Caking fertilizer crushing device for agricultural industry

A crushing device and agricultural industry technology, applied in the agricultural field, can solve problems such as poor applicability, high equipment maintenance costs, and difficult maintenance, and achieve the effects of improving work efficiency and reducing labor intensity and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

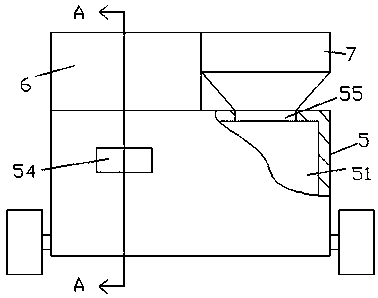

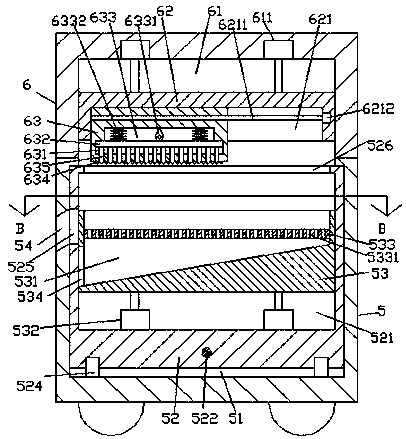

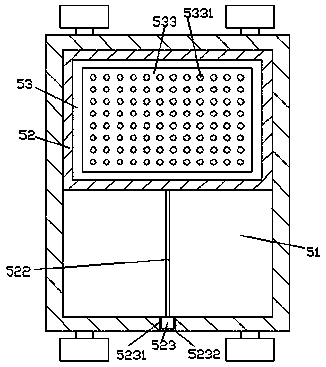

[0021] Such as Figure 1-Figure 7 As shown, a crushing device for agglomerated fertilizer used in agricultural industry of the present invention includes a movable body 5, a crushing box 6 installed on the left top end of the body 5, and a hopper 7 on the right top end. The body 5 is provided with a first cavity 51 extending left and right, and the crushing box 6 is provided with a second cavity 61 whose bottom communicates with the top of the first cavity 51 below the crushing box 6 , the top of the first cavity 51 below the hopper 7 is penetrated with a feed inlet 55 connected to the bottom of the hopper 7, and the first cavity 51 is slidingly fitted and connected with a sliding frame 52, the bottom of the sliding frame 52 is provided with a rolling wheel 524, the sliding frame 52 is provided with a third cavity 521, the third cavity 521 is slidingly connected with a lifting charging frame 53, the lifting The third cavity 521 at the bottom of the charging rack 53 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com