Texture regulation and control method and device of external energy field module to high throughput thin film

An energy field and high-throughput technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve problems such as low degree of crystallization, poor density, and fuzzy intercrystalline interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

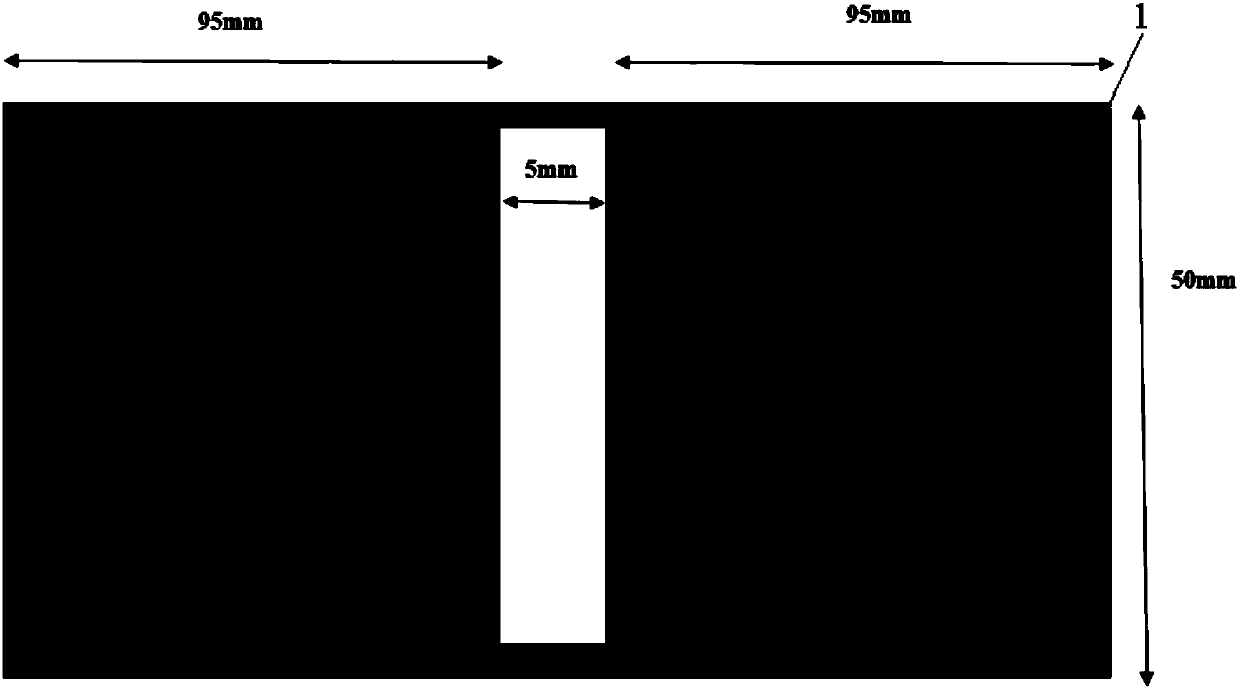

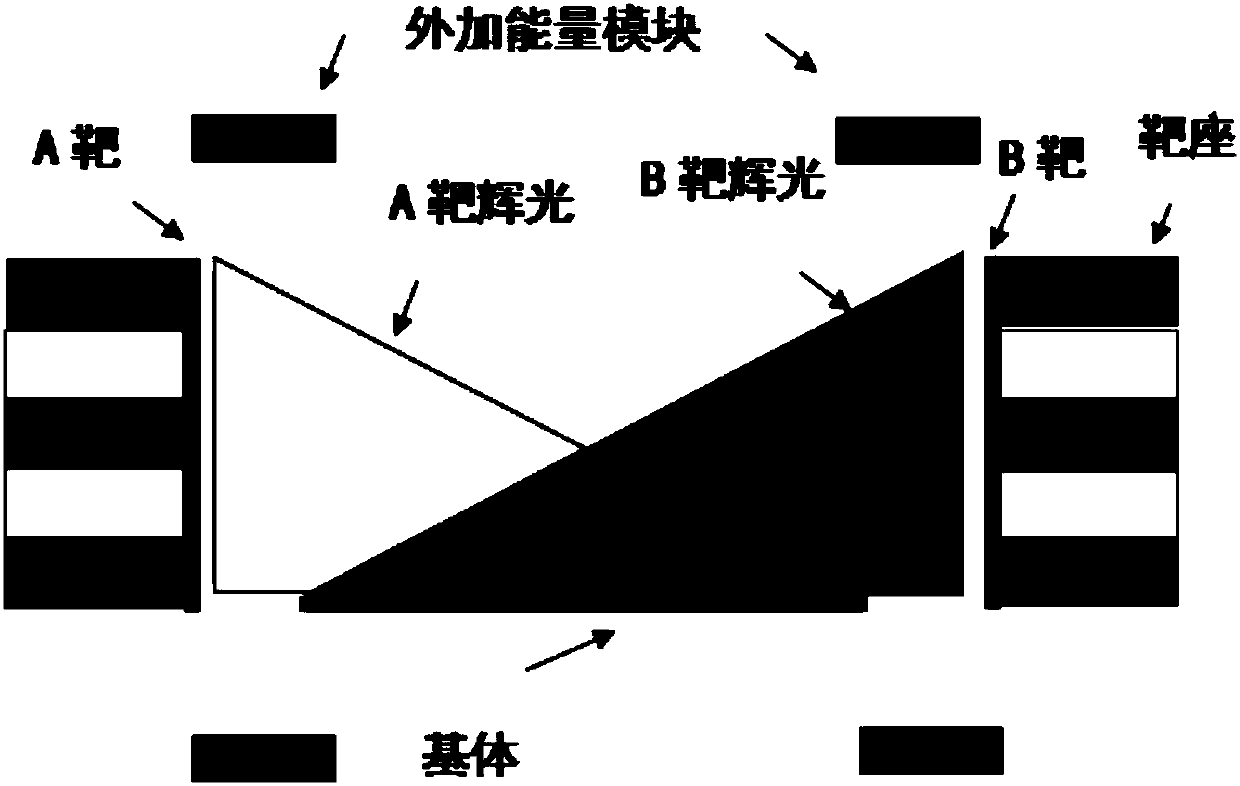

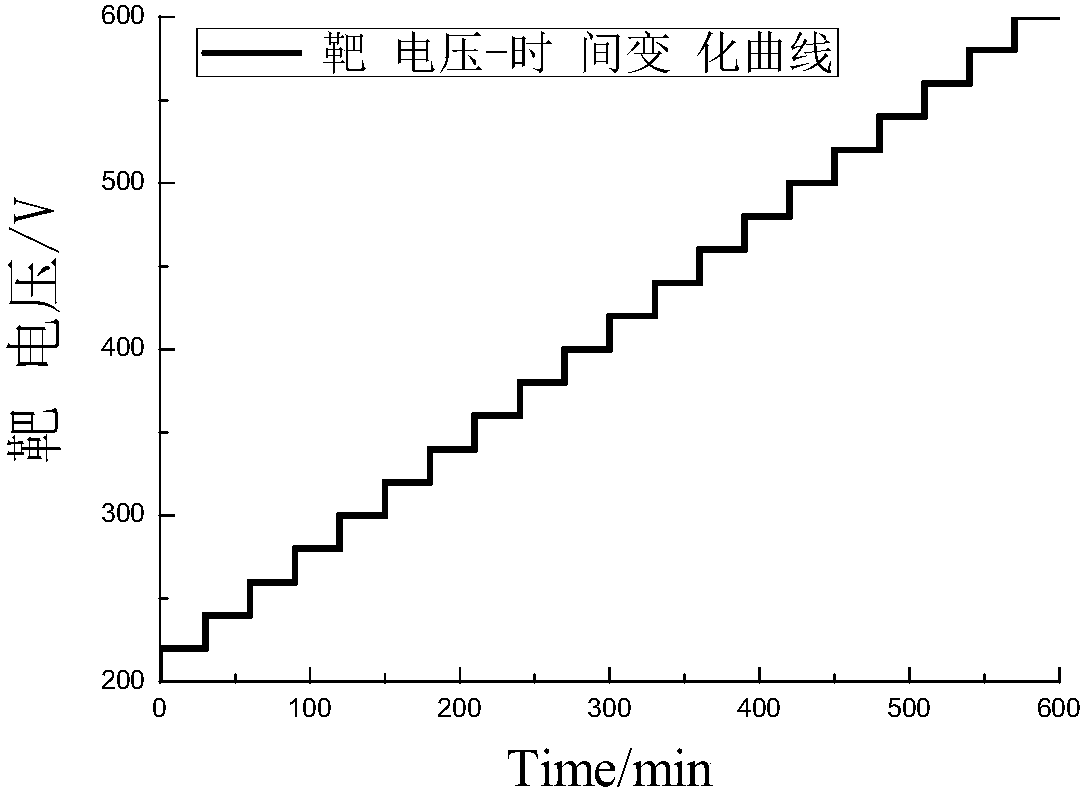

[0056] The substrate for preparing thin film samples is 304 stainless steel, and the substrate size is 100mmX 40mmX2mm. A layer of thin film with composition gradient is prepared on the substrate by the magnetron co-sputtering method of Cr target and Ni target, and the movement of the mask and the regulation of the target voltage The films on the surface of the substrate are deposited sequentially from left to right. The width of the mask slit is 5 mm, and the deposition time at each position is 30 minutes. Films with different deposition times have different target voltages, so films with different deposition times and deposition positions have different composition and microstructure. After the high-throughput thin film is prepared, use XRD and scanning electron microscopy to observe the surface and cross-sectional morphology, the crystal state of the thin film, and measure the composition distribution. Finally, the wire beam electrode is used to measure the potential and cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com