Device for preparing metal semi-solid slurry

A semi-solid slurry and metal technology, which is applied in the field of metal semi-solid processing equipment, can solve the problems of uneven processing quality, difficult control of the production process, and complex forming, so as to improve the effect of grain refinement, realize process automation, and guarantee The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described through the following embodiments in conjunction with the accompanying drawings.

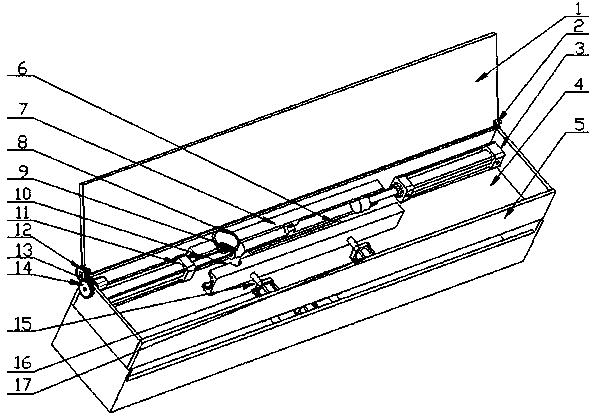

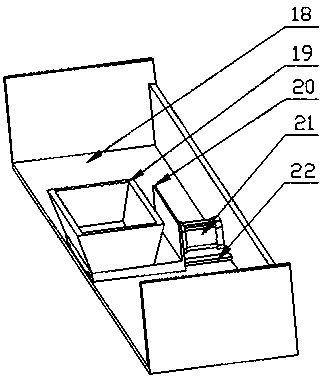

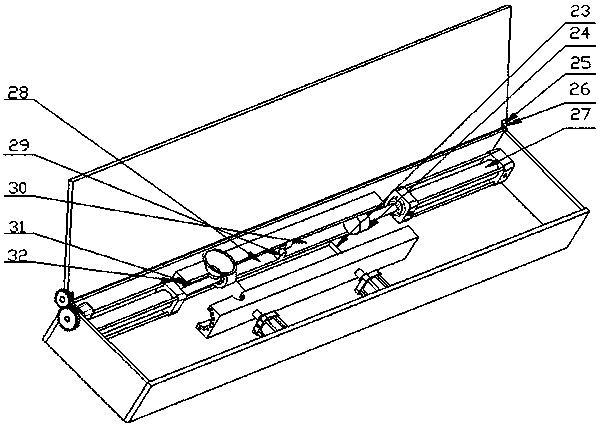

[0026] like figure 1 and figure 2 As shown, the metal semi-solid slurry preparation device provided by the present invention includes: a safety baffle 1, a rotating assembly 2, a processing assembly 3, a mounting seat 4, a side plate 5, a fixed mold 7, a movable mold 10, and a mold locking device 15. The receiving assembly 23. The whole movement process of the device is controlled by electric control elements.

[0027] The processing assembly 3 is mainly composed of a hydraulic cylinder A11, a hydraulic cylinder B27, a piston A9, a piston B24, a fixed die 7 and a movable die 10. The fixed mold 7 and the movable mold 10 are equipped with installation holes for heating and temperature measuring elements, and the outer layer is wrapped with thermal insulation materials. The heating device heats the fixed mold 7 and the movable mold 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com