Pre-blended mortar prepared from high-volume blaster furnace slag and preparation method thereof

A technology for ready-mixed mortar and furnace bottom slag, applied in the field of ready-mixed mortar, can solve the problems of difficulty, unstable product quality, influence on the overall strength of materials, etc., and achieve cost reduction, reduced use, workability and crack resistance. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of ready-mixed mortar prepared by using a large amount of furnace bottom slag. The mass parts of the ready-mixed mortar include: 100 parts of cement, 10 parts of thickened powder, 60 parts of fly ash, 648 parts of sand, 111 parts of furnace bottom slag, 0.111 parts of water reducing agent.

[0027] Among them, polycarboxylic acid is selected as the water reducing agent.

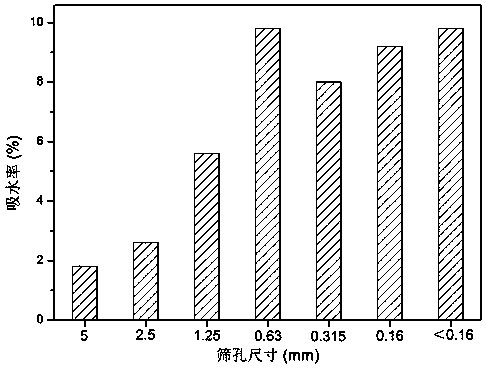

[0028] Among them, the particle size of the furnace bottom slag is less than 0.63mm.

[0029] Wherein, the bottom slag is pretreated bottom slag, and the pretreated bottom slag is obtained by soaking a surfactant and a coupling agent.

[0030] Wherein, the surfactant is selected from the fatty alcohol sulfate anion.

Embodiment 2

[0032] A kind of ready-mixed mortar prepared by using a large amount of furnace bottom slag. The mass parts of the ready-mixed mortar include: 105 parts of cement, 15 parts of thickened powder, 70 parts of fly ash, 486 parts of sand, 222 parts of furnace bottom slag, 0.222 parts of water reducing agent.

[0033] Among them, polycarboxylic acid is selected as the water reducing agent.

[0034] Among them, the particle size of the furnace bottom slag is less than 0.63mm.

[0035] Wherein, the bottom slag is pretreated bottom slag, and the pretreated bottom slag is obtained by soaking a surfactant and a coupling agent.

[0036] Wherein, the surfactant is selected from the fatty alcohol sulfate anion.

Embodiment 3

[0038] A kind of ready-mixed mortar prepared by using a large amount of furnace bottom slag. The mass parts of the ready-mixed mortar include: 110 parts of cement, 20 parts of thickened powder, 80 parts of fly ash, 324 parts of sand, 330 parts of furnace bottom slag, 0.111 parts of water reducing agent.

[0039] Among them, polycarboxylic acid is selected as the water reducing agent.

[0040] Among them, the particle size of the furnace bottom slag is less than 0.63mm.

[0041] Wherein, the furnace bottom slag is pretreated furnace bottom slag, and the pretreated furnace bottom slag is obtained by soaking a surfactant and a coupling agent.

[0042] Wherein, the surfactant is selected from the fatty alcohol sulfate anion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com