Wool-spinning material carrying call system for intelligent AGV

A technology for calling systems and materials, applied in logistics, instruments, data processing applications, etc., can solve problems such as difficult production tasks, warehousing statistics and record errors and negligence, difficulty in satisfying wool spinning production enterprises, etc., to reduce manual operation errors, reduce Production management costs, the effect of improving material handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Specific embodiments of the present invention are described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0055] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

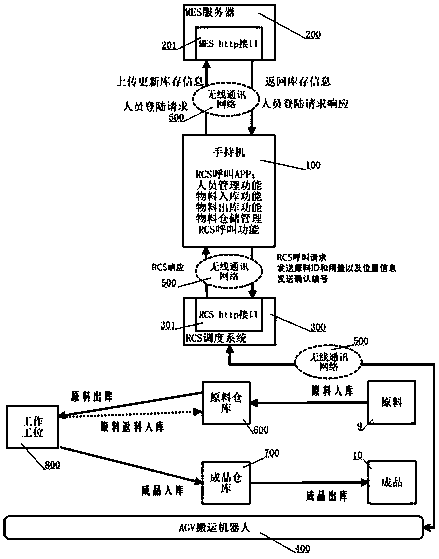

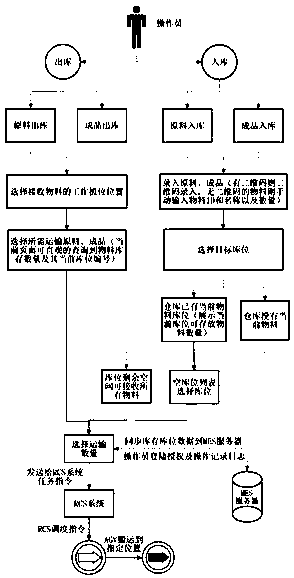

[0056] like figure 1 As shown, an intelligent AGV wool spinning material handling call system mainly includes: handheld machine 100, MES server 200, AGV handling robot 400, RCS robot scheduling system 300, wireless communication network 500, raw material warehouse 600, finished product warehouse 700, worker bit 800;

[0057] The handheld device 100 is used to provide human-computer graphic interaction between the entire system and the operator, storage and delivery maintenan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com