Three-phase electricity over-voltage, under-voltage and default phase alarm circuit based on peak voltage detection

A peak voltage and alarm circuit technology, applied in the direction of measuring current/voltage, measuring device, measuring electrical variables, etc., can solve problems such as abnormal welding, poor anti-interference ability, and user loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

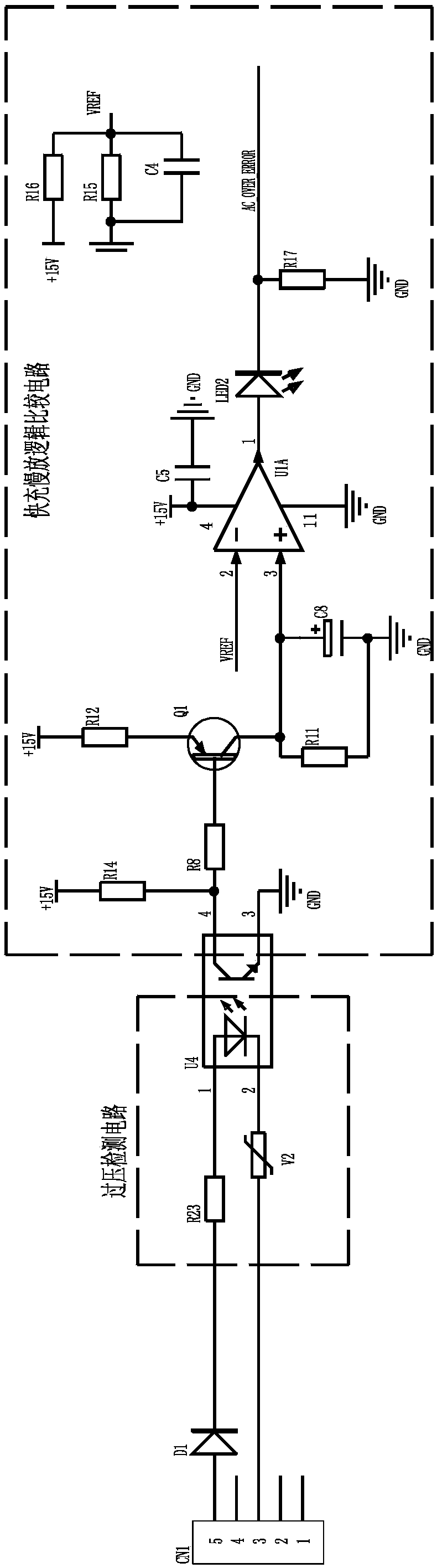

[0077] Such as figure 1 As shown, the three-phase overvoltage alarm circuit based on peak voltage detection includes:

[0078] The No. 1 diode D1 is used to lock the waveform and is connected to any phase of the three-phase power; the No. 1 diode D1 locks two phases of the three-phase power for detection to prevent the other phase of electrical signals from entering.

[0079] In the overvoltage detection circuit, one of its input terminals is connected to the first diode D1, and the other is connected to any phase of the other two phases of the three-phase power supply. When the voltage exceeds the threshold value, the output terminal of the overvoltage detection circuit is turned on; The voltage detection circuit mainly includes a current limiting resistor R23, an optocoupler U4, and a piezoresistor V2. The positive pole of the optocoupler U4 is connected to the resistor R23, and the negative pole is connected to the varistor V2. The characteristic of the varistor is that a...

Embodiment 2

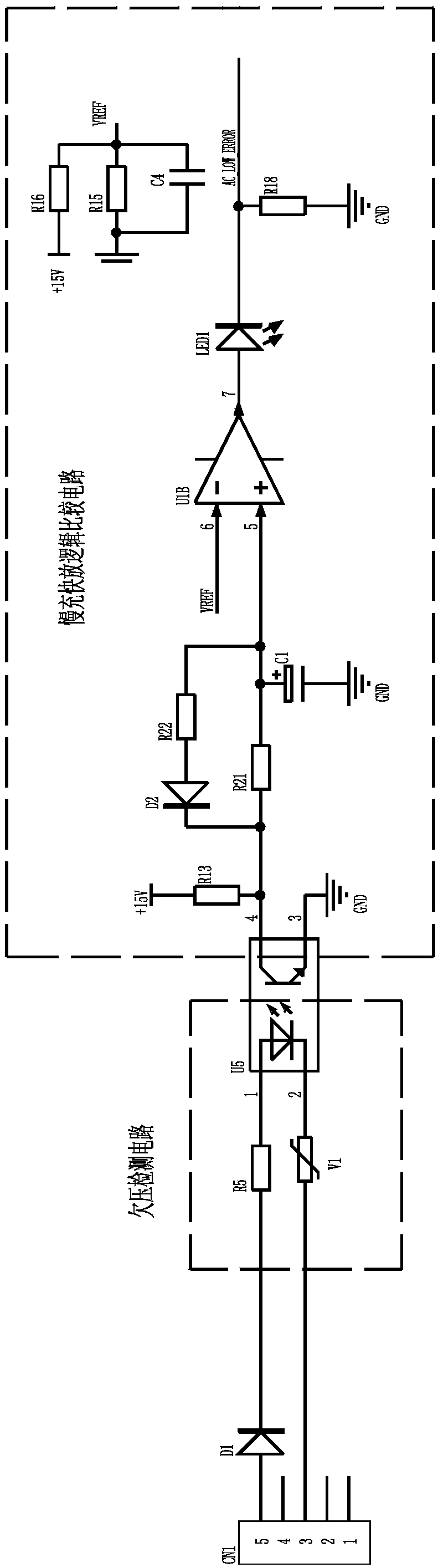

[0083] Such as figure 2 As shown, the three-phase undervoltage alarm circuit based on peak voltage detection includes:

[0084] The No. 1 diode D1 is used to lock the waveform and is connected to any phase of the three-phase power; the No. 1 diode D1 locks two phases of the three-phase power for detection to prevent the other phase of electrical signals from entering.

[0085] One of the input ends of the undervoltage detection circuit is connected to the first diode D1, and the other is connected to any phase of the other two phases of the three-phase power supply. When the voltage exceeds the threshold value, the output end of the overvoltage detection circuit is turned on. The undervoltage detection circuit mainly includes a current limiting resistor R5, an optocoupler U5, and a piezoresistor V1. The positive pole of optocoupler U5 is connected to resistor R5, and the negative pole is connected to piezoresistor V1. The principle of the undervoltage detection circuit is t...

Embodiment 3

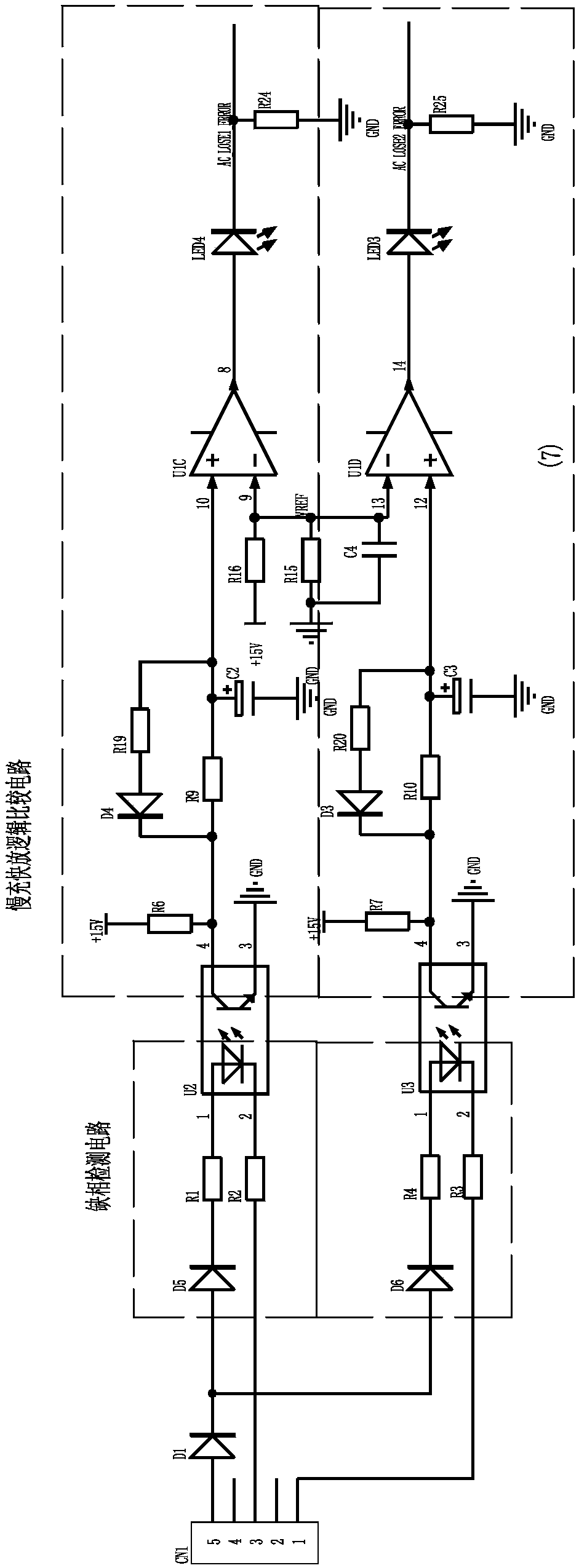

[0089] Such as image 3 As shown, the three-phase electric phase loss alarm circuit based on peak voltage detection is characterized in that it includes a diode No. 1 and two phase loss alarm branches, wherein,

[0090] The No. 1 diode D1 is used to lock the waveform and is connected to any phase of the three-phase power; the No. 1 diode D1 locks two phases of the three-phase power for detection to prevent the other phase of electrical signals from entering.

[0091] Each phase loss alarm branch includes:

[0092] Phase loss detection circuit, one of the input ends of the two phase loss detection circuits is connected to the No. 1 diode, and the other of the input ends of the two phase loss detection circuits is respectively connected to one phase of the other two phases of the three-phase power supply. When the voltage exceeds the threshold , the output terminal of the overvoltage detection circuit is turned on. The 1 / 3 / 5 pins of the plug CN1 in the phase loss detection cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com