Y-zeolite containing structured ultra-large micropores, and preparation method and application thereof

A microporous, ultra-large technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., which can solve the problems of poor matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

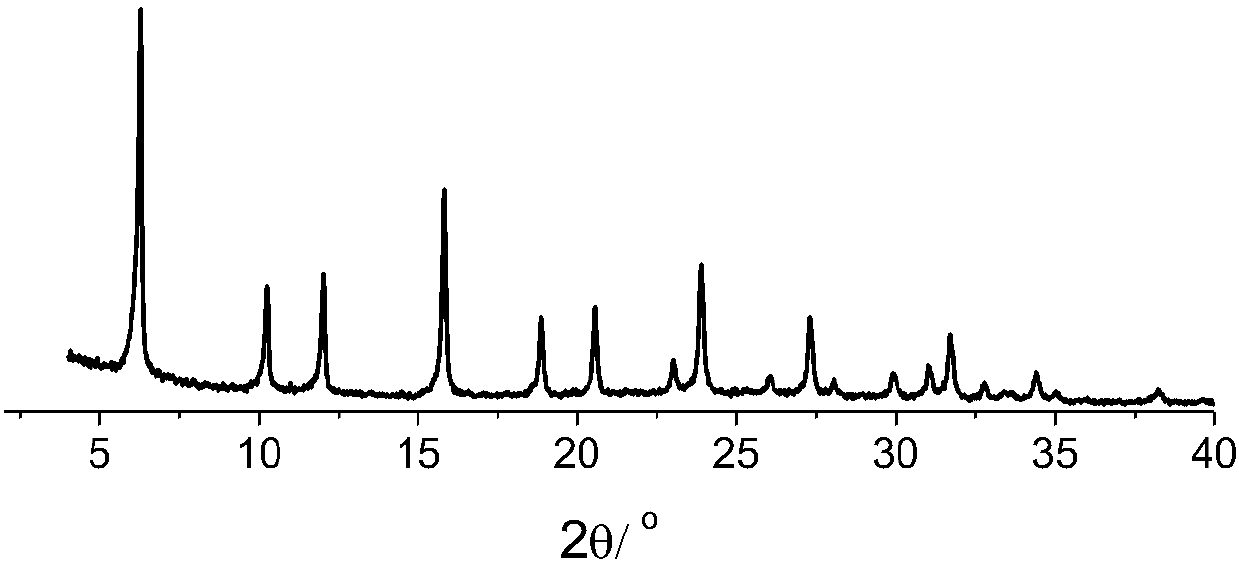

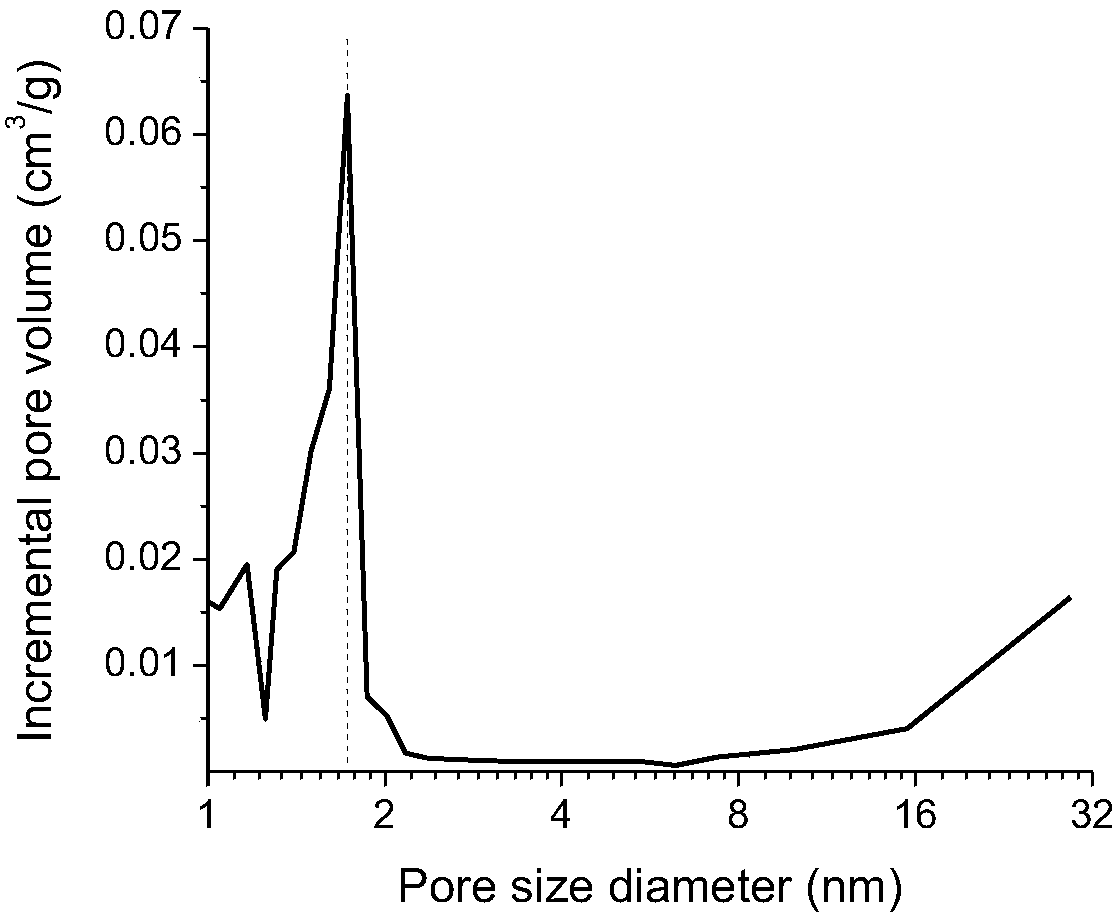

[0037] Y zeolite powder was purchased from the market. XRD characterization showed that it had typical FAU zeolite structure characteristics, unit cell parameter 2.460nm; total specific surface area obtained from nitrogen adsorption characterization was 644m 2 / g, the total pore volume is 0.35ml / g, and the pore size in the range of 1-2nm has no contribution from pore volume and specific surface area.

[0038] Take 50g Y zeolite powder, add it to 500ml deionized water, add 10g acetic acid, 5g phosphoric acid and 12g ammonium chloride respectively, treat at 60°C for 4h, filter after cooling, wash and dry to obtain 42g zeolite powder. Add this zeolite to 210g of deionized water, add 25ml of concentrated ammonia water, then dissolve 21g of hexadecyltrimethylammonium bromide, stir at room temperature for 2 hours, then transfer to a self-pressure crystallization kettle, and crystallize at 150°C. After cooling for 48 hours, filter, wash, dry, and roast at 550°C, the Y zeolite contain...

Embodiment 2

[0041] Take 50g Y zeolite powder, add it to 500ml deionized water, add 4.5g oxalic acid, 6.5g hydrochloric acid and 15g ammonium nitrate respectively, treat at 95°C for 2h, filter after cooling, wash and dry to obtain 40g zeolite powder. Add this zeolite to 200g of deionized water, add 2.8g of sodium hydroxide, then dissolve 21g of hexadecyltrimethylammonium chloride, stir at room temperature for 2 hours, then transfer to a self-pressurized crystallization kettle. Crystallize for 48 hours, cool, filter, wash, dry, and bake at 580°C to obtain the Y zeolite with regular ultra-large micropores.

[0042] XRD characterization shows that it has typical FAU zeolite structure characteristics, the unit cell parameter is 2.441nm; the total specific surface area obtained by nitrogen adsorption characterization is 780m 2 / g, the total pore volume is 0.52ml / g. The silicon-aluminum molecular ratio is 37.5. Calculated by the BJH method, it contains ultra-large micropores larger than 1 nano...

Embodiment 3

[0044] Take 50g Y zeolite powder, add it to 500ml deionized water, add 6.8g citric acid, 3.5g sulfuric acid and 17g ammonium sulfate respectively, treat at 90°C for 8h, filter after cooling, wash and dry to obtain 42g zeolite powder. Add this zeolite to 210g of deionized water, add 3.5g of potassium hydroxide, then dissolve 18g of n-dodecylamine and 20ml of ethanol, stir at room temperature for 2 hours, then transfer to a self-pressure crystallization kettle, and crystallize at 160°C After cooling for 20 hours, filter, wash, dry, and roast at 550°C, the Y zeolite with regular ultra-large micropores is obtained.

[0045] XRD characterization shows that it has typical FAU zeolite structure characteristics, the unit cell parameter is 2.433nm; the total specific surface area obtained by nitrogen adsorption characterization is 685m 2 / g, the total pore volume is 0.43ml / g. The silicon-aluminum molecular ratio is 6.8. Calculated by the BJH method, it contains ultra-large micropores...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com