Novel wheel

A wheel, a new type of technology, applied in the direction of wheels, wheel manufacturing, wheels made of non-metallic materials, etc., can solve the problems of inconvenient storage and handling of baby carriages, reduce the service life of tires, and high production costs, etc., to achieve moderate hardness and enhanced Effects of improving mechanical strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

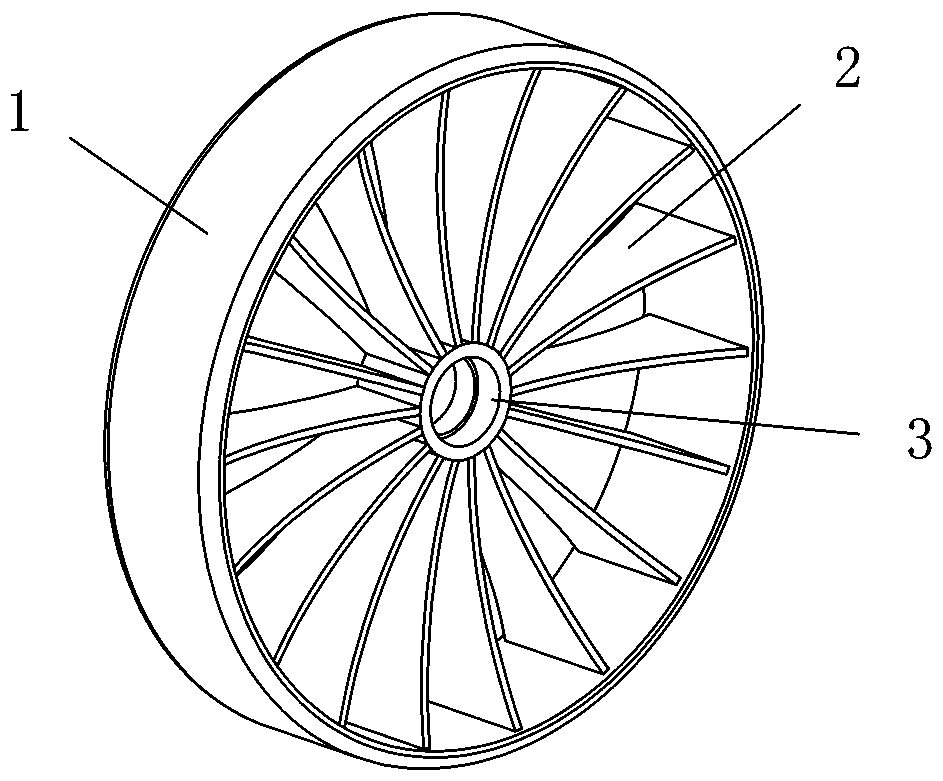

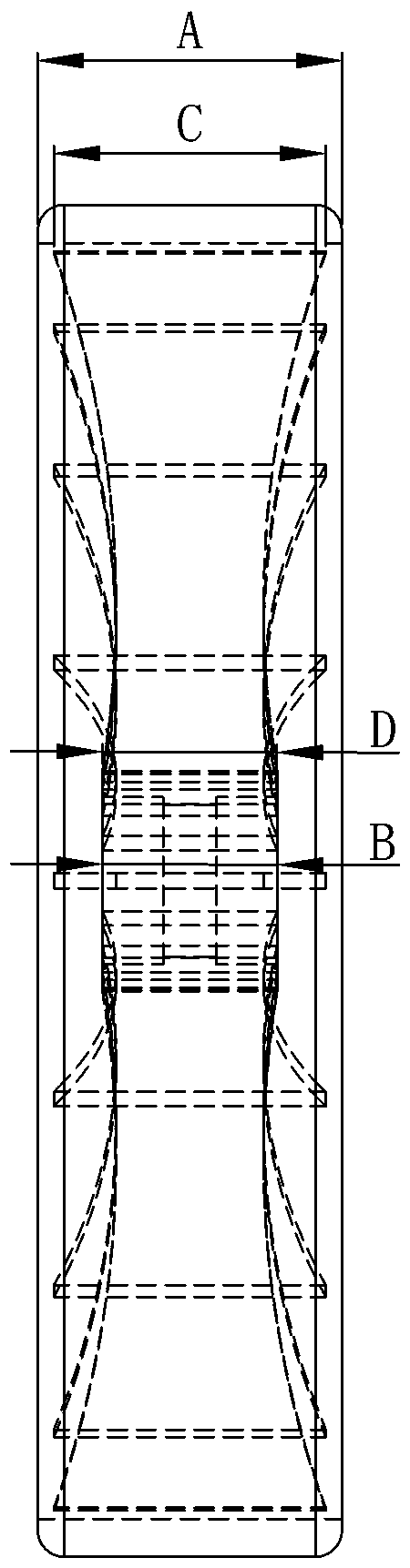

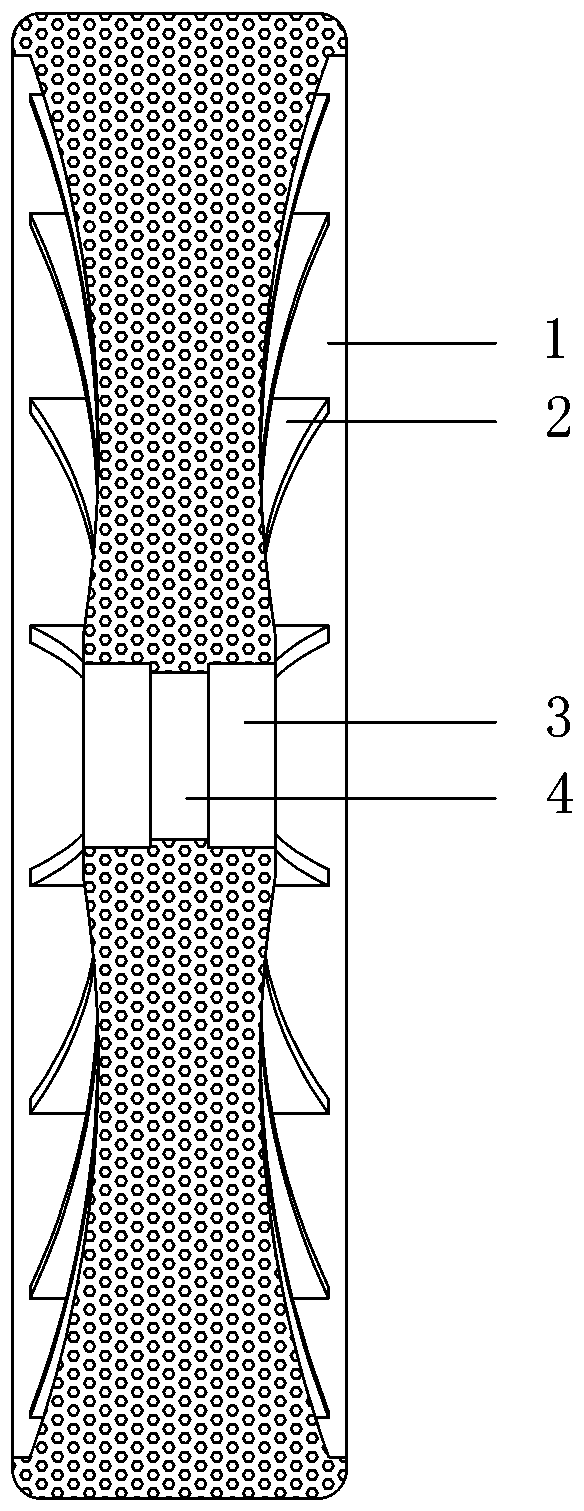

[0022] refer to Figure 1 to Figure 3 , a new type of wheel, comprising an integrally formed wheel body, the wheel body is sequentially provided with a tire part 1, a spoke part 2 and a wheel shaft part 3 from the outside to the inside, the outer side of the spoke part 2 and the tire part 1 The inner side is connected, and the inner side is connected with the outer side of the axle part 3 , and the spoke part 2 supports the tire part 1 . In the prior art, there are various methods for the integrated molding of the wheel body. For example, 3D printing technology is used for integral molding, and the embryos of the tire part 1, the spoke part 2 and the wheel axle part 3 are made of different molds and different formulations of raw materials. They are produced separately, and then these embryos with different characteristics are nested together and foamed in a foaming mold, so that the tire part 1, the spoke part 2 and the wheel axle part 3 are integrally formed. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com