Crane cable for heat treatment workshop

A cable and crane technology, which is applied in the field of machinery, can solve problems such as scalding, workers need to stand far away and lift very high, and inconvenient operation, so as to achieve the effect of improving the convenience of operation and improving the versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

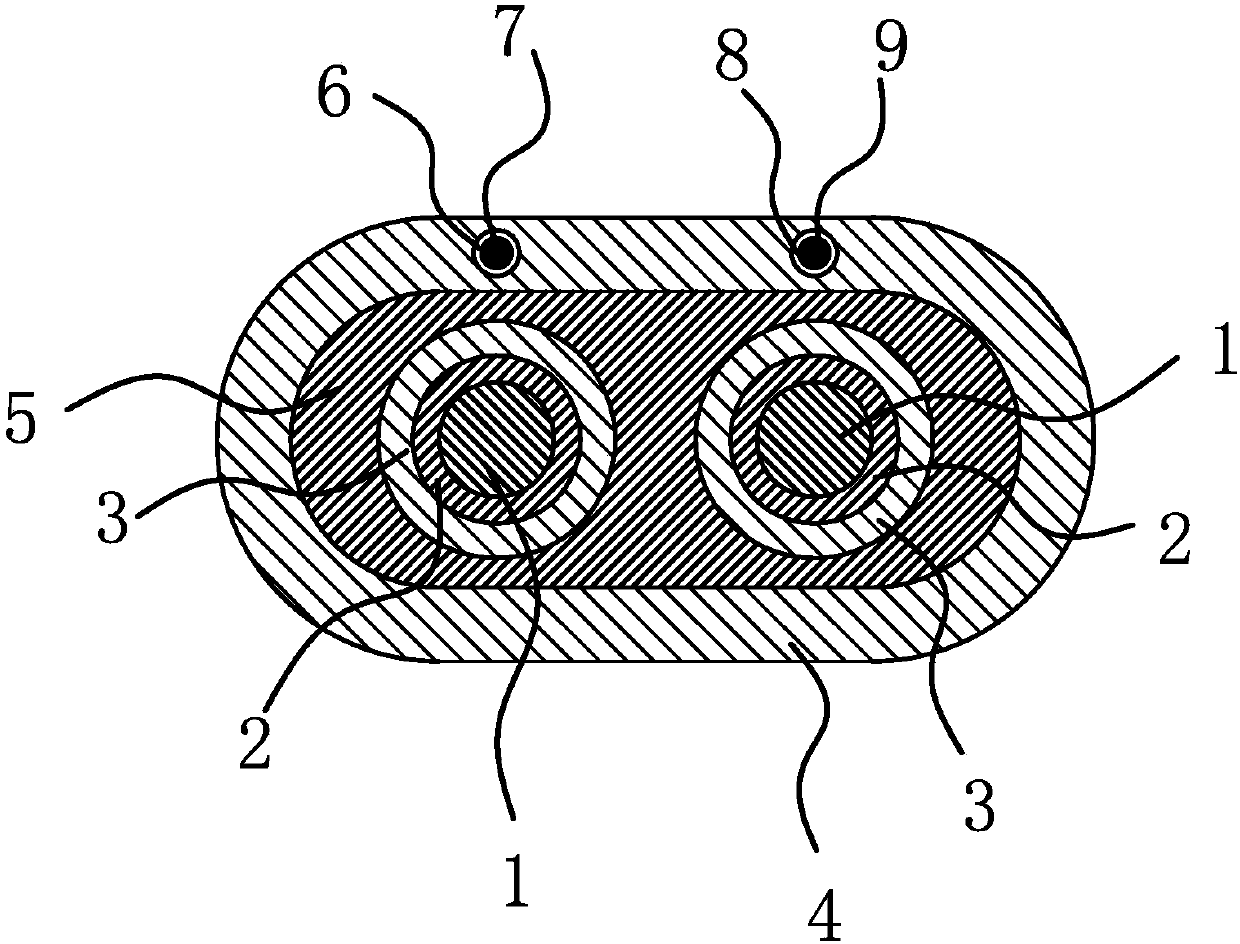

[0024] like figure 1 As shown, the suspension cable of this bank includes two conductors 1, the conductor 1 is covered with an insulating layer 2, the insulating layer 2 is covered with a protective layer 3, the protective layer 3 is covered with a sheath 4, and the gap between the sheath 4 and the protective layer 3 Fire retardant particles 5 are filled between them. In this embodiment, the insulating layer 2 is made of natural rubber mixture; the protective layer 3 is made of nylon; the sheath 4 is made of neoprene. The sheath 4 is provided with a channel-6 along its length direction, and a memory alloy wire-7 is arranged in the channel-6. The memory alloy wire-7 is linear at room temperature. When the memory alloy wire-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com