Building structure of aluminum mold beam side plate above architectural door opening

A technology of aluminum formwork and aluminum formwork, which is applied in building construction, formwork/formwork components, and on-site preparation of building components, etc., can solve the problems of increased construction cost, large environmental impact of waste, and low overall construction efficiency. Achieve the effect of avoiding delays in the construction period, high construction efficiency, and preventing environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific embodiments. The purpose of the following words is to illustrate the present invention, rather than limit the protection scope of the present invention.

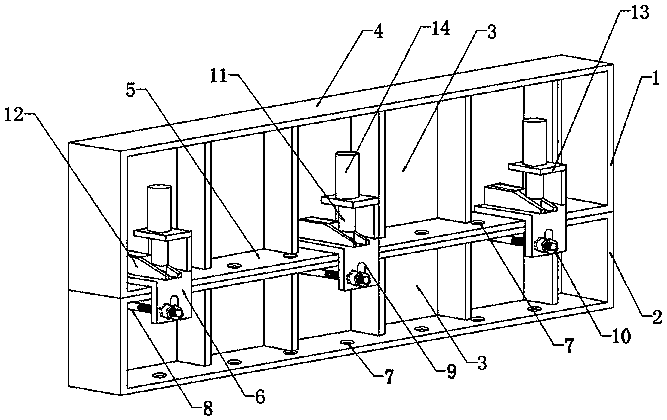

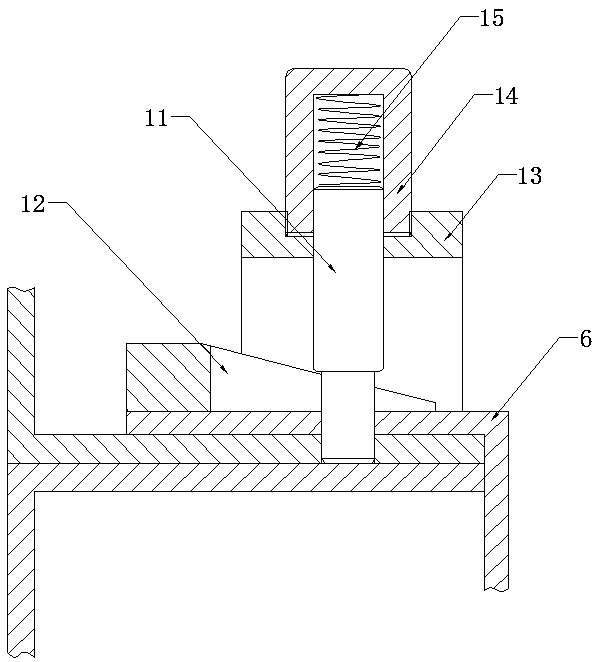

[0022] Such as figure 1 , figure 2 As shown, the present invention can be implemented in the following manner, a structure for erecting aluminum formwork beam side plates above a building doorway, comprising at least two aluminum formworks spliced up and down (this embodiment provides two conventional aluminum formworks, the heights of which are respectively 200mm and 150mm, that is, the upper 200mm aluminum formwork 1 and the lower 150mm aluminum formwork 2), each aluminum formwork is arranged in sequence along the same direction and is spliced up and down. The aluminum mold upper edge plate 4 and the aluminum mold lower edge plate 5 on the upper side and the lower side of the mold side beam plate 3, and the upper edge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com