A copper octanoate preparing method and a copper octanoate product

A technology of copper octoate and octanoic acid is applied in the preparation of carboxylate, carboxylate, preparation of organic compounds, etc., can solve the problems of complicated preparation method of copper octoate, and achieves the effects of good performance, simple operation and strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

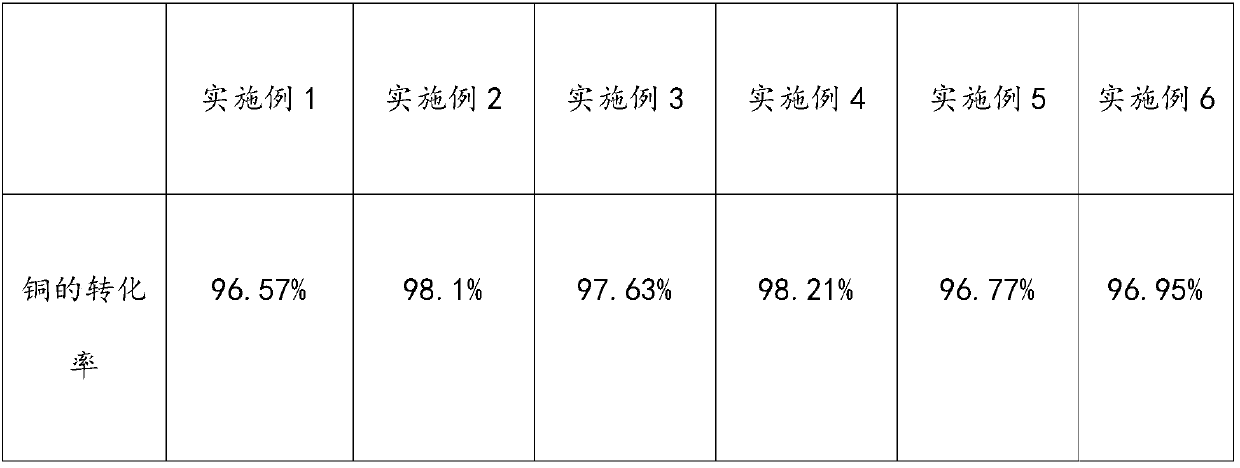

Examples

Embodiment 1

[0064] The present embodiment provides a kind of preparation method of copper octanoate, comprises the following steps:

[0065] 1) Take 20ml octanoic acid and place it in a 250mL three-necked flask, add water to twice the volume of the acid, heat and stir at 30°C for 30min in a water bath to prepare the first solution.

[0066] 2) Prepare a sodium hydroxide solution, add the sodium hydroxide solution to the first solution, raise the temperature to 55° C., stir and react for 30 minutes to obtain the second solution.

[0067] 3) Distill 90% of the water in the second solution.

[0068] 4) Then add 50ml of 120# organic oil, shake well, slowly add copper sulfate feed solution dropwise, and react for 2 hours.

[0069] 5) Transfer the liquid to a 250mL separatory funnel, and let stand to separate layers. Then carry out the liquid separation operation, take the upper layer solution, wash 3 times with 95 ℃ hot water, the volume of hot water is 2 times of the organic phase volume. ...

Embodiment 2

[0072] The present embodiment provides a kind of preparation method of copper octanoate, comprises the following steps:

[0073] 1) Take 20ml octanoic acid and put it in a 250mL three-neck flask, add water to 1.5 times the volume of the acid, heat and stir at 30°C for 30min in a water bath to prepare the first solution.

[0074] 2) Prepare a sodium hydroxide solution, add the sodium hydroxide solution to the first solution, raise the temperature to 50° C., stir and react for 30 minutes to obtain the second solution.

[0075] 3) Distill 50% of the water in the second solution.

[0076] 4) Then add 50ml of 120# organic oil, shake well, slowly add copper sulfate feed solution dropwise, and react for 6h.

[0077] 5) Transfer the liquid to a 250mL separatory funnel, and let stand to separate layers. Then carry out the liquid separation operation, take the upper layer solution, wash 3 times with 40 ℃ hot water, the volume of the hot water is 0.5 times of the volume of the organic ...

Embodiment 3

[0080] The present embodiment provides a kind of preparation method of copper octanoate, comprises the following steps:

[0081] 1) Take 20ml octanoic acid and place it in a 250mL three-neck flask, add water to 1.6 times the volume of the acid, heat and stir at 30°C for 30min in a water bath to prepare the first solution.

[0082] 2) Prepare a sodium hydroxide solution, add the sodium hydroxide solution to the first solution, raise the temperature to 60° C., stir and react for 30 minutes to obtain the second solution.

[0083] 3) Distill 60% of the water in the second solution.

[0084] 4) Then add 50ml of 120# organic oil, shake well, slowly add copper sulfate feed solution dropwise, and react for 3.5h.

[0085] 5) Transfer the liquid to a 250mL separatory funnel, and let stand to separate layers. Then carry out the liquid separation operation, take the upper layer solution, wash 3 times with 60 ℃ hot water, the volume of the hot water is 1 times of the volume of the organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com