Capsule used on capsule extraction machine

An extraction machine and capsule technology, which is applied in the field of capsule extraction machines, can solve the problems of capsule extraction machine residue, unfavorable capsule extraction machine hygiene, complex capsule extraction machine structure, etc., and achieve the effect of improving drinking taste, simplifying structure, and ensuring freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

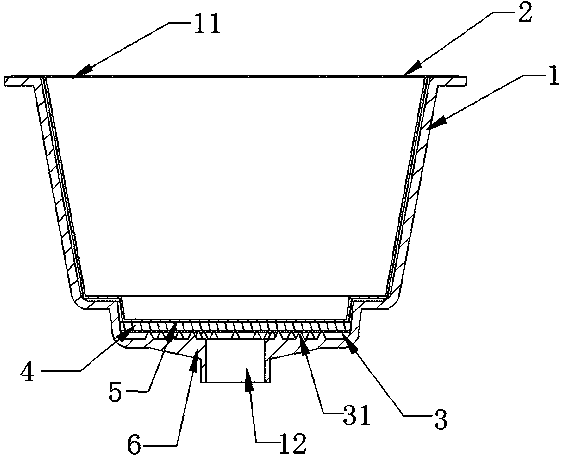

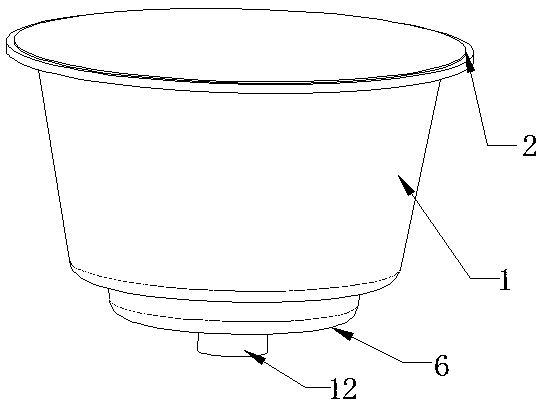

[0023] A schematic diagram of a capsule used in a capsule extractor in this embodiment is as Figure 1 to Figure 2 As shown, the capsule body 1 is included, the top and the bottom of the capsule body 1 are respectively provided with an opening 11 and a liquid collecting hole 12, the opening 11 is provided with a sealing film 2 for sealing the opening 11, and the inside of the capsule body 1 is provided with a The sealing film 4 between the substance to be brewed and the liquid collecting hole 12; a thorn disc 3 is arranged between the sealing film 4 and the liquid collecting hole 12, and the thorn disc 3 communicates with the liquid collecting hole 12; when the pressure on the sealing film 4 When the first threshold is reached, the piercing disk 3 pierces the sealing film 4 .

[0024] In this embodiment, the substance to be brewed can be powder, dry body or concentrated liquid; the liquid collecting hole 12 extends out of the bottom of the capsule body 1, so that when the caps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com