Integrated drying oven

An integrated oven technology, applied in drying, drying machine, drying solid materials, etc., can solve the problem of high cost of production site use, achieve the effect of small footprint, simple structure, and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

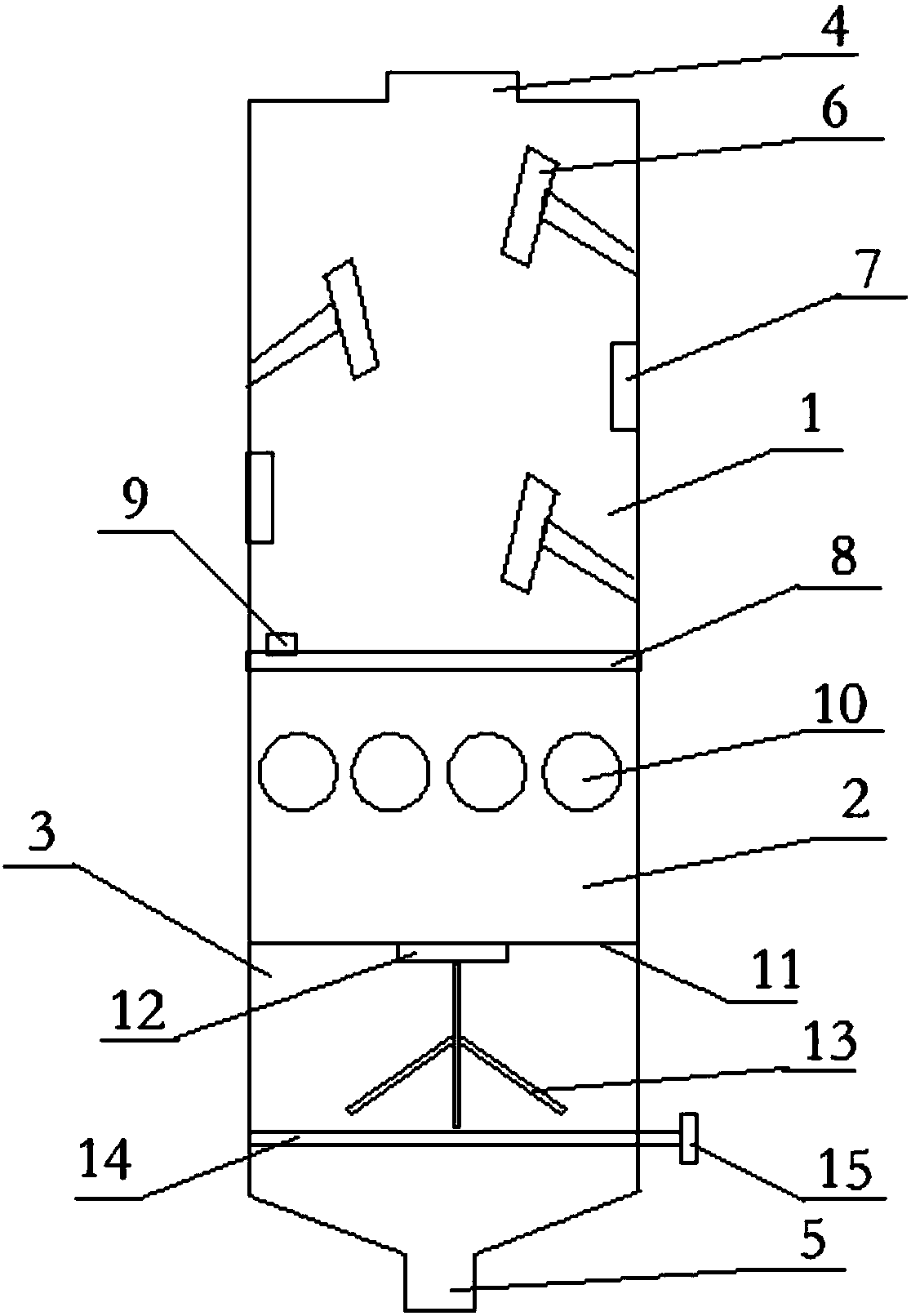

[0016] like figure 1 As shown, an integrated oven includes an oven body, and an insulation layer is provided outside the oven body. The oven body is divided into a transfer chamber 1, a drying chamber 2, and a mixing chamber 3 from top to bottom. The top of the oven body is provided with a feed inlet 4, and the bottom is provided with a tapered outlet 5, and a heating tube 7 and a baffle 6 are arranged on the side wall of the transfer chamber 1 in the oven body, and the baffle 6 are arranged in a staggered manner, the baffles 6 and the heating pipes 7 are arranged in a staggered manner, and under the baffles 6 there is a leaky net 8 for the rubber to pass through, and the mesh of the leaky net 8 is larger than the cross-sectional area of the rubber. A vibrator 9 is provided on the leaking screen 8 to accelerate rubber passing through the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com