Electrostatic eliminating and cleaning device for carrier band

A cleaning device, a technology for removing static electricity, applied in the directions of static electricity, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of no static electricity and cleanliness control, etc., and achieve the effect of eliminating static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

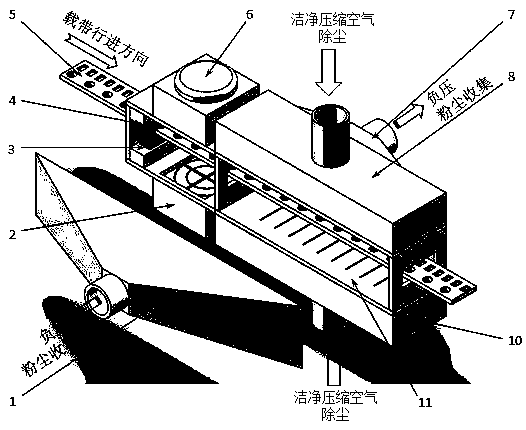

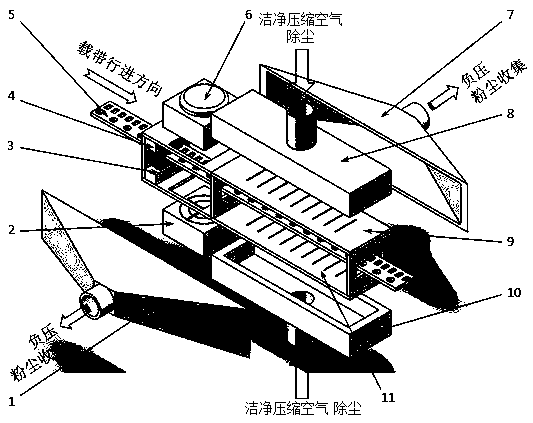

[0015] Under the traction of the winding mechanism, the carrier tape enters the static removal cleaning device from the left side, first enters the static removal room, passes through the brush (3) (4), and under the action of the brush (3) (4), Dust and foreign objects with certain adhesion on the surface of the carrier tape are brushed up, fall off or lightly attached to the surface of the carrier tape, and then pass through the ion wind area. The air is blown to the upper and lower surfaces of the carrier tape to neutralize the electrostatic charges generated by the friction between the surface of the carrier tape and the brush during processing and before. Then enter the dust removal clean room, the static electricity removal room and the dust removal clean room are separated by a partition, the high-speed and high-pressure clean compressed air passes through the compressed air outlets (8) (10) arranged up and down, and sprays through the narrow and long nozzles (9) (11). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com