Ozone denitration pre-sprinkling absorption device

An absorption device and pre-spraying technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, can solve the problems of low denitrification efficiency and inability to completely absorb nitrogen oxides, so as to improve the denitrification efficiency without modifying the boiler Main body, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

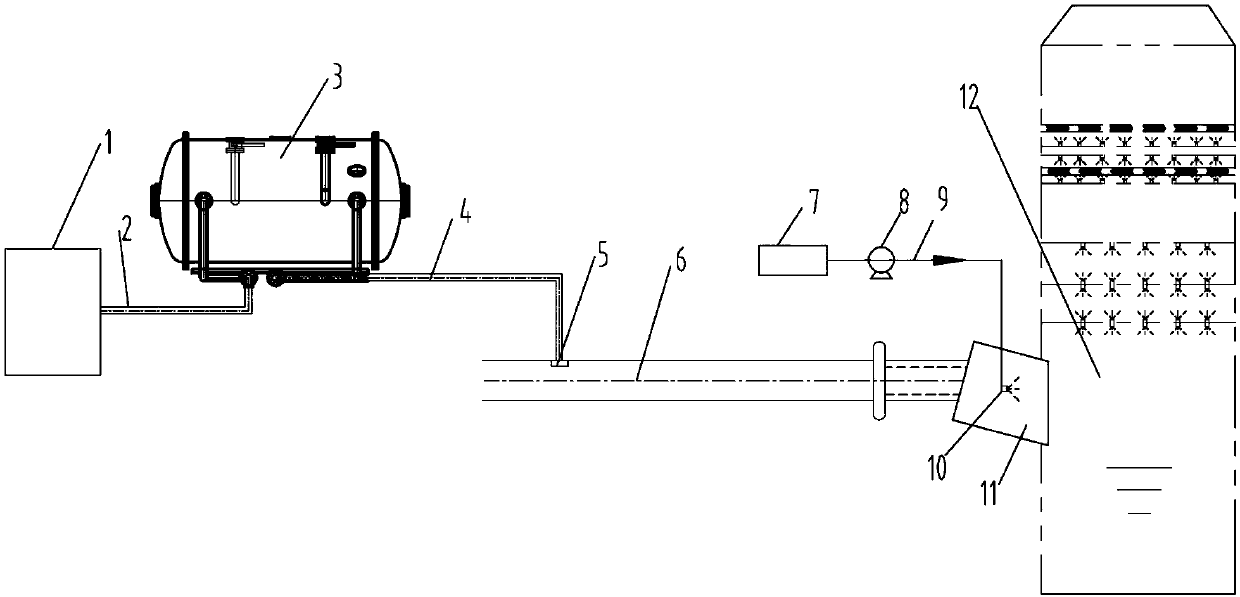

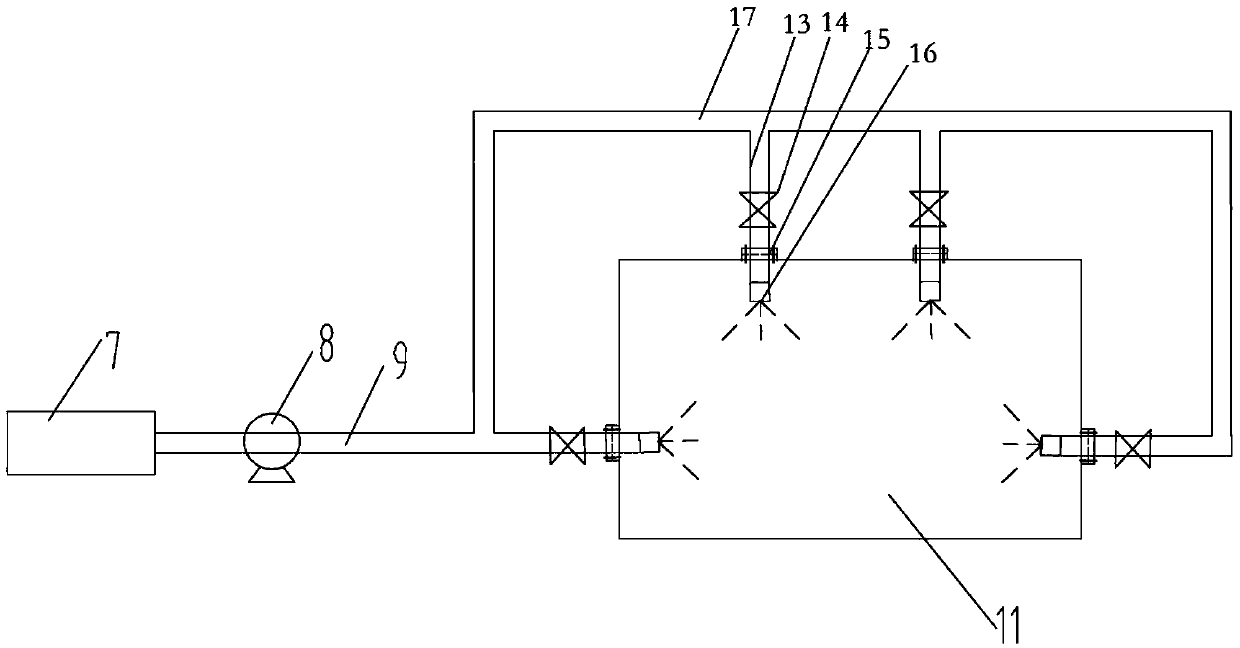

[0032] Such as Figures 1 to 2 As shown, an ozone denitrification pre-spray absorption device includes an oxygen preparation device 1, an oxygen delivery pipeline 2, an ozone generator device 3, an ozone delivery pipeline 4, an ozone gas distribution device 5, a main flue 6, a process water tank 7, Process water pump 8, process water pipeline 9, pre-spray absorption device 10, desulfurization inlet flue 11, wet desulfurization device 12, the oxygen preparation device 1 and the ozone generator device 3 are connected through the oxygen delivery pipeline 2, and the ozone generation The device 3 is connected with the ozone gas distribution device 5 through the ozone delivery pipeline 4, the ozone gas distribution device 5 is connected with the pre-spray absorption device 10 through the main flue 6 and the desulfurization inlet flue 11, the process water tank 7, the process water pump 8 and the pre-spray The spray absorption device 10 is connected through the process water pipeline...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, except that in Embodiment 2, the horizontal distance between the nozzle 16 and the ozone distribution device 5 is 1 meter.

Embodiment 3

[0037] This embodiment is basically the same as Embodiment 1, except that in Embodiment 3, the horizontal distance between the nozzle 16 and the ozone distribution device 5 is 2 meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com