Printing method using two lasers

A laser printing and laser technology, applied in lasers, laser parts, removing conductive materials by mechanical methods, etc., can solve problems such as incompatibility, inability to eliminate metal stars, high particle pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

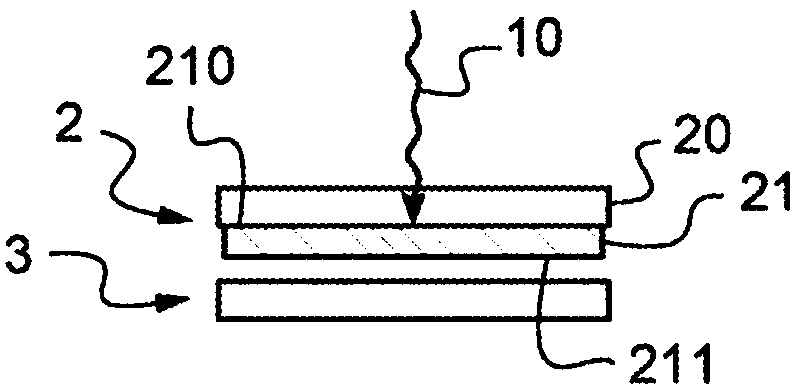

[0047] refer to figure 1 , the basic principles of the LIFT method known in the prior art will now be described.

[0048] therefore, Figure 1a A laser energy source 1 capable of generating laser energy 10 is shown.

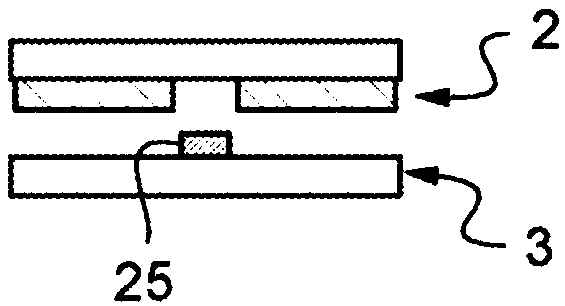

[0049] It also shows a target substrate 2 comprising a transparent substrate 20 and a coating 21 consisting of a thin liquid film.

[0050] Figure 1a A receiver substrate 3 is also shown.

[0051] The target substrate 2 is located between the laser energy source 1 and the receiver substrate 3 .

[0052] Furthermore, a coating 21 is formed on the surface of the substrate 20 facing the receiver substrate 3 . Coating 21 thus comprises a surface 210 in contact with substrate 20 and a surface 211 facing receiver substrate 3 .

[0053] The coating 21 can consist of an ink based on silver or copper nanoparticles.

[0054] Once the target substrate 2 and the receiver substrate 3 as Figure 1a The coating 21 is irradiated by the laser energy source 1 in the arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com