Automobile self-resetting vibration absorber

A self-reset, shock absorber technology, applied in shock absorbers, gas-liquid shock absorbers, shock absorbers, etc., can solve the problems of time-consuming and labor-intensive, product failure, manual rotation reset, etc., to achieve good controllability and Driving stability, reducing collision noise, good reset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

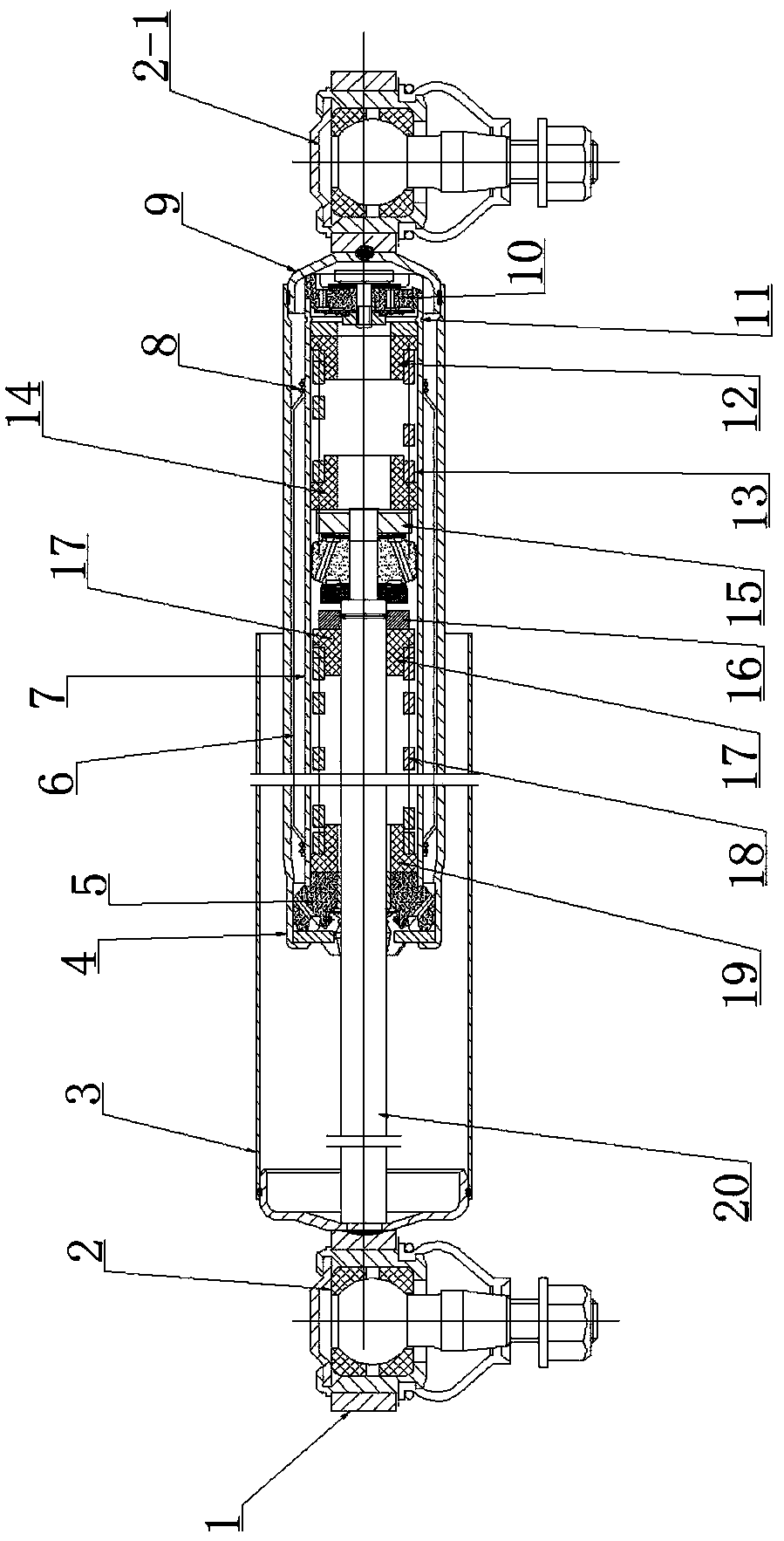

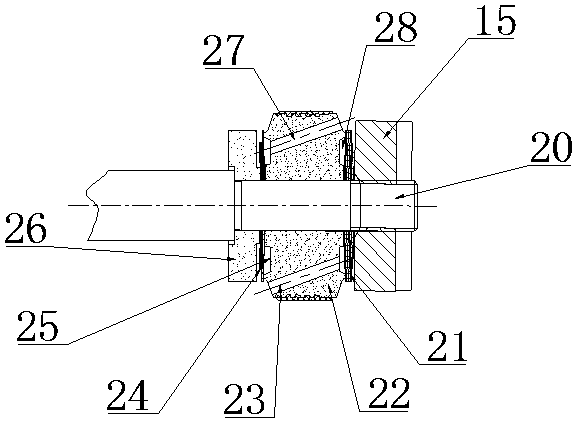

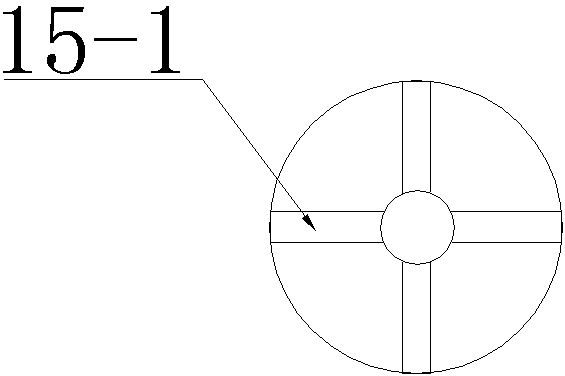

[0020] Example: such as Figure 1-3 As shown, the automobile self-resetting shock absorber includes a working cylinder assembly and a piston rod 20 assembly. The working cylinder assembly includes an oil storage cylinder assembly 4 and an inner working cylinder 7. The inside of the working cylinder assembly is filled with oil, and the oil storage cylinder assembly The outer left end of Cheng 4 is provided with a dust cover 3, the left end of the dust cover 3 is fixed on the right end of the left ball head bushing 2, and an air bag 6 is arranged between the oil storage cylinder assembly 4 and the inner working cylinder 7, and the air bag 6 is arranged along the axial direction. Sleeved on the outer peripheral surface of the inner working cylinder 7, the axial ends of the airbag 6 are sealed and bonded to the outer peripheral surface of the inner working cylinder 7, and an air cavity is formed between the middle part and the outer peripheral surface of the inner working cylinder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com