Low surface temperature polypropylene composition and preparation method and application thereof

A polypropylene composition, low surface technology, applied in the field of plastic modification, can solve problems such as low surface temperature, and achieve the effects of reducing the frequency of use, reducing the temperature in the car, and improving the near-infrared reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

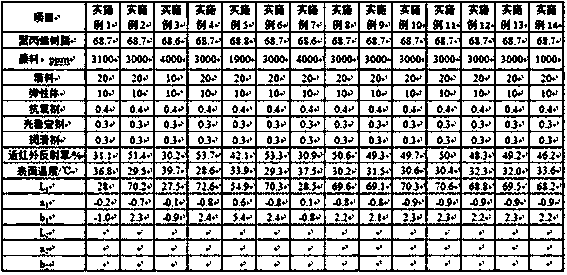

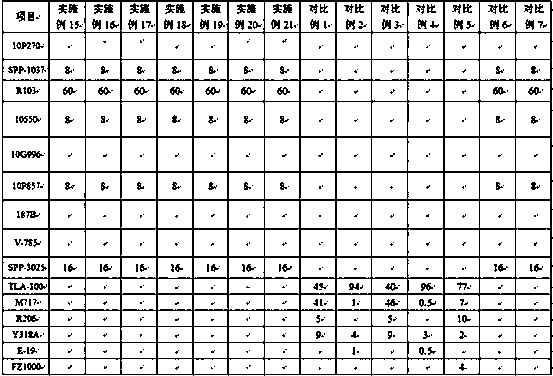

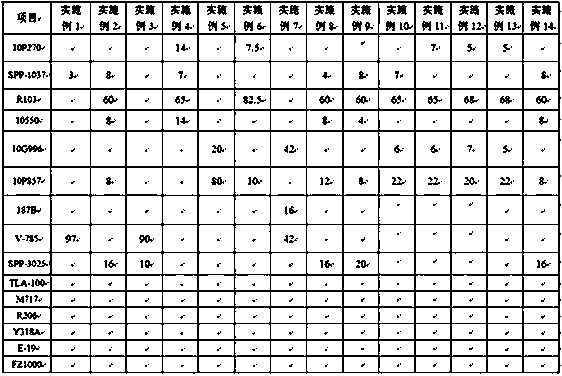

[0021] The present invention will be further described below through specific embodiments. The following examples are preferred implementation forms of the present invention, but the implementation manners of the present invention are not limited by the following examples.

[0022] raw material

[0023] The raw materials used in the examples and comparative examples are now described as follows, but not limited to these materials:

[0024] Polypropylene, PP BX3800, Korea SK Company, tested according to ASTMD1238, the melt flow rate is 28.4 g / 10min;

[0025] Elastomer, DF610, Mitsui Chemicals;

[0026] Filler, talcum powder TYT-777A, Beihai Group;

[0027] Antioxidant, 1010, 168, BASF Corporation;

[0028] Light stabilizer, 3808PP5, Cytec Chemical Co., Ltd.;

[0029] Lubricant, TR451, American Struktol Company;

[0030] Titanium dioxide, TLA-100, Panzhihua Tianlun Chemical Co., Ltd.;

[0031] Carbon black, M717, CABOT company;

[0032] Titanium chrome brown, R206, Xiangt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com