Weather-proof steel plate and manufacturing method thereof

A manufacturing method and steel plate technology, which is applied in the field of alloy steel plates, can solve the problems of ignoring the ductility and plasticity and welding performance of steel plates, failure to balance performance and production costs, and complicated manufacturing processes, so as to achieve shortened production cycles, good weldability, and weldability. The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment.

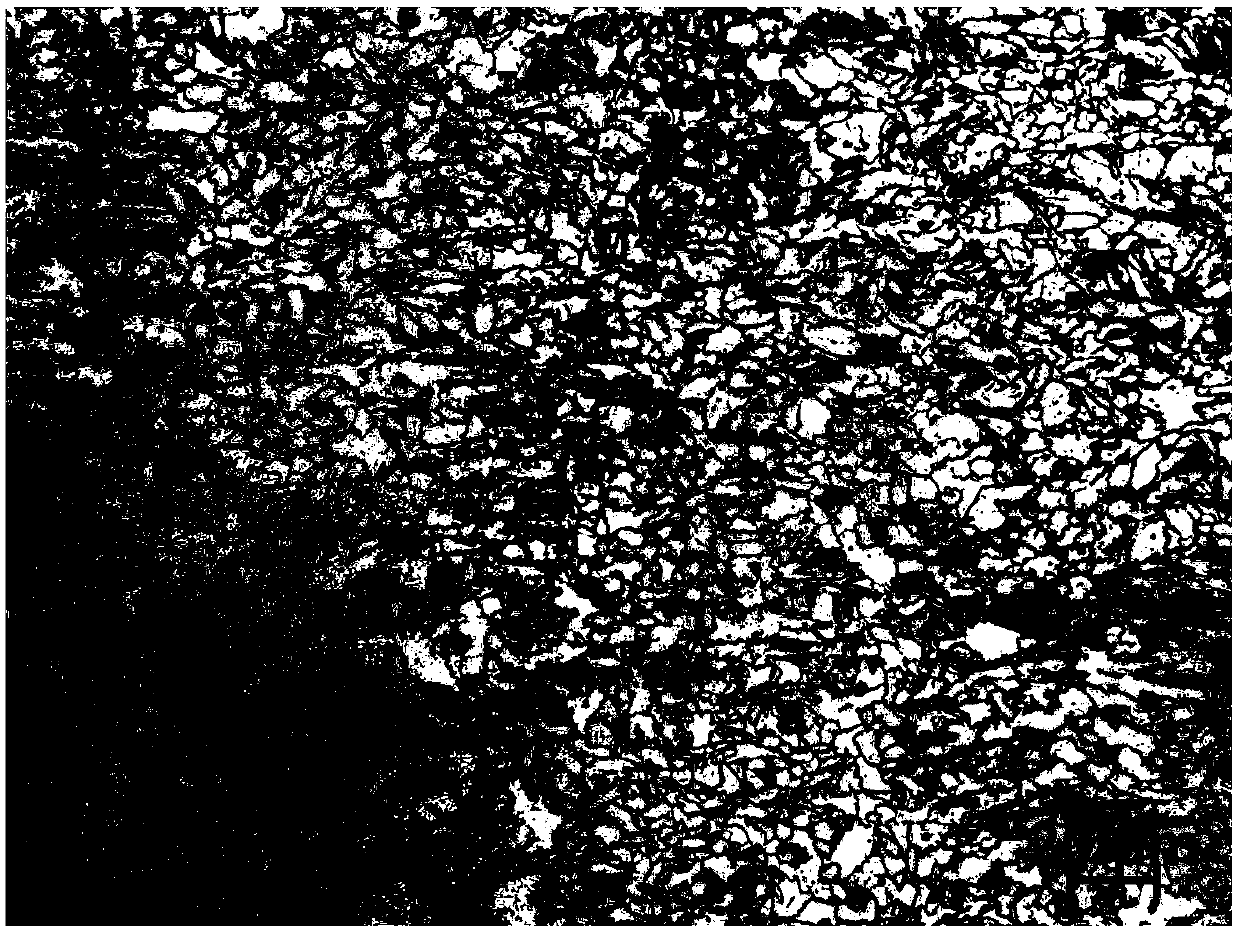

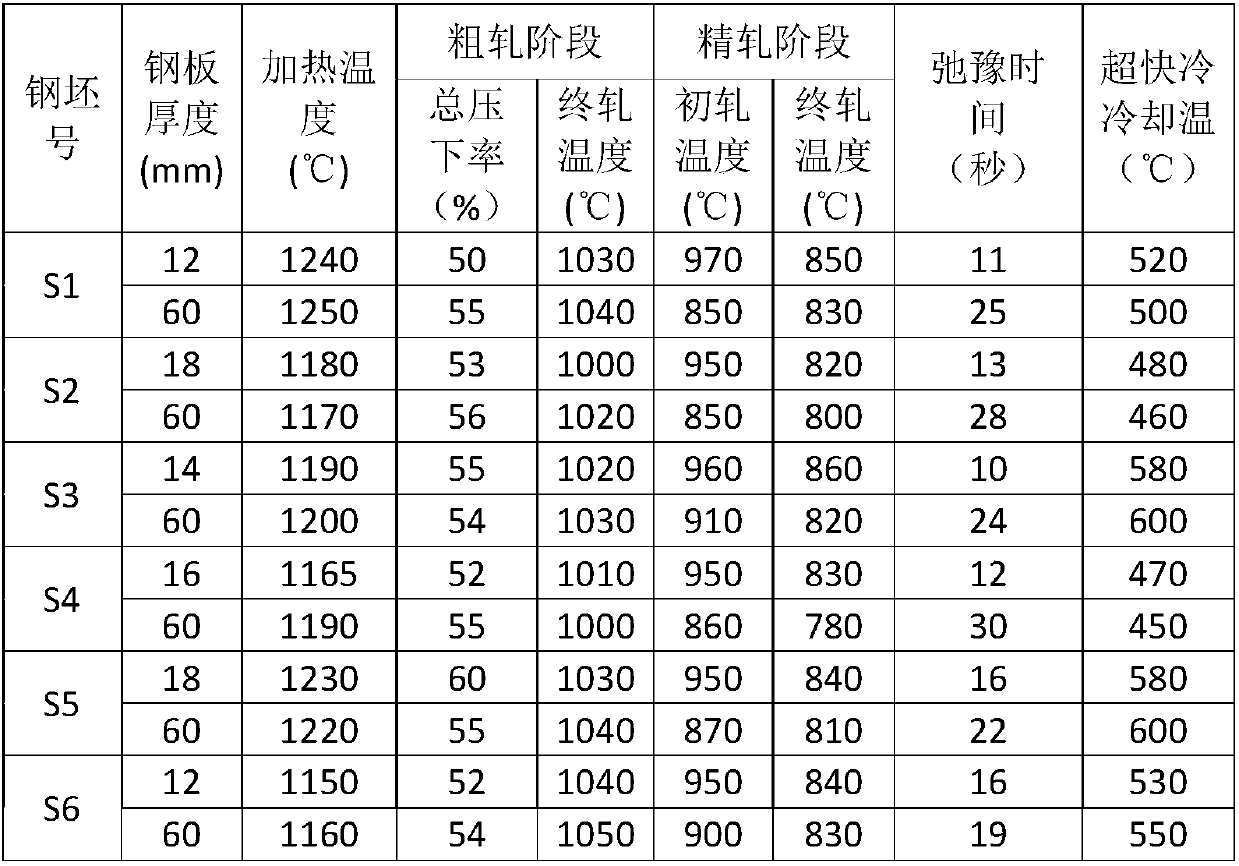

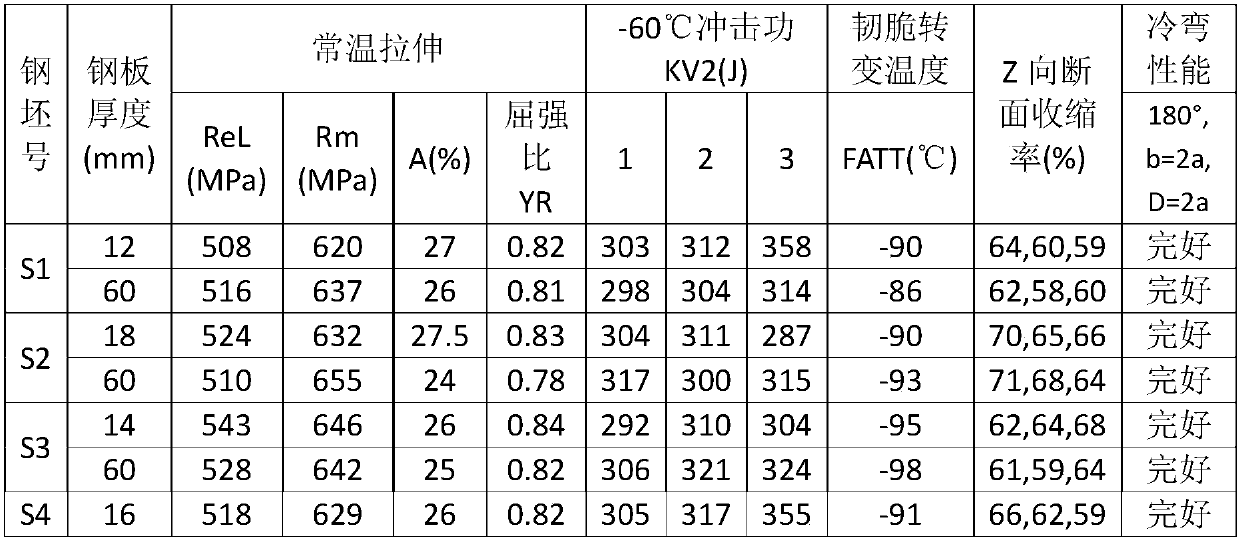

[0028] Using the weather-resistant steel plate manufacturing method of the present invention, the weather-resistant steel plate of the present invention is obtained through the processes of smelting, refining, continuous casting, heating and rolling; wherein, during the heating process, the cast slab is heated to the complete austenitization temperature The rolling process adopts a two-stage rolling process in the austenite recrystallization zone and austenite non-recrystallization zone, and can also be a two-stage rolling process of rough rolling and finishing rolling. The starting temperature of the finishing rolling stage is 850-970°C. The final rolling temperature is 780-860°C, stay for 10-30 seconds after rolling, then cool to 450-600°C through ultra-fast cooling technology, and then air-cool to room temperature, such as figure 1 , the metallographic photos show that the microst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com