Mechanical deicing and thermal deicing-integrated deicing robot control system

A control system and robot technology, applied in the installation of cables, electrical components, overhead installation, etc., can solve the problems of poor deicing effect, limited effect, complicated operation, etc., and achieve good deicing effect and high deicing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

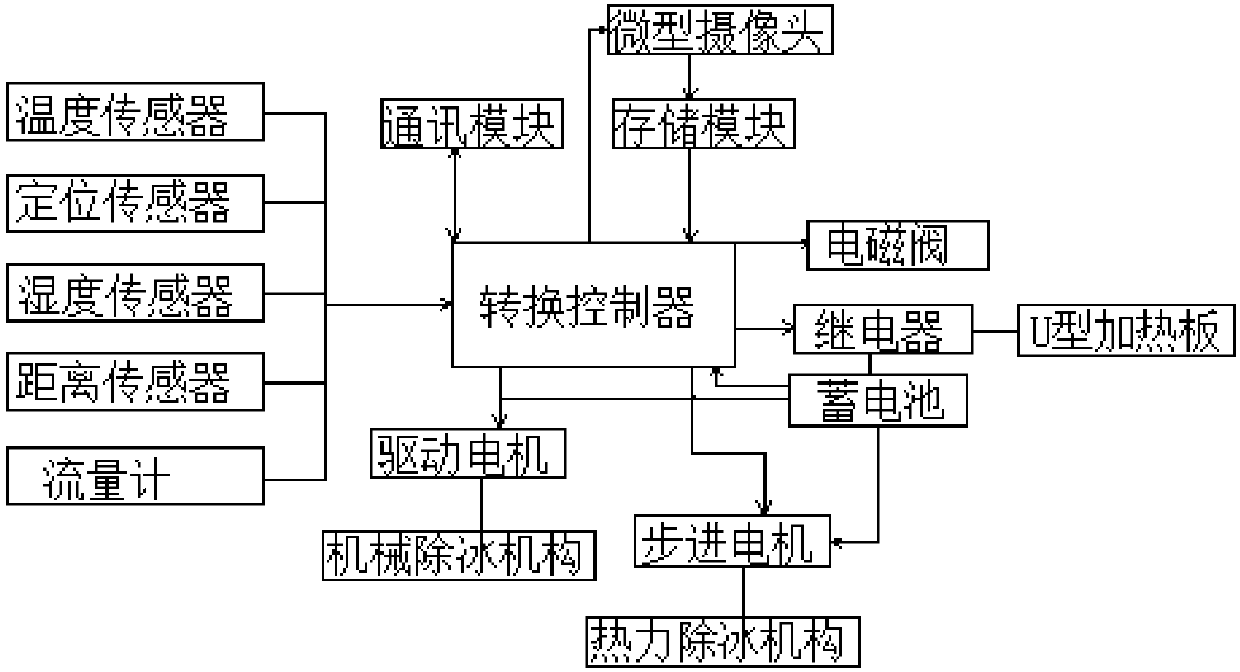

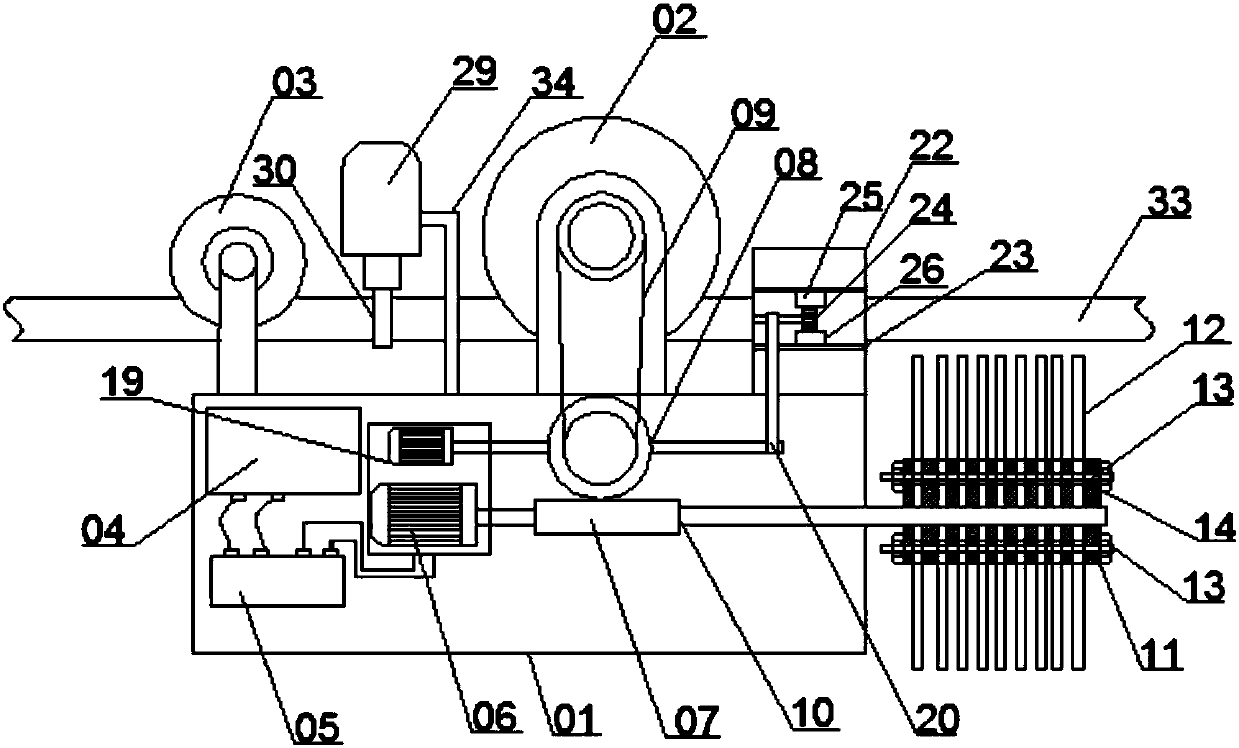

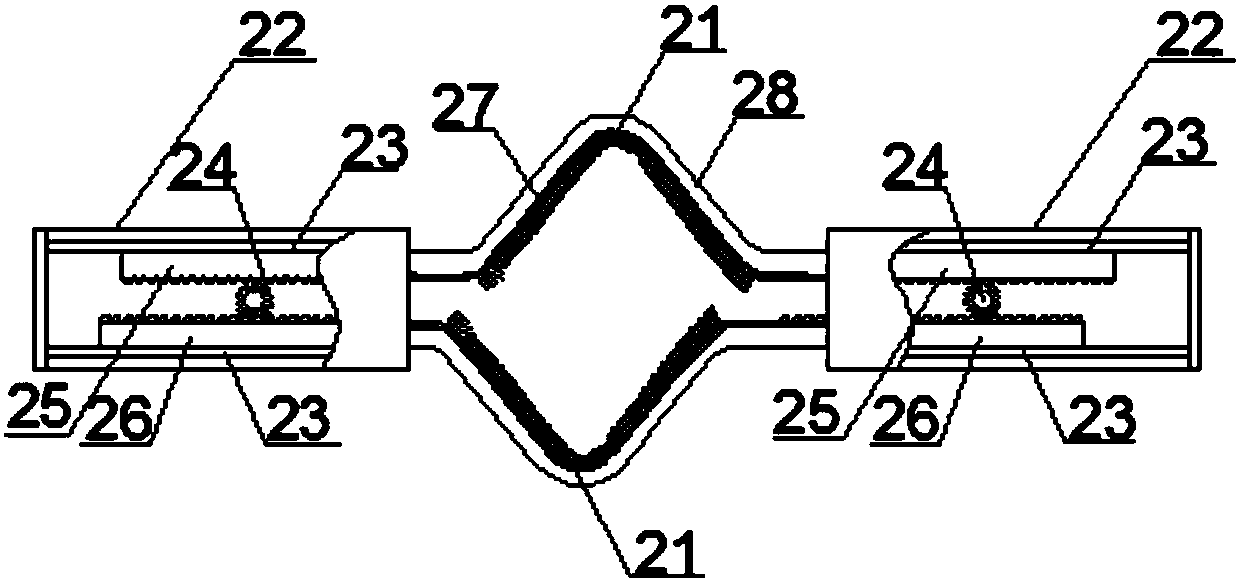

[0033] Please refer to figure 1 As shown, this embodiment provides a deicing robot control system integrating mechanical deicing and thermal deicing, including a communication module, a conversion controller 05 installed on the deicing robot, a battery 04, and a mechanism for driving the mechanical deicing The driving motor 06 for breaking ice and the stepping motor 19 that drives the thermal deicing mechanism for deicing, and the storage battery 04 are electrically connected to the conversion controller 05, the driving motor 06 and the stepping motor 19 respectively; Remotely control the intelligent deicing of the overhead deicing robot; the mechanical deicing mechanism is driven by the conversion controller 05 to control the rotation of the drive motor 06 to achieve mechanical ice breaking; the thermal deicing mechanism is equipped with a U-shaped heating plate 21 and a U-shaped heating plate 21 The electrically connected relay and the temperature sensor installed on the U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com