One-stator two-rotor axial magnetic field motor stator and case mounting structure

An axial magnetic field, motor stator technology, applied in the magnetic circuit shape/pattern/structure, electromechanical device, magnetic circuit, etc., can solve the problems of difficult core manufacturing, increased mechanical loss, reduced efficiency, etc., to solve the problems of mechanical installation difficulties, Guarantee the effect of dimensional tolerance and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

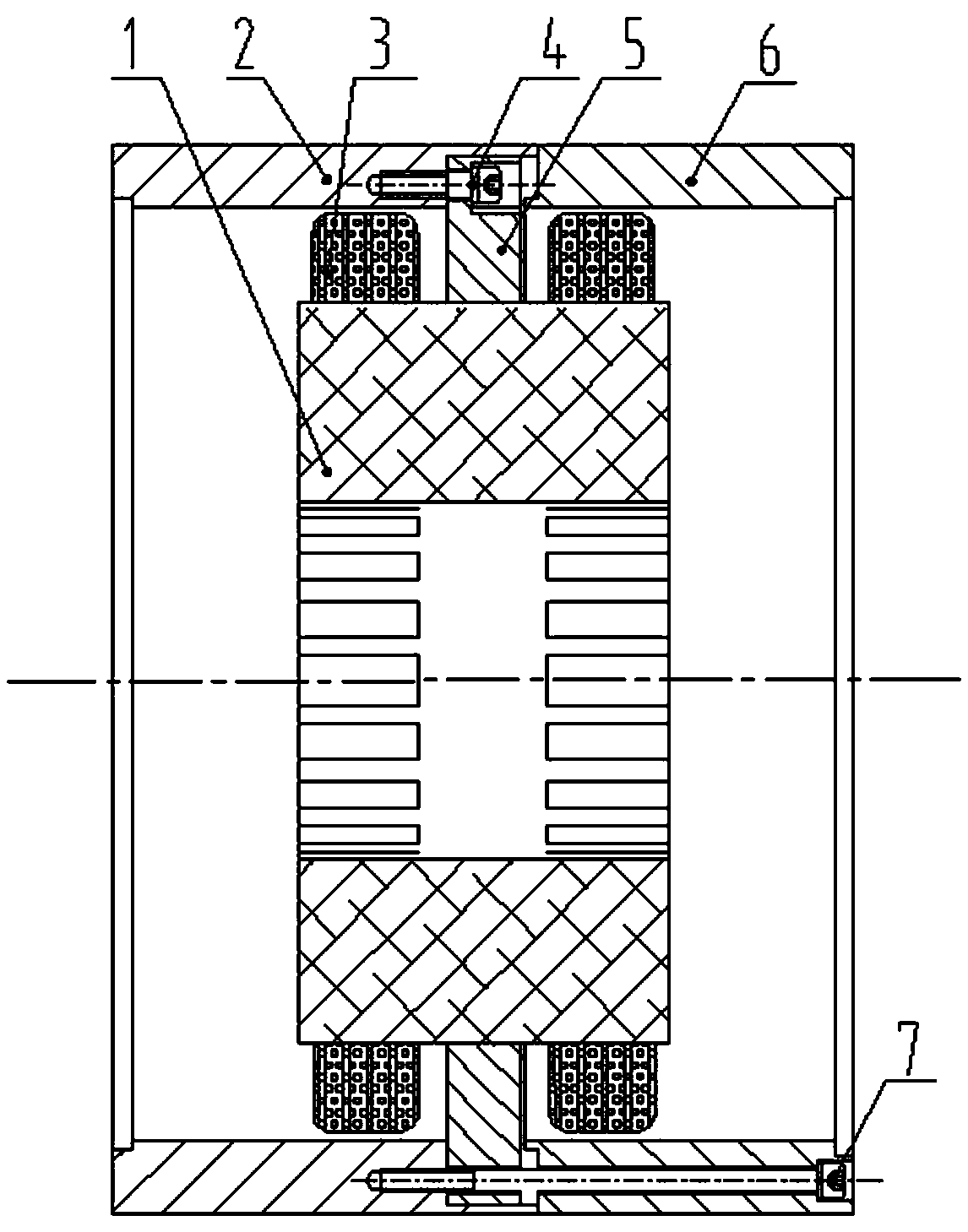

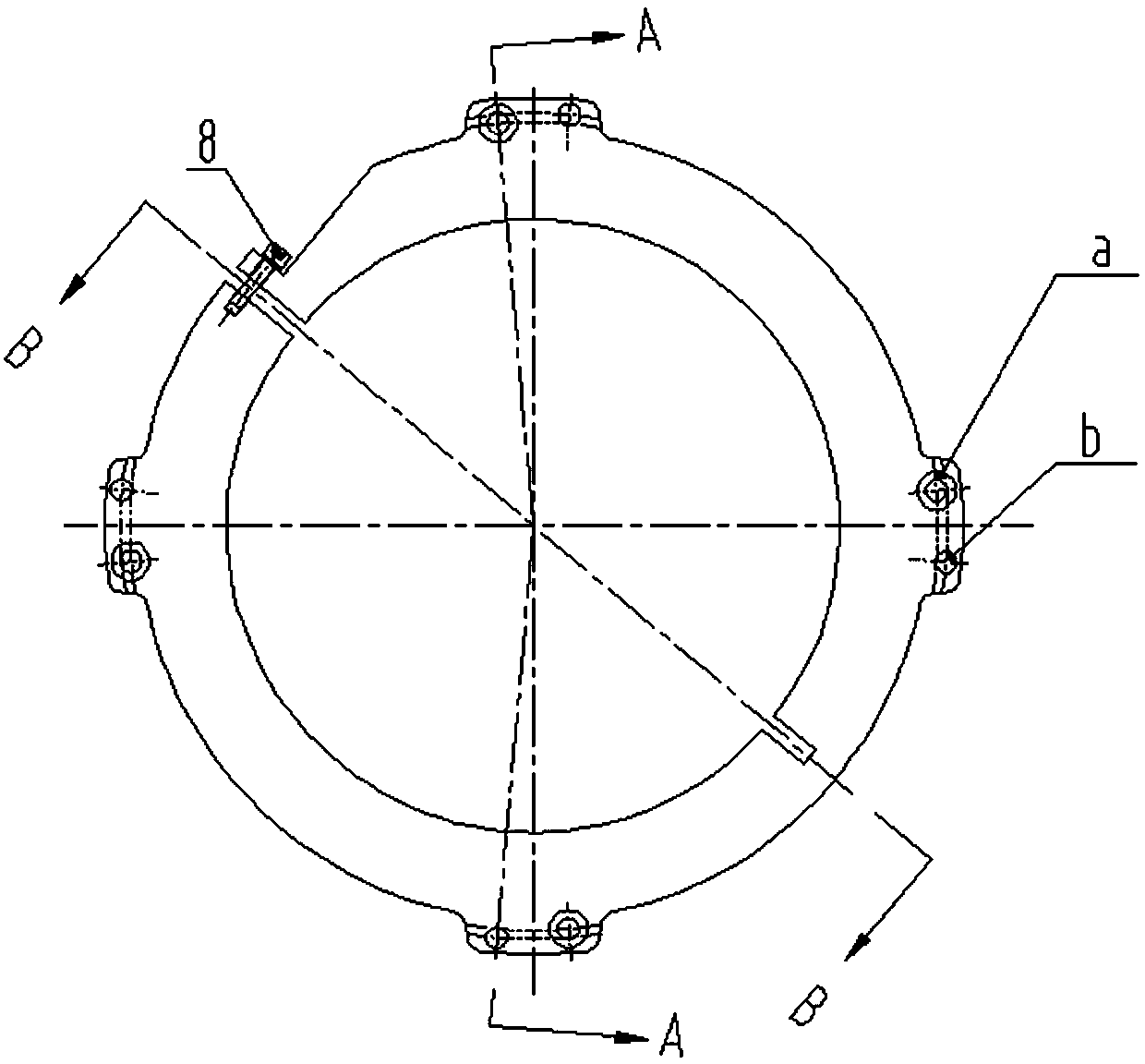

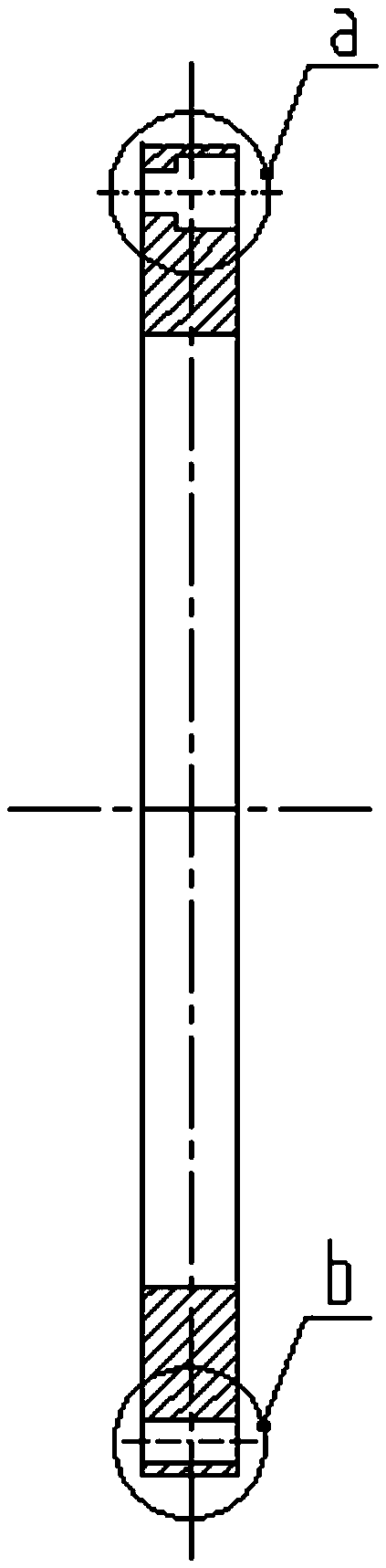

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, a single-stator double-rotor axial field motor stator and casing installation structure is composed of a slotted annular stator 1, a stator positioning ring 5, a left motor casing 2 and a motor right casing 6, and a slotted annular stator 1 The stator positioning ring 5 is installed in the middle of the motor left casing 2 and the motor right casing 6. There are slots on both sides of the slotted annular stator 1, and the copper wire winding 3 is placed, and the copper wire winding 3 is located in the stator positioning ring 5. on both sides.

[0035] The stator positioning ring 5 is a non-magnetic material, such as stainless steel, high-strength aluminum alloy, a circular ring with one side opening, the inner diameter of the stator positioning ring 5 is equal to the outer diameter of the grooved annular stator 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com