Voltage compensation device, voltage compensation method and display device

A voltage compensation and display device technology, applied to static indicators, instruments, etc., to achieve the effect of improving image display quality, less time-consuming, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

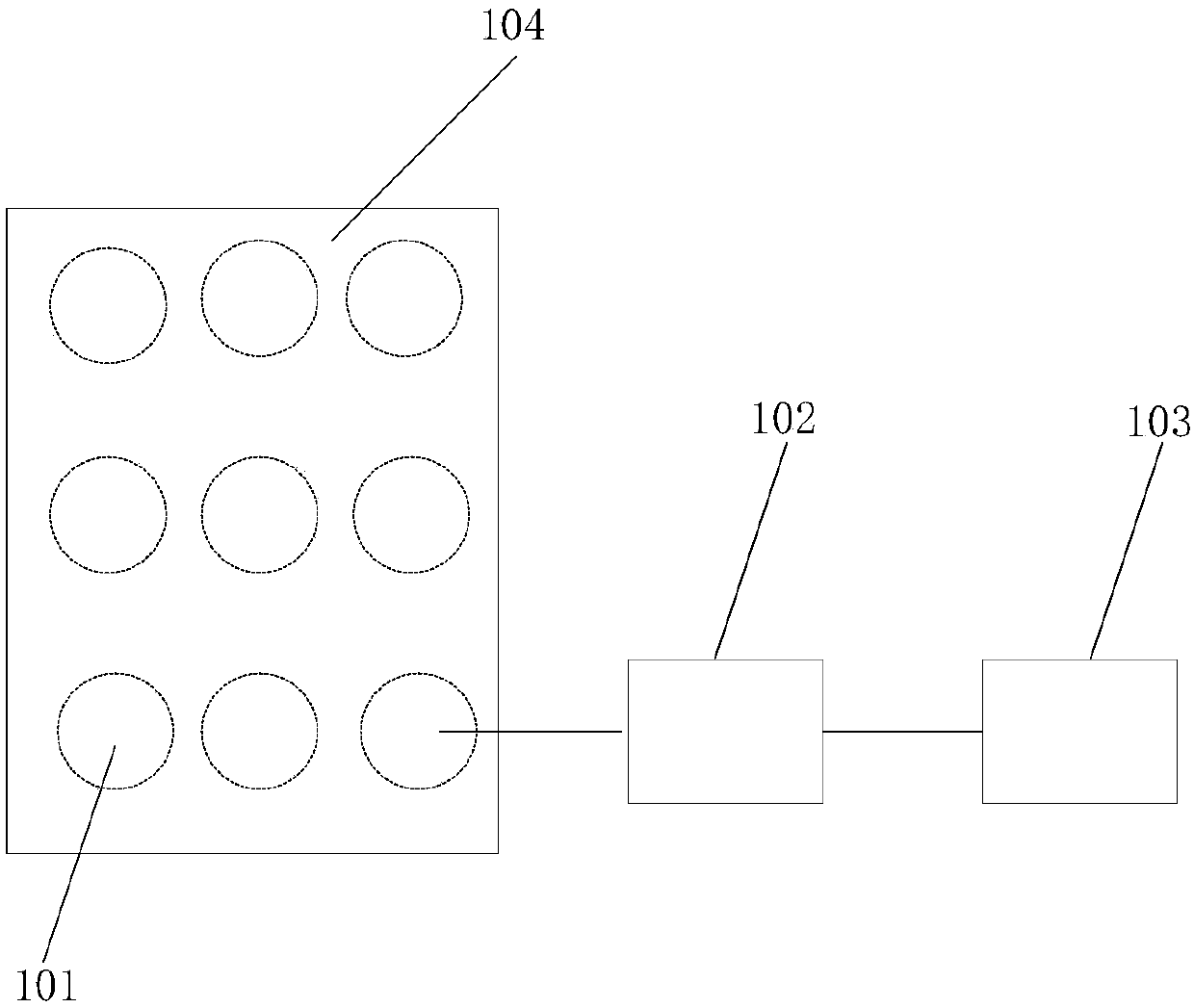

[0044] An embodiment of the present invention provides a voltage compensation device. The schematic diagram of the voltage compensation device is shown in figure 1 As shown, the voltage compensation device specifically includes the following components: a thermal sensor group 101 , a processor 102 and a power management module 103 .

[0045] Both the thermal sensor group 101 and the power management module 103 are electrically connected to the processor 102 .

[0046] The thermal sensor group 101 is disposed at a corresponding position of the pixel unit.

[0047] The processor 102 is configured to determine the actual pixel voltage of the pixel unit corresponding to the thermal sensor group 101 according to the temperature electrical signal when receiving the temperature electrical signal fed back by the thermal sensor group 101; The difference between the reference pixel voltages of the pixel unit determines the compensated data signal and sends it to the power management m...

Embodiment 2

[0053] Based on the same inventive concept, an embodiment of the present invention also provides a display device, the structural diagram of which is shown in figure 1 shown, including:

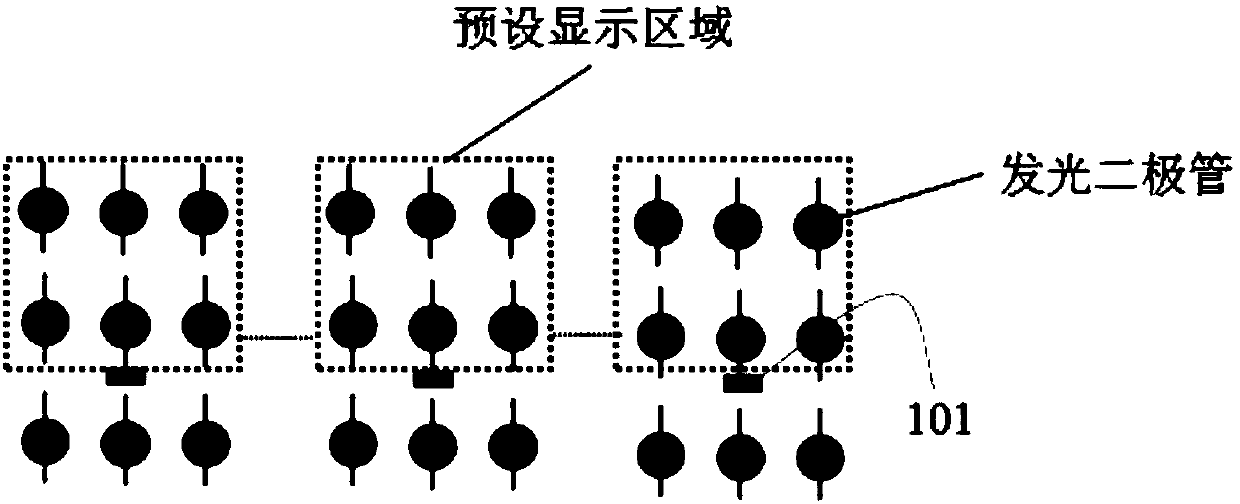

[0054] The display panel 104 includes any voltage compensation device as provided in the above-mentioned embodiments of the present invention. The pixel units in the display panel 104 include organic light emitting diodes (OLEDs), and the thermal sensor group 101 is disposed at corresponding positions of the organic light emitting diodes.

[0055] The beneficial effect obtained by using the display device provided by the embodiment of the present invention to perform the voltage compensation of the pixel unit is consistent with the aforementioned voltage compensation device provided by the embodiment of the present invention, which will not be repeated here.

[0056] In a specific implementation manner, the thermal sensor group in the embodiment of the present invention includes a plurality o...

Embodiment 3

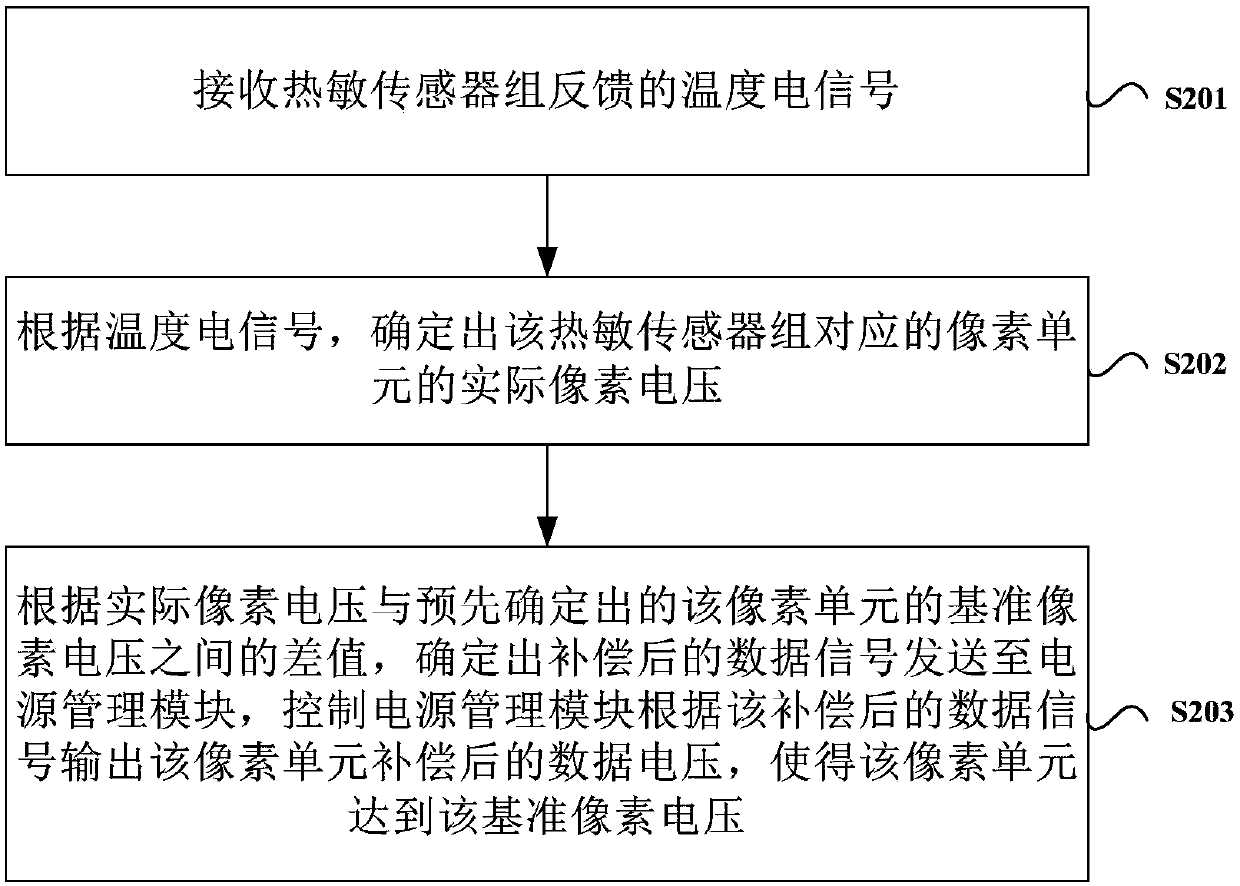

[0060] Based on the voltage compensation device or the display device provided by the above embodiments of the present invention, the embodiments of the present invention further provide a voltage compensation method. The specific flowchart of the voltage compensation method is as follows: image 3 As shown, it specifically includes the following steps:

[0061] S201: Receive a temperature electrical signal fed back by the thermal sensor group.

[0062] S202: Determine the actual pixel voltage of the pixel unit corresponding to the thermal sensor group according to the electrical temperature signal.

[0063] S203: According to the difference between the actual pixel voltage and the predetermined reference pixel voltage of the pixel unit, determine the compensated data signal and send it to the power management module, and control the power management module to output the The compensated data voltage of the pixel unit makes the pixel unit reach the reference pixel voltage.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com