Silicon-rich and magnesium-rich nickel slag clinker-free non-shrinking cement and preparation method thereof

A technology without clinker and nickel slag, applied in the field of building materials, can solve the problems of hard-to-gel materials and low hydration activity of nickel slag, and achieve the effects of simple preparation process, improved hydration activity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be clearly and completely described below in conjunction with specific embodiments.

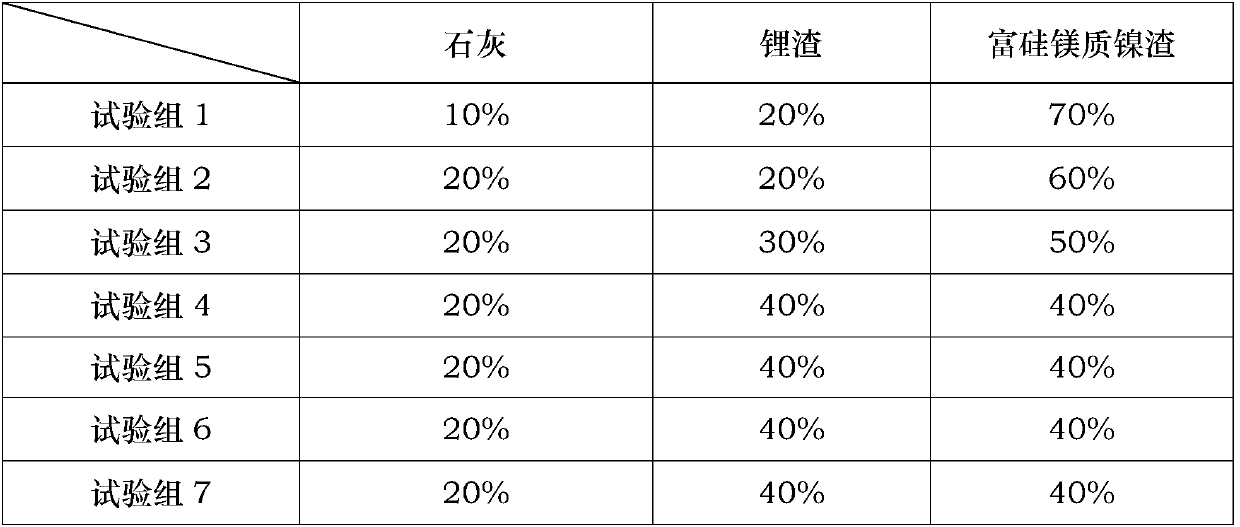

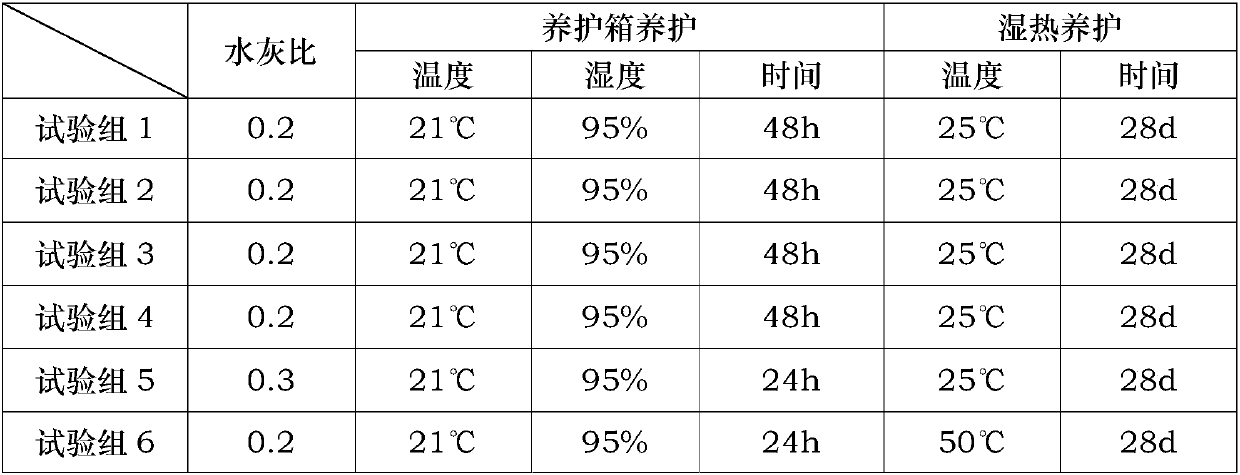

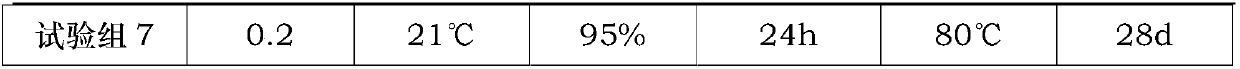

[0021] The hardening shrinkage of Portland cement is its serious shortcoming. It will cause the cement to be unsuitable for making super-long components, and the cement components will produce micro-cracks, etc., which seriously limits the scope of use of cement. The production of silicon-rich magnesium nickel slag is huge, and it is urgent to use it effectively in large quantities. The main chemical composition of silicon-rich magnesium nickel slag is SiO 2 , MgO, so these two components must be fully utilized to be considered to be effectively utilized. The main mineral composition of nickel slag is monoclinic enstatite MgSiO 3 , and contains a small amount of orthorhombic enstatite MgSiO 3 and forsterite (Mg Fe) 2 SiO 4 . Based on this, the present invention uses lime and lithium slag as the alkaline activator, by controlli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com