assembly height Y of the mine roadway reinforced concrete pillars is equal to the height X of the mine roadway design net section, that is, X =Y.

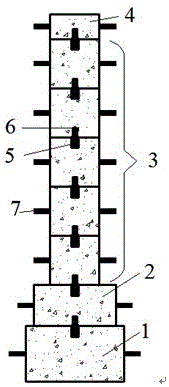

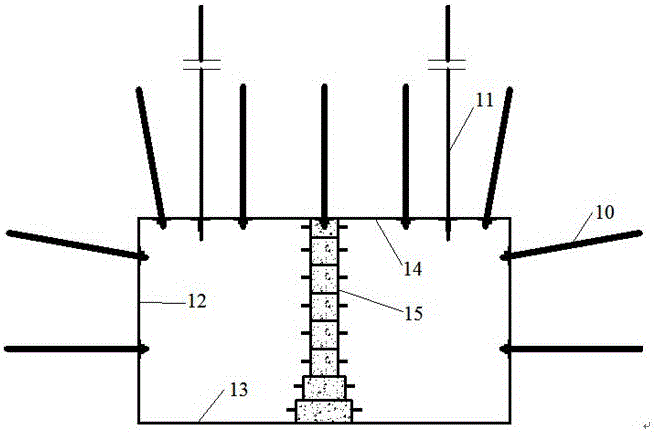

[0055] Step 2. The pillars described in the above step 1 are divided into parts, designed and processed into several sections of standard prefabricated parts. The standard prefabricated parts are composed of pillar base 1, pillar transition section 2, pillar main load-bearing section 3 and pillar main load-bearing connection top Section 4 constitutes.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com