Branching tensioner

A tension machine and branching technology, which is applied to overhead line/cable equipment, conveying filamentous materials, thin material processing, etc., can solve the problems of not having a special tension machine for production, and achieve improved construction efficiency, reasonable distribution, and environmental damage small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

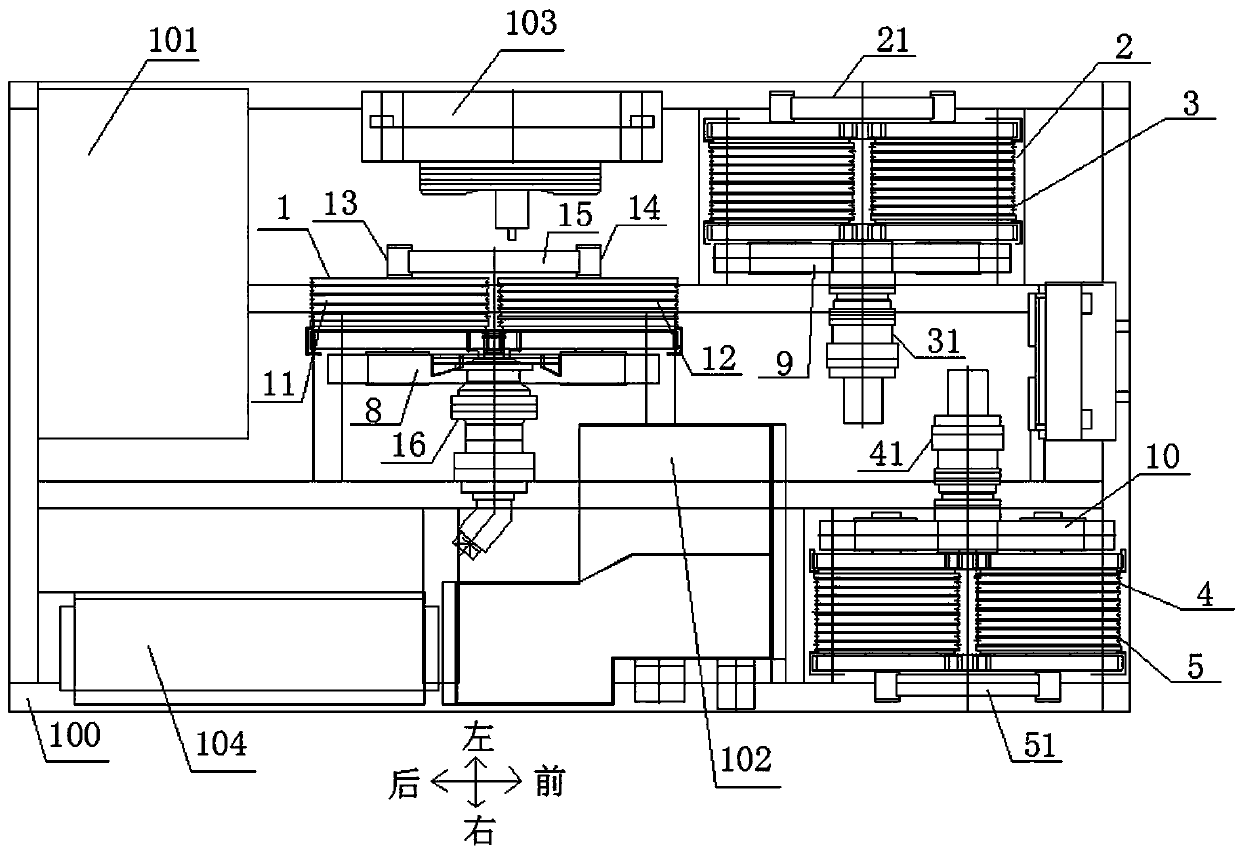

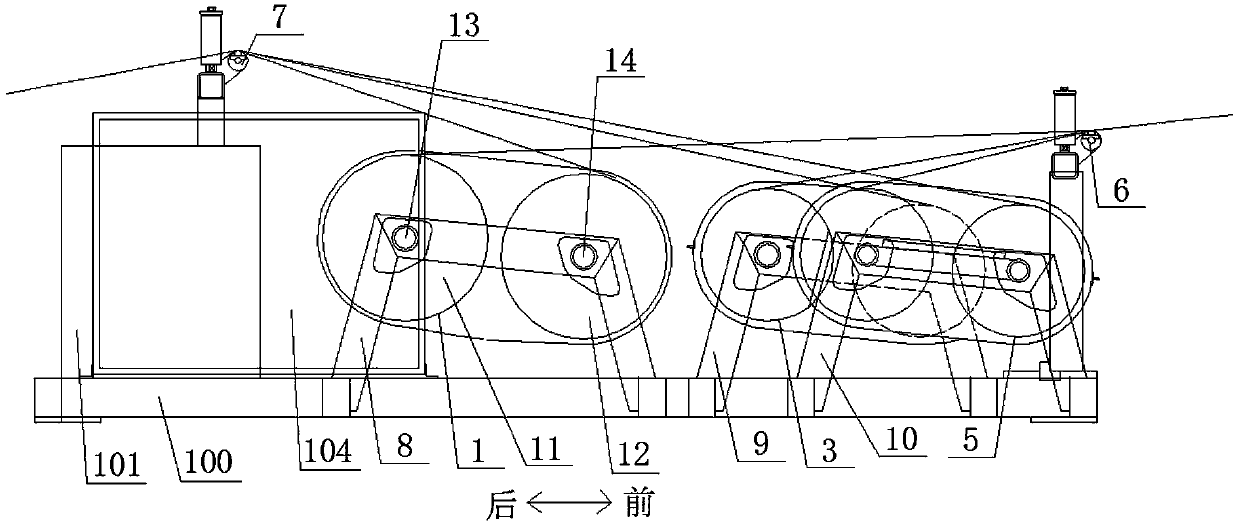

[0026] Such as figure 1 , figure 2 As shown, the branching tension machine of the present invention includes a base 100, and the branching tension machine is placed on the ground through the base 100, and the branching tension machine is used to display a plurality of guide wires with the same conveying direction, and the guide wires conveyed The direction is the front-to-back direction, and the horizontal direction perpendicular to the guide wire conveying direction is the left-right direction, that is, the directions shown by the arrows in the figure are the front, rear, left, and right directions. The base 100 is provided with a first set of tension wheels 1. The second group of tension wheels 2, the third group o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com