Pneumatic tire

A technology for pneumatic tires and tires, which is applied to pneumatic tires, reinforcement layers of pneumatic tires, special tires, etc., can solve problems such as difficulty in bearing loads, deformation of sidewalls, and difficulty in driving, and achieve the effect of improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

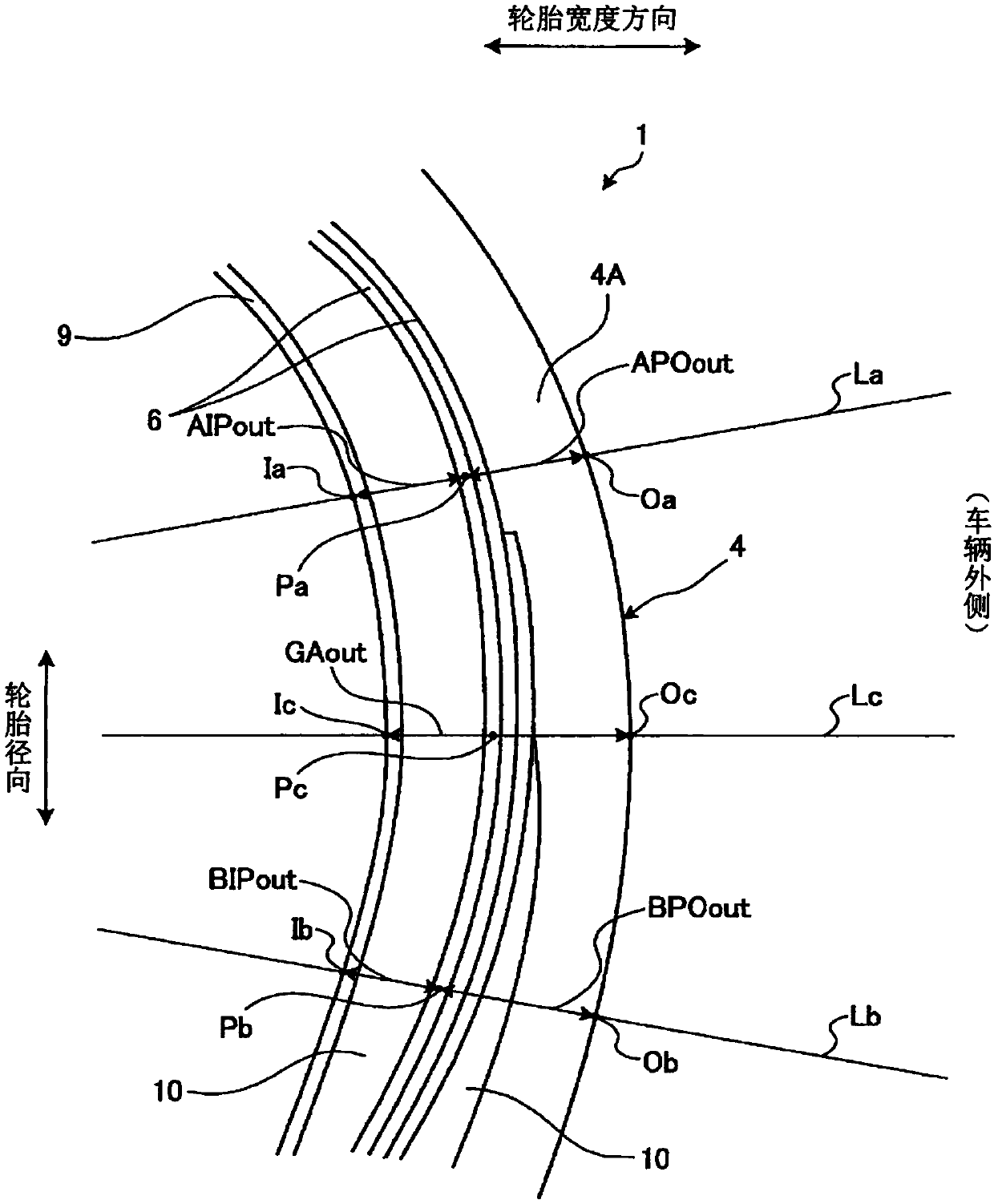

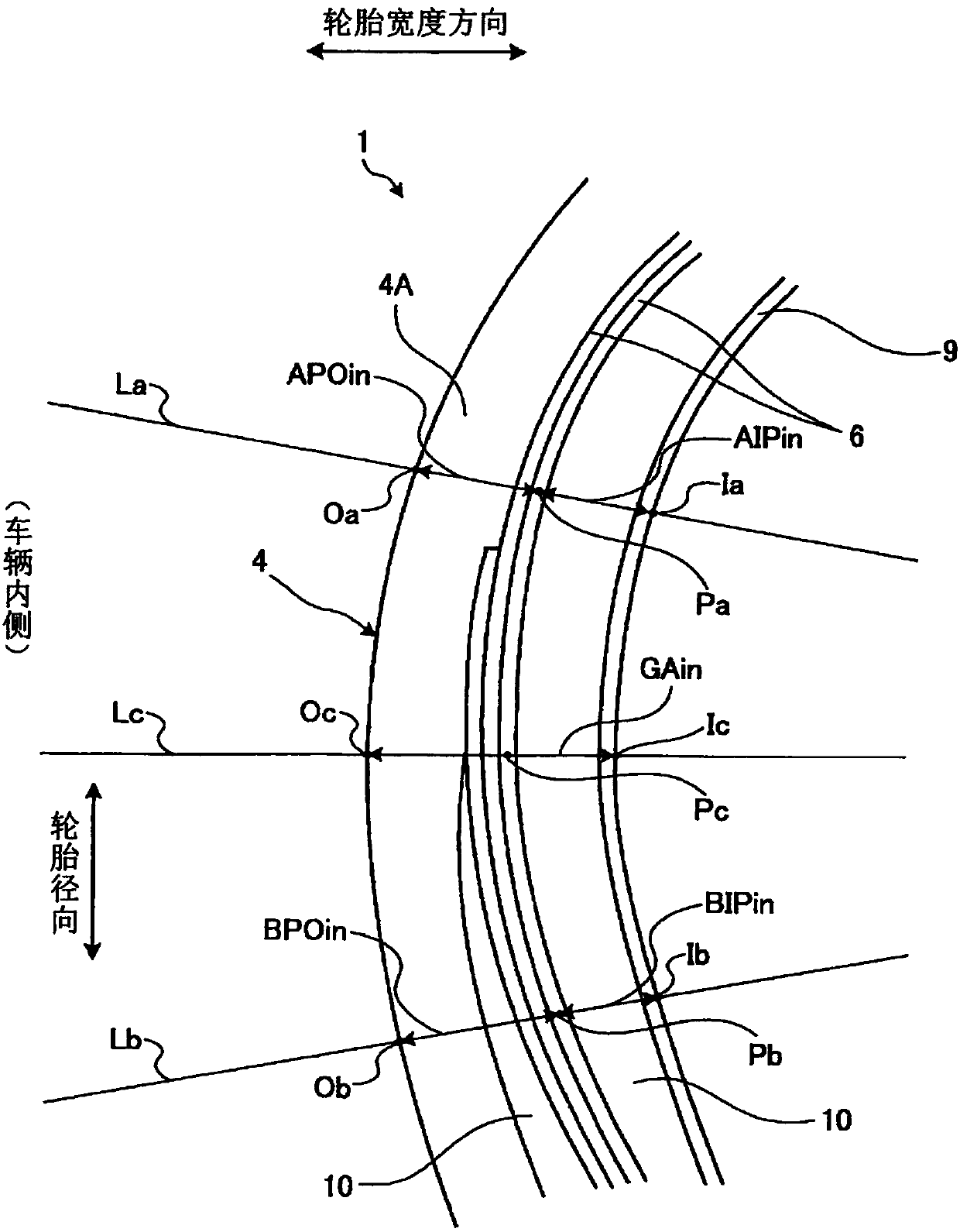

[0104] In this example, performance tests related to run-flat running durability, driving stability, ride comfort, and rolling resistance performance were performed on various pneumatic tires under different conditions (refer to Figure 4 ).

[0105] In this performance test, a pneumatic tire (test tire) with a tire size of 235 / 50R18 was assembled on a regular 18×7.5J rim.

[0106] The evaluation method of run-flat running durability is: set the above-mentioned test tire to an internal pressure of 0kPa, and implement it on the test track under ECE30 conditions. The running distance was evaluated by an index evaluation based on the conventional example (100). The larger the value, the longer the running distance, and the better the run-flat running durability.

[0107] The evaluation method of driving stability is: fill the above-mentioned test tire with normal internal pressure (230kPa), and test vehicle (domestic 2000cc SUV (Sport Utility Vehicle)) on a dry road at a speed of 60 [k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com