Suspension type swirling flow demisting system

A suspended and swirling technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high power consumption, easy to block the screen, and the reliability of the screen demister needs to be verified, etc., to achieve Effects of increasing reliability, avoiding corrosion or clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

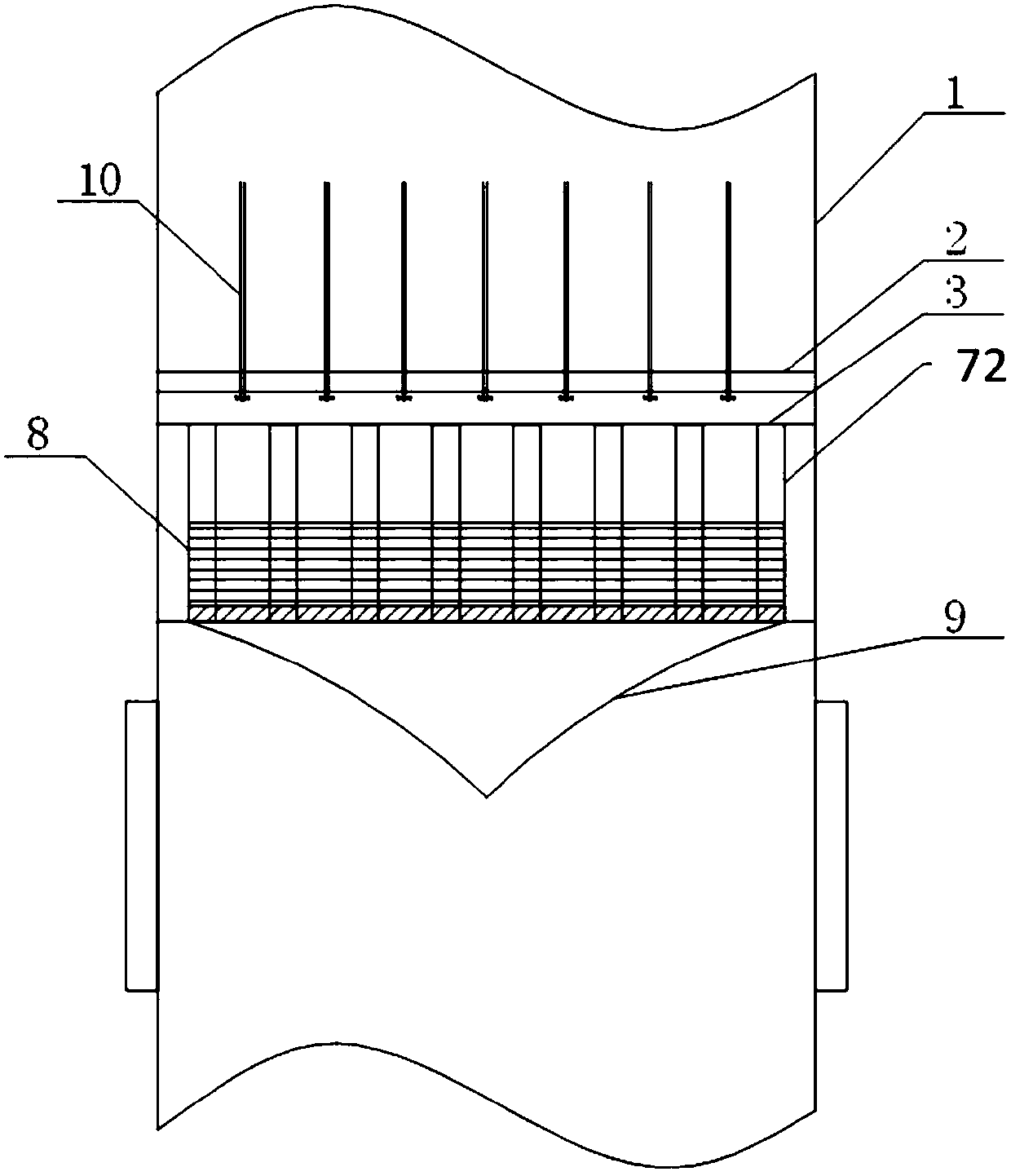

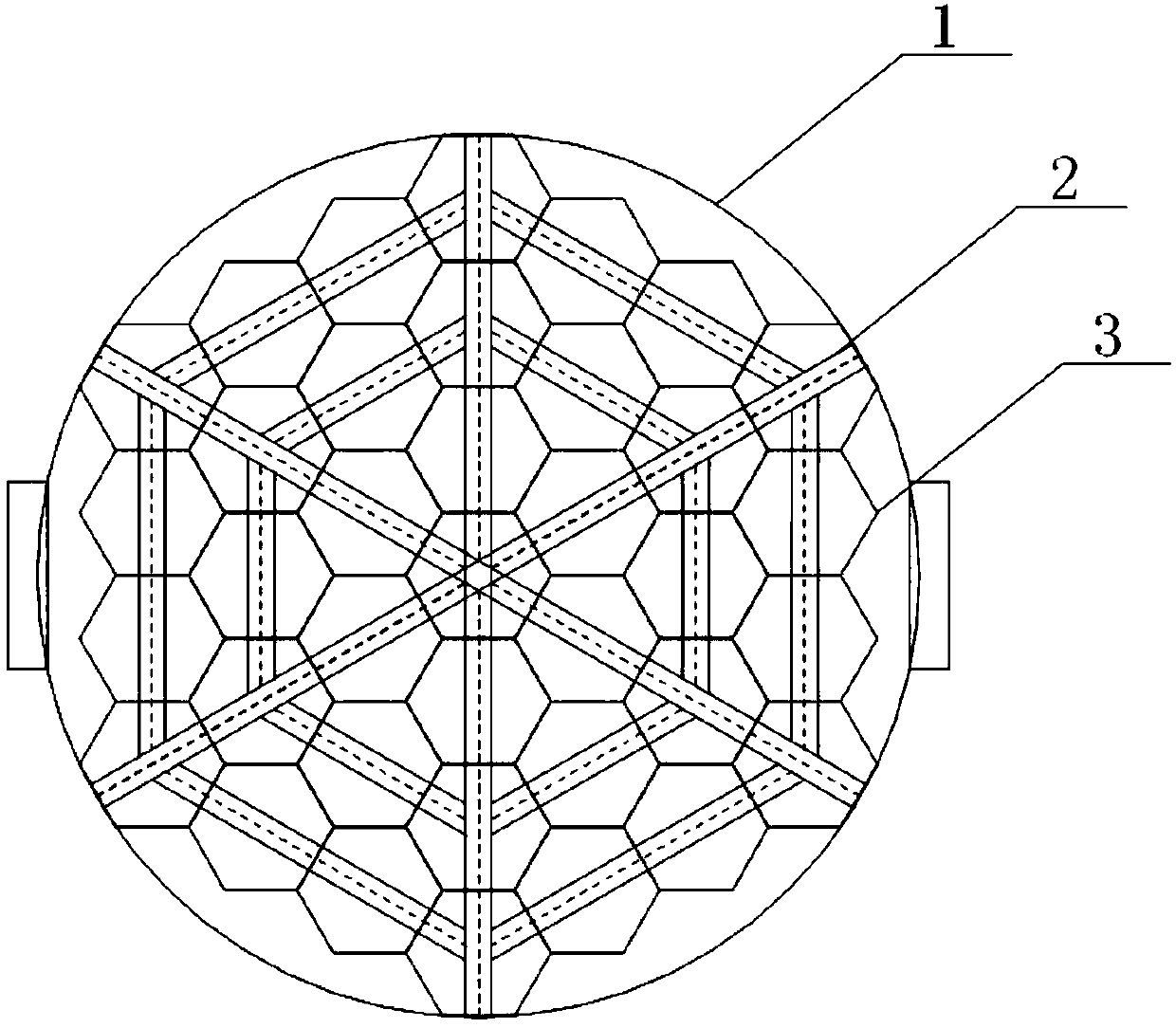

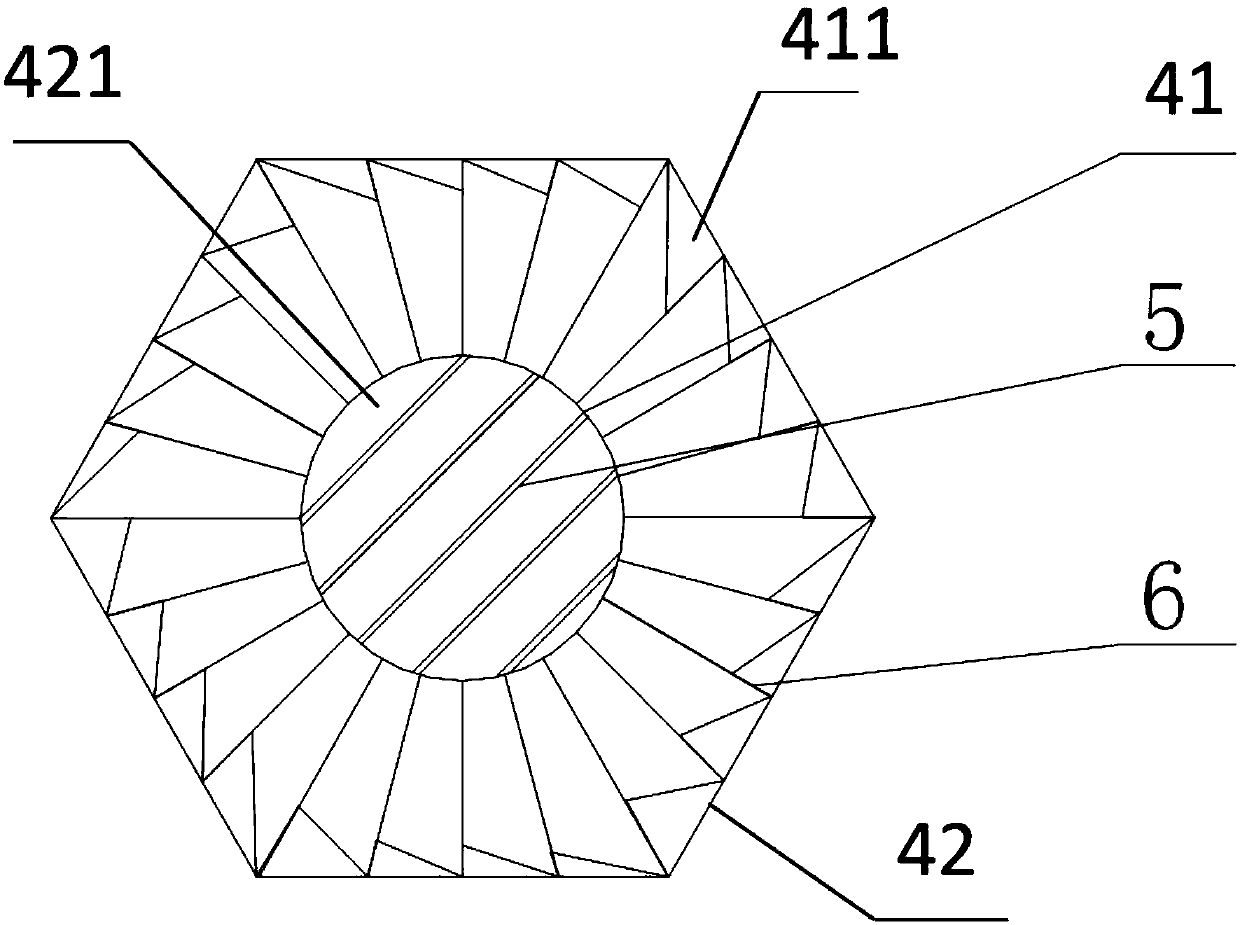

[0028] Such as Figure 1~5 As shown, a preferred embodiment of the present invention provides a suspension type cyclone defogging system, comprising a fixed beam 2 fixedly installed in the chimney 1 and a cyclone demisting device connected with the fixed beam 2, the cyclone demisting device The fog device is suspended below the fixed beam 2 . Wherein, the swirling flow defogging device includes one or more defogging components 3 and a plurality of defogging channels, and the defogging components 3 sequentially include a first wall 41, a first vane 6, a second wall 42 and a second vane from outside to inside. 5. The defogging channel includes a first channel 411 and a second channel 421. The first channel 411 is defined by the first wall 41, the first blade 6 and the second wall 42. The second channel 421 is defined by the second wall 42 and the second wall. Two blades 5 are defined. In this embodiment, since the swirling flow defogging device is installed in the chimney 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com