Ring-cable joint for irregular plane cable net

An irregular, ring-cable technology, applied in the dome roof structure, building components, arched structure, etc., can solve the problems of increasing the difficulty of processing and manufacturing ring-cable joints, increasing the cost of joint processing and manufacturing, and unfavorable standardized production of joints. Simple structure, convenient operation, saving design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

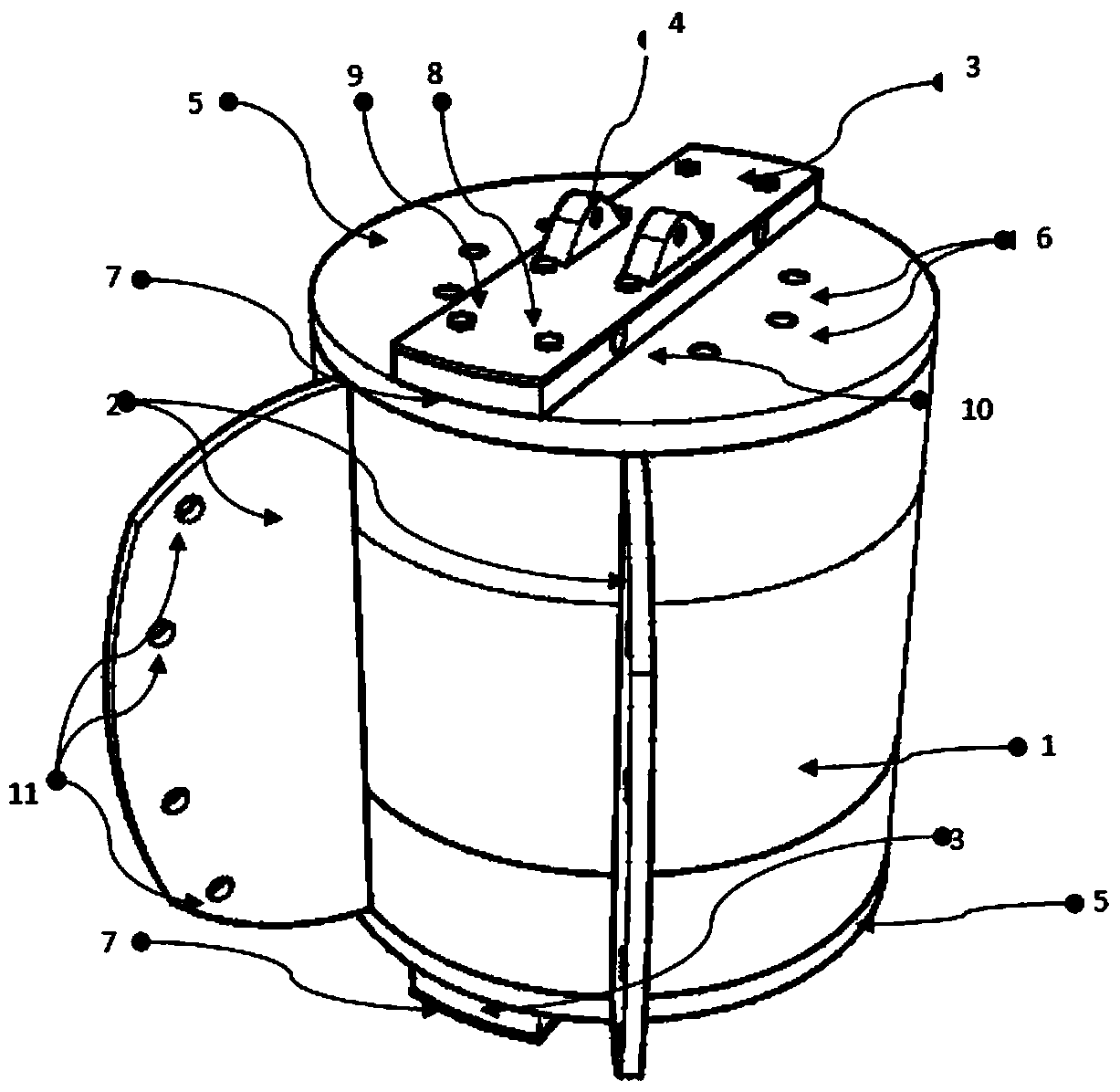

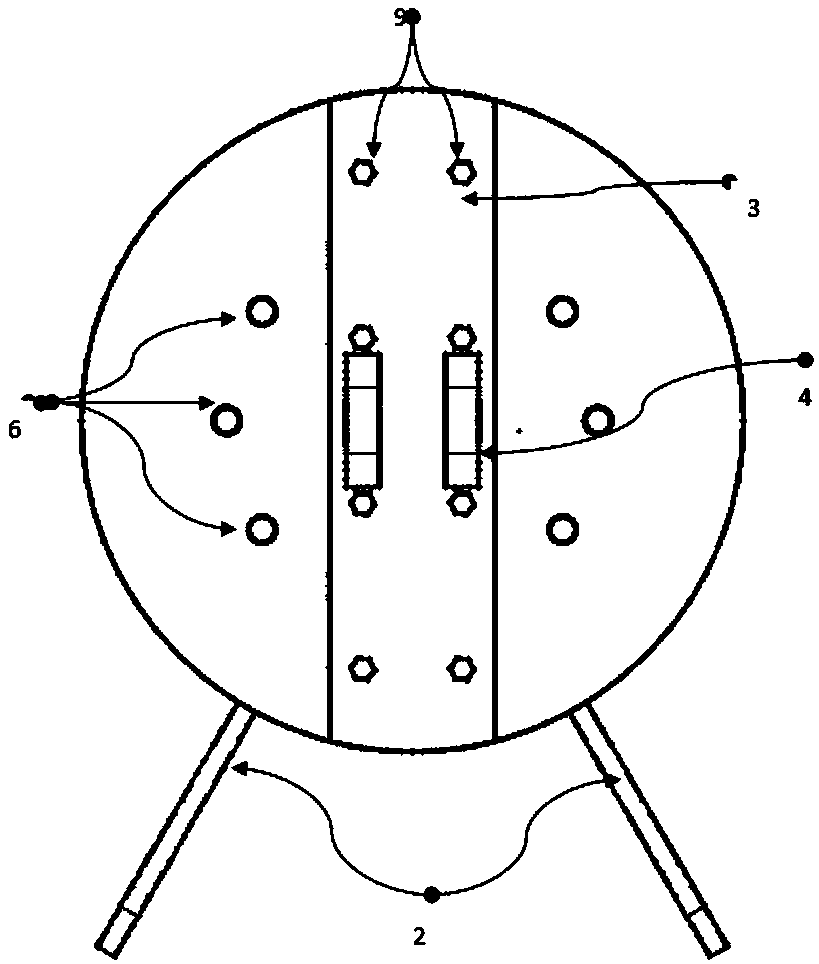

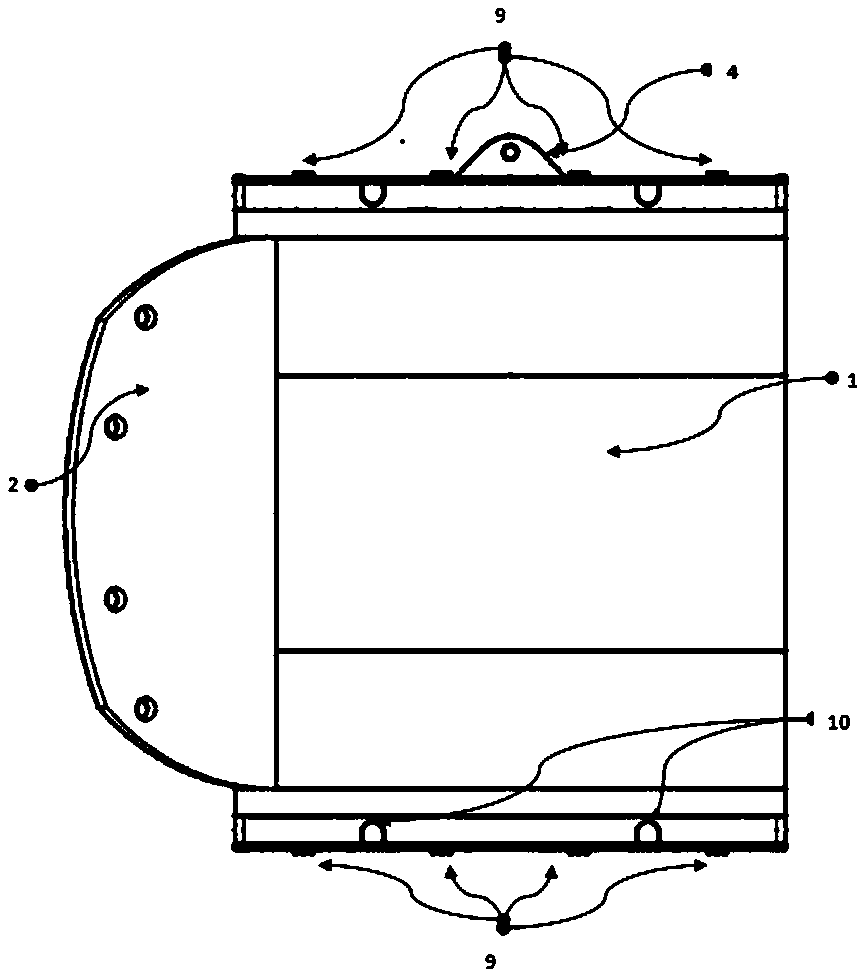

Embodiment 1

[0019] The main structure of this embodiment includes: pin shaft connecting body 1, oblique cable ear plate 2, hoop cable connecting body 3, pin shaft end plate 5, countersunk bolt 6, high-strength bolt 9, hoop cable hole 10, and oblique cable connecting hole 11 ; The pin connecting body 1 is located at the center of the node, and it is respectively welded or bolted to the oblique cable lug plate 2 and the ring cable connecting body 3; the top and bottom of the pin connecting body 1 are symmetrically provided with a pin end plate 5, and the pin shaft The end plate 5 is fixed to the pin shaft connecting body 1 through the countersunk bolt 6, and is connected to the hoop connecting body 3 through the high-strength bolt 9. The hoop connecting body 3 is composed of the hoop connecting plate 7 and the cover plate 8, and the hoop connecting plate 7 There is a cable hole 10 on the top, and the cover plate 8 is connected with the hoop connecting plate 7 through high-strength bolts 9, w...

Embodiment 2

[0021] The main structure of this embodiment includes: pin shaft connecting body 1, oblique cable ear plate 2, ring cable connecting body 3, vertical bar connecting ear plate 4, pin shaft end plate 5, countersunk bolt 6, high-strength bolt 9, ring cable hole 10. Cable connection hole 11; the pin connector 1 is located at the center of the node, which is welded or bolted to the oblique cable ear plate 2, the ring cable connector 3 and the vertical rod connecting ear plate 4 respectively; the pin connector 1 The top and the bottom are symmetrically provided with pin shaft end plates 5, which are fixed to the pin shaft connecting body 1 by countersunk bolts 6, and connected to the ring cable connecting body 3 by high-strength bolts 9, and the ring cable connecting body 3 is connected by the ring cable The connecting plate 7 and the cover plate 8 are composed, the cable hole 10 is opened on the cable connecting plate 7, the cover plate 8 is connected with the cable connecting plate...

Embodiment 3

[0023] The main structure of this embodiment includes: pin shaft connecting body 1, oblique cable ear plate 2, ring cable connecting body 3, vertical bar connecting ear plate 4, pin shaft end plate 5, countersunk bolt 6, high-strength bolt 9, ring cable hole 10. Cable connection hole 11; the pin connector 1 is located at the center of the node, which is welded or bolted to the oblique cable ear plate 2, the ring cable connector 3 and the vertical rod connecting ear plate 4 respectively; the pin connector 1 The top and the bottom are symmetrically provided with pin shaft end plates 5, which are fixed to the pin shaft connecting body 1 by countersunk bolts 6, and connected to the ring cable connecting body 3 by high-strength bolts 9, and the ring cable connecting body 3 is connected by the ring cable The connecting plate 7 and the cover plate 8 are composed, the cable hole 10 is opened on the cable connecting plate 7, the cover plate 8 is connected with the cable connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com