Vibration prevention device and die-casting machine servo energy-saving system

A technology of anti-vibration device and pressure plate, which is applied in the direction of shock absorber, mechanical equipment, spring/shock absorber, etc., can solve the problems of system wear, strong vibration of servo system, loud noise, etc., and achieve the elimination of potential hazards, wide applicability, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

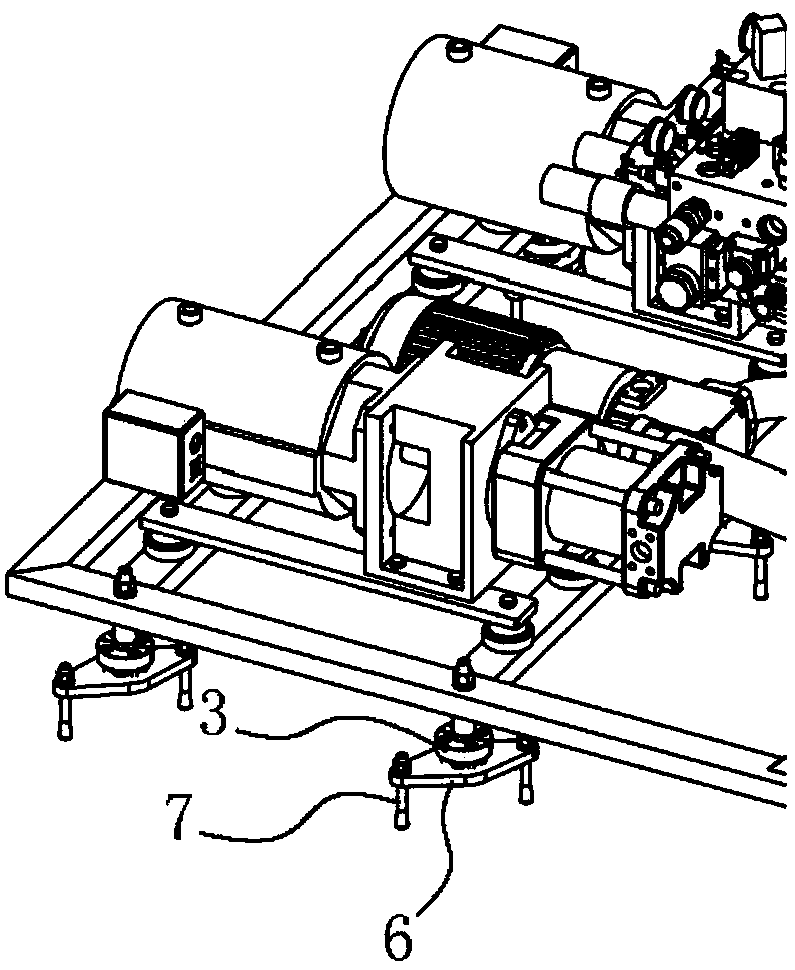

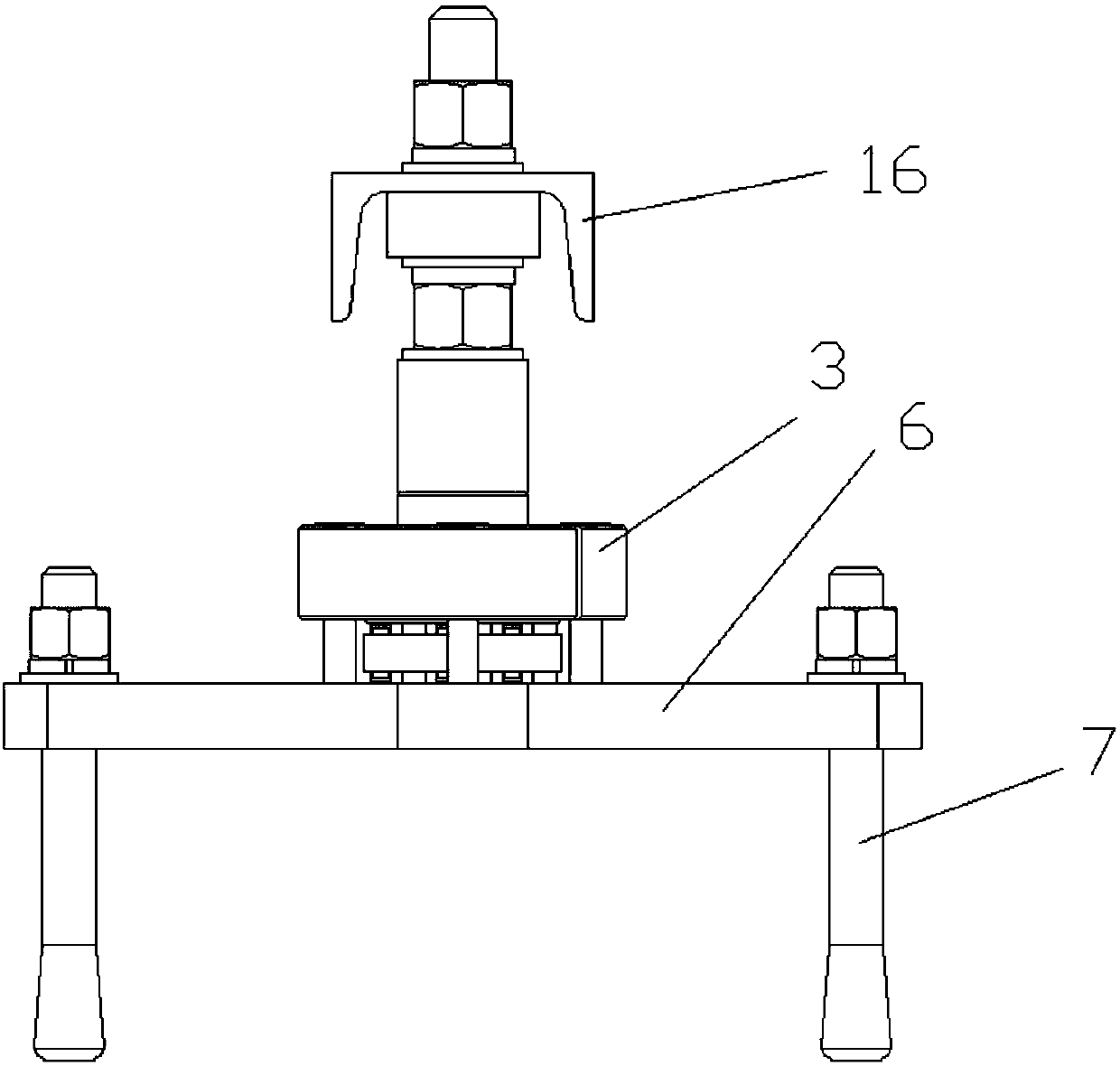

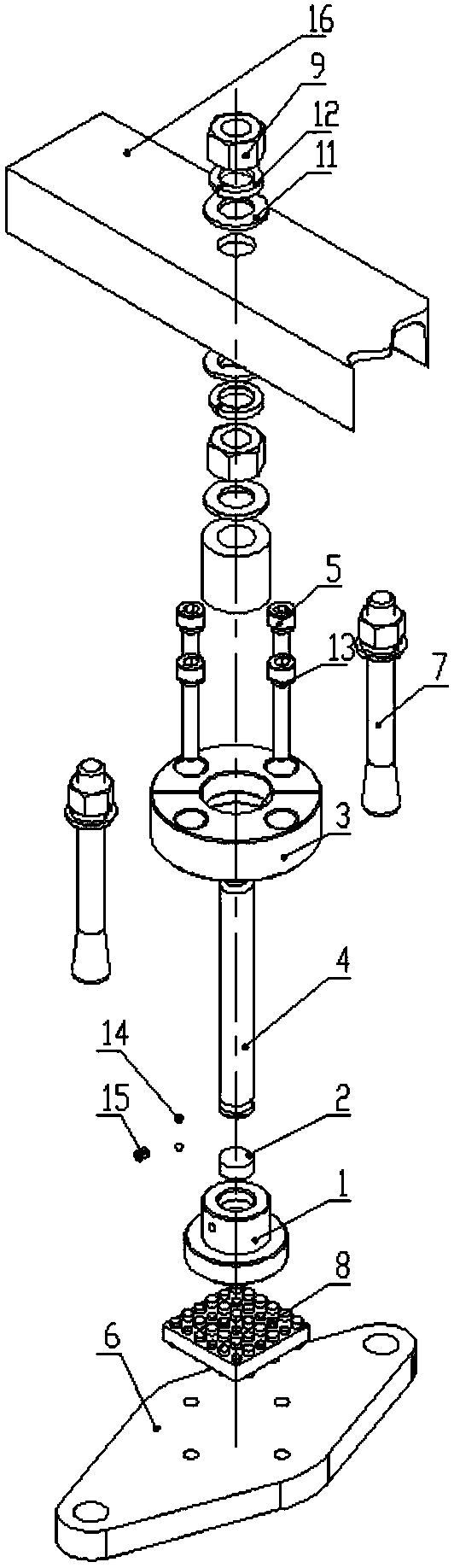

[0021] Example Figure 1-4 As shown, an anti-vibration device applied to the servo energy-saving system of a die-casting machine includes a base plate 6 for connecting the feet 7, a rubber pad 8 is provided on the upper end of the base plate 6, and a connecting plate is provided above the rubber pad 8 1. The connecting plate 1 and the bottom plate 6 are pressed together, and the upper end of the connecting plate 1 is connected with an adjustment rod 4 .

[0022] A rubber pad 8 is added between the connection plate 1 and the bottom plate 6 to effectively eliminate the vibration from the adjustment rod and the connection plate, and reduce the vibration impact of the parts above the adjustment rod.

[0023] The upper and lower end surfaces of the rubber pad 8 are respectively provided with several protrusions to further reduce the vibration impact.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap