Field device for process automation

A process automation, field equipment technology, applied in the direction of electrical equipment shell/cabinet/drawer, circuit bendable/stretchable parts, printed circuit connected with non-printed electrical components, etc., can solve the material of compensation components Weakness, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

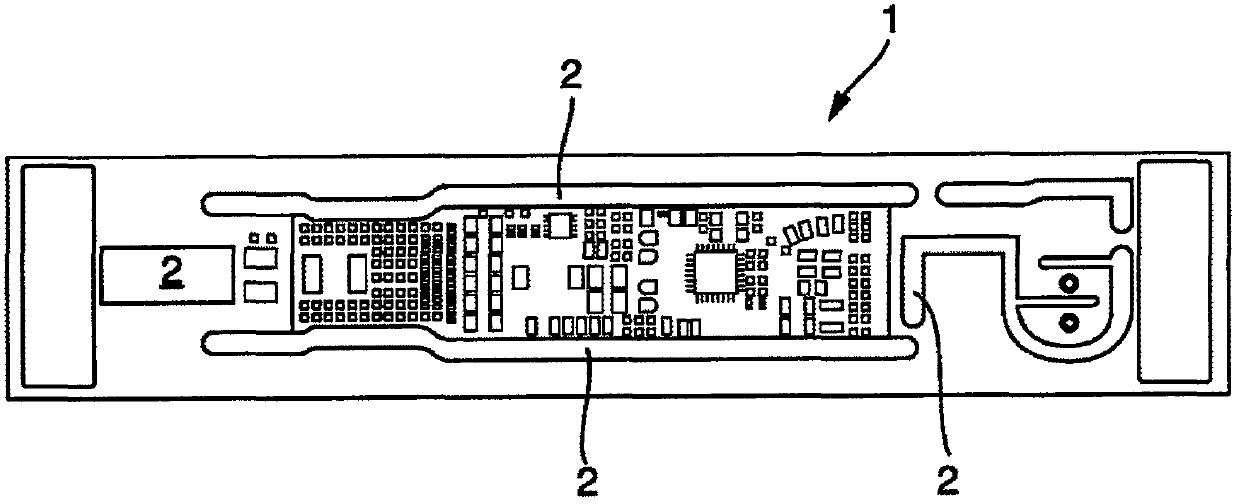

[0026] figure 1 A plan view of the printed circuit board 1 of an automated field device is shown.

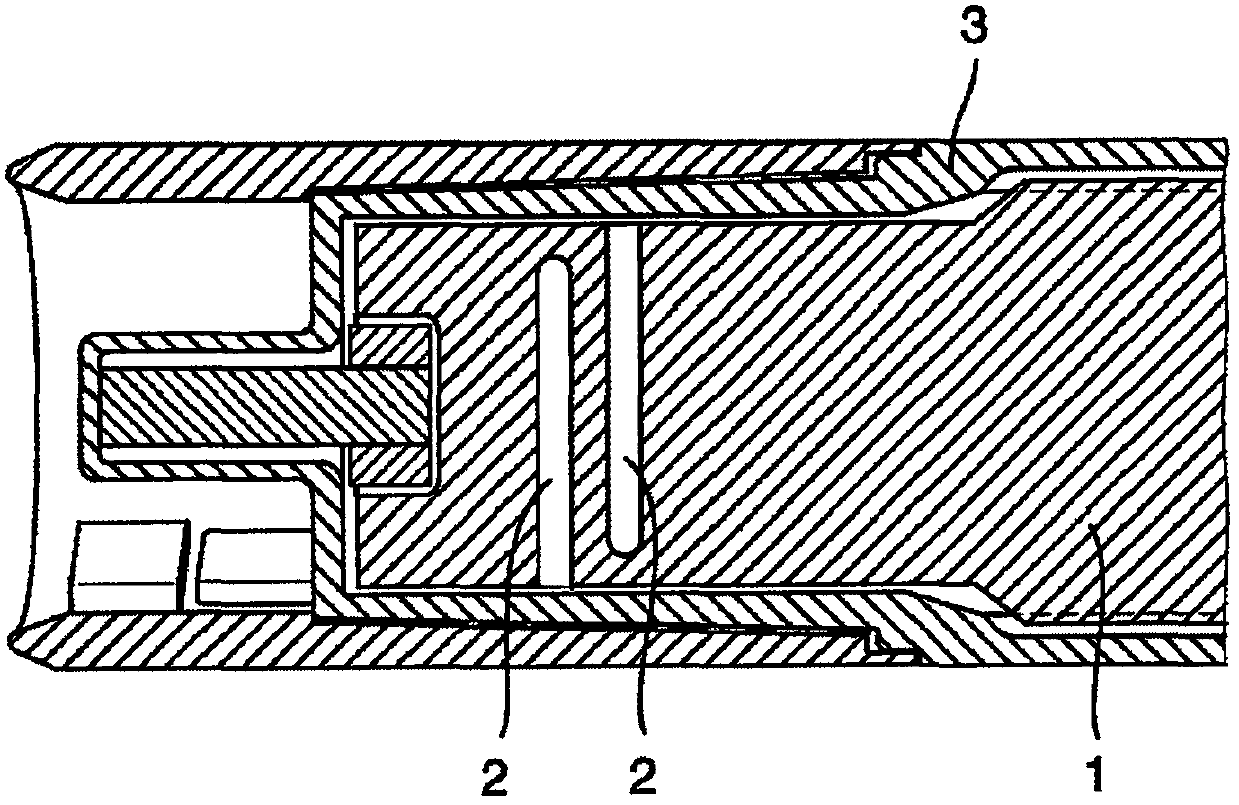

[0027] In the field of process automation, explosion-proof electronic device housings are often required. From a favorable point of view of thermal stress, it is difficult to attach the printed circuit board 1 to the housing 3 in the method required for explosion protection; the main method used for the design of an explosion-proof circuit in the prior art includes filling the housing 3 with a plastic infusion mixture. This makes it possible, for example, to safely electrically insulate energy storage stations containing enough energy to ignite an environment in which explosive gases or dust may be present. Conventionally, relevant explosion-proof standards require that the potting compound be bonded to the printed circuit board 1 and the housing 3.

[0028] The problem with attaching the printed circuit board 1 to the housing 3 and thermal stress is that, generally, the potting mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com