Skid-mounted gas fuel ignition device and ignition method thereof

A gas fuel and ignition device technology, applied in the gasification of granular/powder fuel, gas/liquid distribution and storage, pipeline system, etc., can solve the problems of valve failure, poor safety, frosting of pressure regulating valve, etc., and achieve mobile Flexible, easy-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

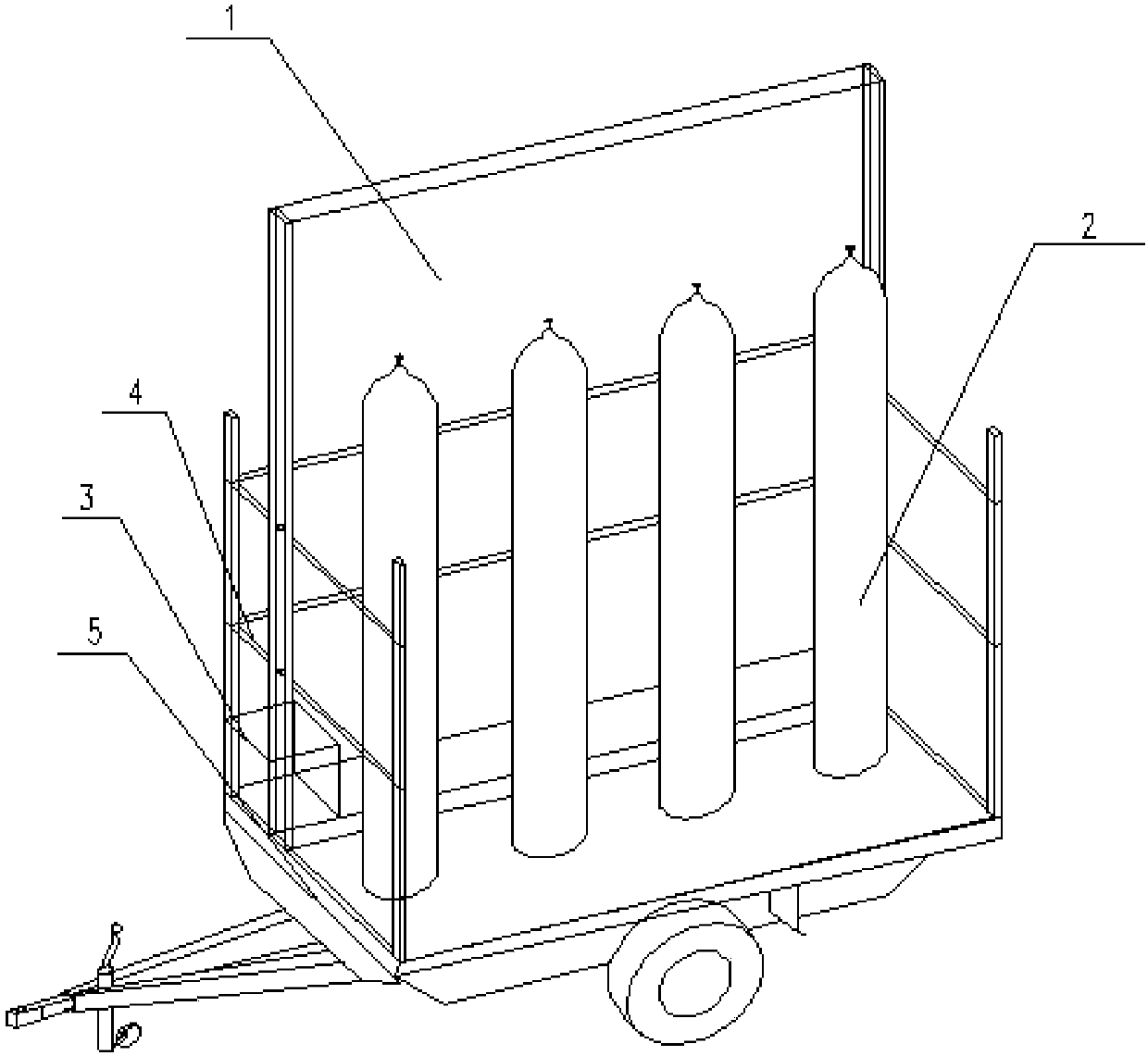

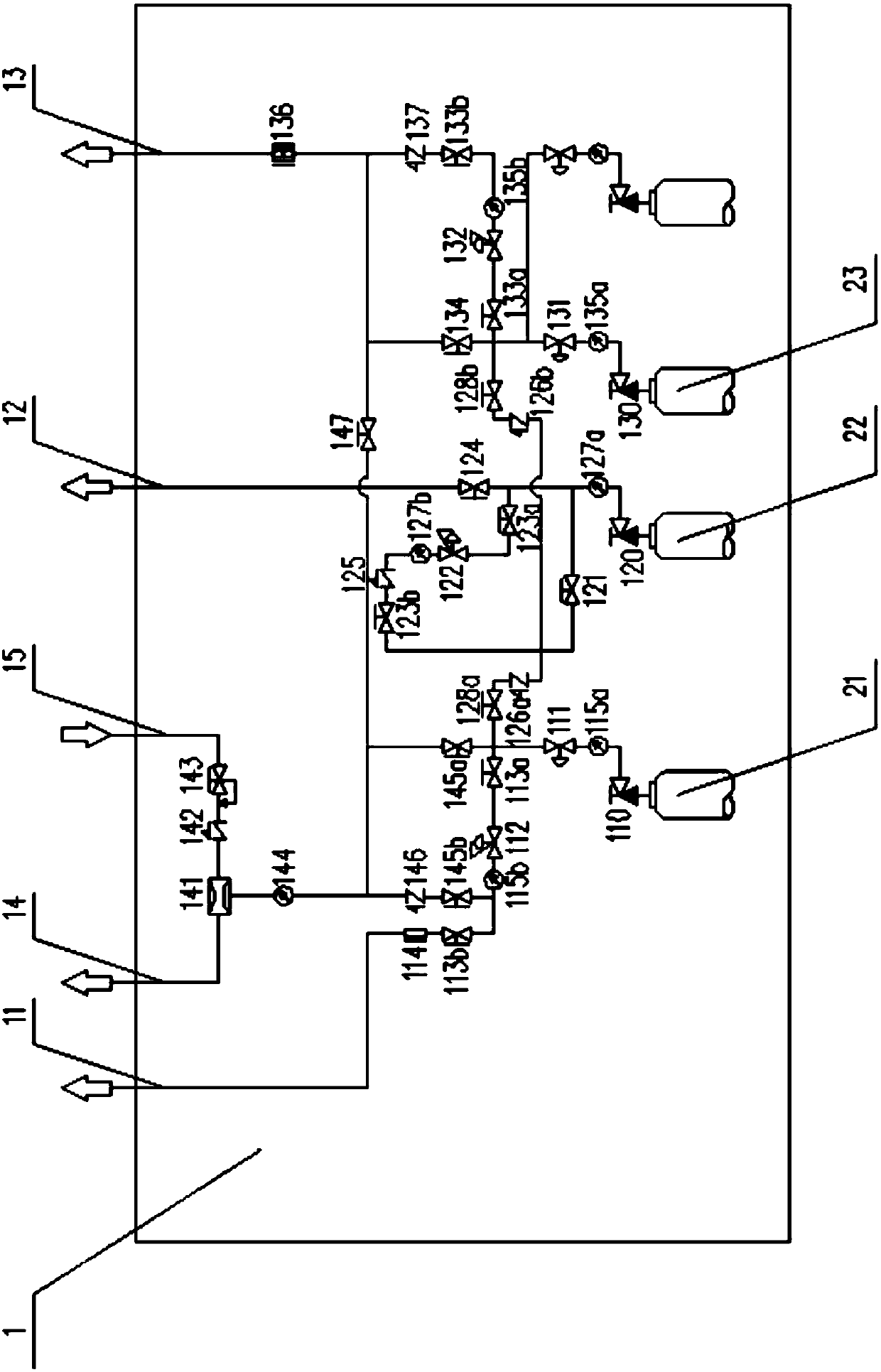

[0057] Such as figure 1 As shown, a skid-mounted gas fuel ignition device includes a valve instrument control panel 1, a gas storage, a fixed bracket 4, and a trailer 5. The gas storage and the valve instrument control panel 1 are both arranged on the trailer 5. The gas storage is used to provide the gas required for coal underground gasification ignition; A pipeline for transporting gaseous fuel, and the pipeline is equipped with valves and instruments for controlling the delivery of gaseous fuel.

[0058] In this embodiment, the gas storage is preferably a set of gas cylinders 2 . The trailer 5 includes a chassis, wheels, draw beams, etc., and the chassis of the trailer 5 carries a valve instrument control panel 1 and a gas cylinder group 2 to form an integrated skid-mounted body. The fixing bracket 4 is used to fix the valve instrument control panel 1 and the gas cylinder group 2 . The fixed bracket 4 is welded on the chassis of the trailer 5, including four square tube ...

Embodiment 2

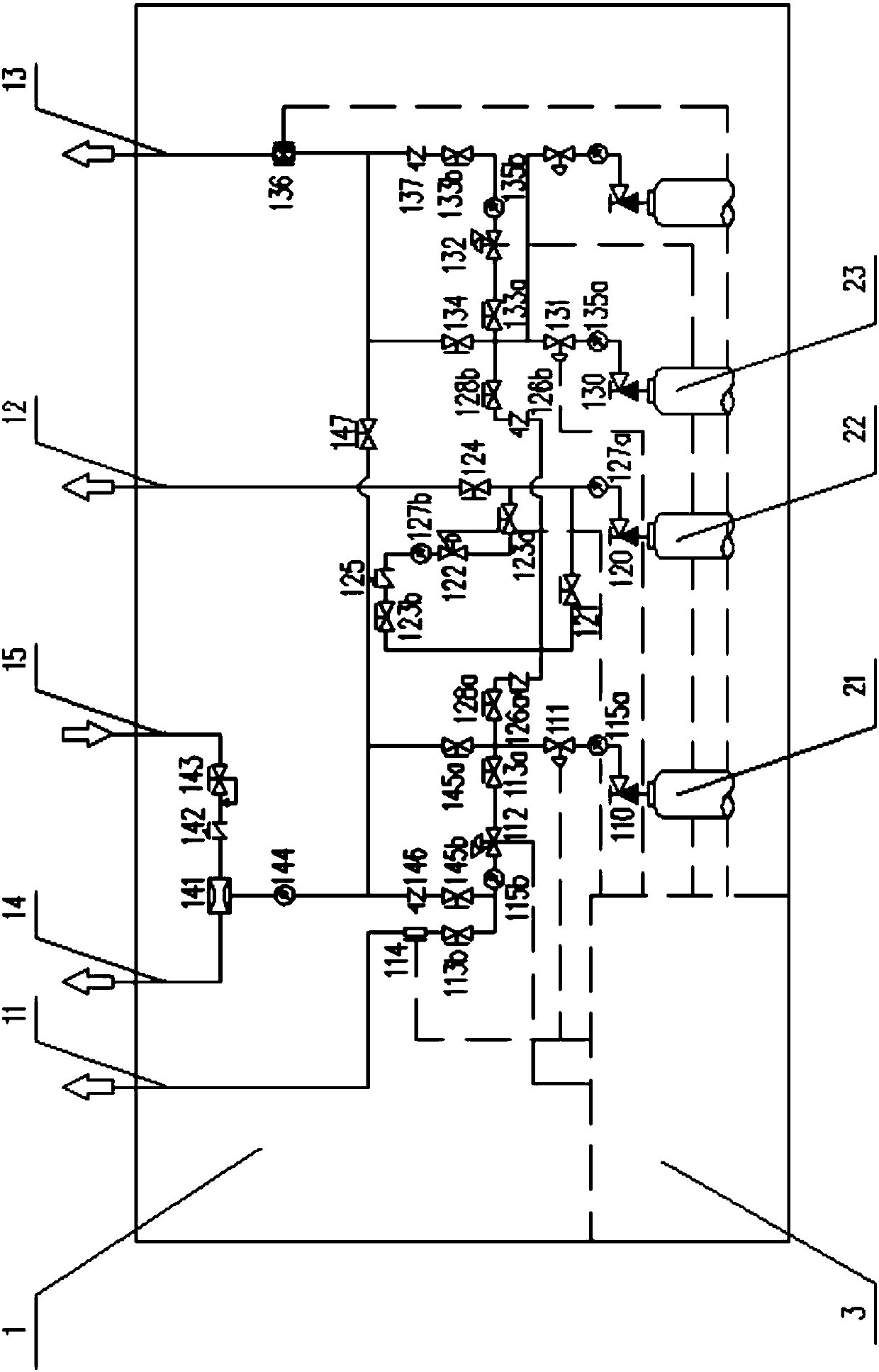

[0077] Parts that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to those in the first embodiment. For simplicity, only the differences between Embodiment 2 and Embodiment 1 are described.

[0078] On the basis of the structure of Embodiment 1, such as figure 1 and image 3 As shown, the skid-mounted gas fuel ignition device also includes an instrument and electrical control box 3, which is installed on the chassis of the trailer 5, arranged on the back of the valve instrument control panel 1, and can be fixed by the fixing bracket 4.

[0079] In order to realize the automatic control of the ignition device, the valve instrument control panel 1 is also provided with sensors (such as pressure sensors, temperature sensors, flow sensors, etc.) for collecting gas state signals and controllers and sensors for controlling the actions of each valve. It is connected to the signal input terminal of the controller, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com