Recycling device and method for low-grade waste heat of thermal power plant

A low-grade, thermal power plant technology, applied in the direction of preheating, feed water heaters, heat exchangers, etc., can solve the problem of 1.5-2.5% increase in steam consumption of the unit, and achieve the effect of improving heat dissipation, increasing thermal efficiency, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

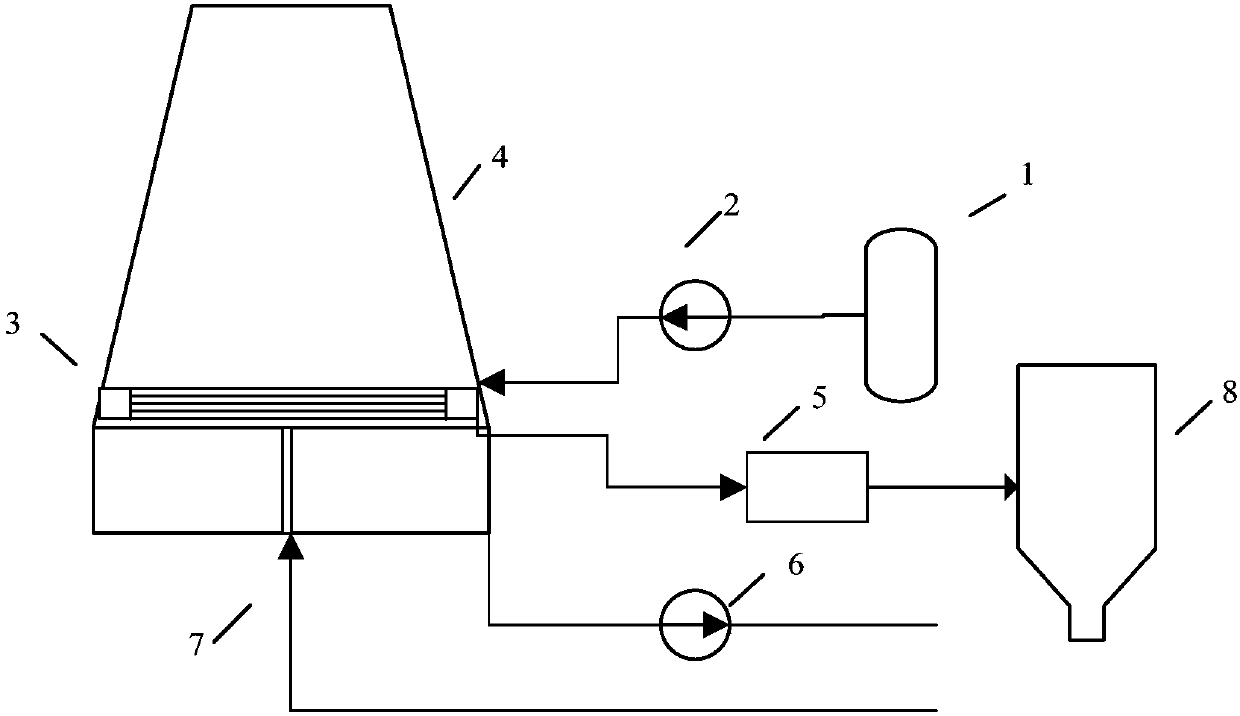

[0024] A device for recycling low-grade waste heat in a thermal power plant, comprising a cooling tower 4 and a circulating water pump 6 connected to the cooling tower 4, and a heat exchanger 3 is arranged inside the water tank of the cooling tower 4 (the heat exchange tube is a finned tube, and the specification is Countercurrent arrangement), the heat exchanger 3 is provided with a desalted water inlet, a desalted water outlet, a circulating water inlet pipe 7 and a circulating water outlet, the desalted water inlet is connected to the desalted water tank 1 through the desalted water pump 2, and the desalted water outlet is connected to the desalted water tank 1 through the deoxygenated Device 5 is connected with boiler 8.

[0025] The process of reusing the low-grade waste heat of thermal power plants using the above-mentioned device is as follows: desalted water (flow rate: 200t / h, initial temperature: 20°C) is pumped from desalted water tank 1 to heat exchanger 3, and thr...

Embodiment 2

[0028] A device for recycling low-grade waste heat in a thermal power plant, comprising a cooling tower 4 and a circulating water pump 6 connected to the cooling tower 4, and a heat exchanger 3 is arranged inside the water tank of the cooling tower 4 (the heat exchange tube is a finned tube, and the specification is Countercurrent arrangement), the heat exchanger 3 is provided with a desalted water inlet, a desalted water outlet, a circulating water inlet pipe 7 and a circulating water outlet, the desalted water inlet is connected to the desalted water tank 1 through the desalted water pump 2, and the desalted water outlet is connected to the desalted water tank 1 through the deoxygenated Device 5 is connected with boiler 8.

[0029] The process of using the above device to reuse low-grade waste heat in thermal power plants is as follows: desalted water (flow rate: 210t / h, initial temperature: 22°C) is sent to heat exchanger 3 through desalted water tank 1 by desalted water pu...

Embodiment 3

[0032] A device for recycling low-grade waste heat in a thermal power plant, comprising a cooling tower 4 and a circulating water pump 6 connected to the cooling tower 4, and a heat exchanger 3 is arranged inside the water tank of the cooling tower 4 (the heat exchange tube is a finned tube, and the specification is Countercurrent arrangement), the heat exchanger 3 is provided with a desalted water inlet, a desalted water outlet, a circulating water inlet pipe 7 and a circulating water outlet, the desalted water inlet is connected to the desalted water tank 1 through the desalted water pump 2, and the desalted water outlet is connected to the desalted water tank 1 through the deoxygenated Device 5 is connected with boiler 8.

[0033] The process of reusing the low-grade waste heat of thermal power plants using the above-mentioned device is as follows: desalted water (flow rate is 220t / h, initial temperature is 25°C) is sent to heat exchanger 3 through desalted water tank 1 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com