Repair method of carbon roasting furnace kiln

A carbon roasting furnace and repair method technology, applied in the roasting furnace and carbon production field, can solve the problems of affecting product quality, large temperature difference between upper and lower furnaces, and short service cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

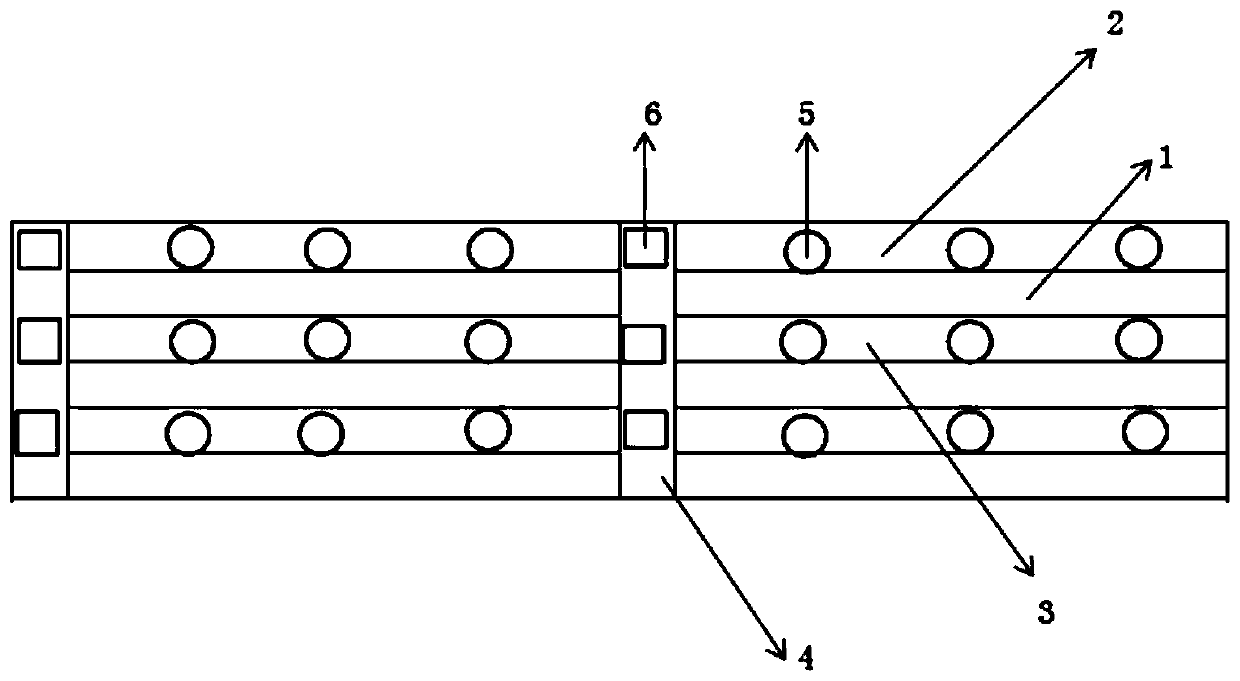

Image

Examples

Embodiment Construction

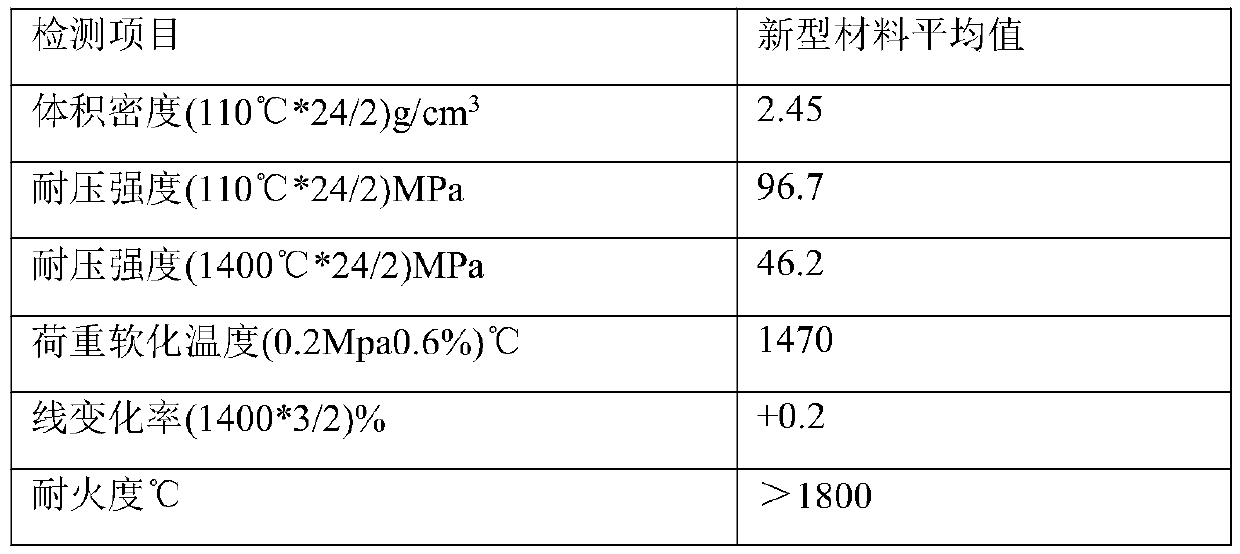

[0126] Spray paint technical indicators:

[0127] Test items

new material average

Bulk density (110℃*24 / 2) g / cm 3

2.45

Compressive strength (110℃*24 / 2) MPa

96.7

Compressive strength (1400℃*24 / 2) MPa

46.2

Softening temperature under load (0.2Mpa0.6%)℃

1470

[0128] Line rate of change (1400*3 / 2)%

+0.2

Refractoriness °C

>1800

High temperature flexural strength (1300℃*1 / 2) MPa

1.2

Seismic stability (1100℃*water cooling) / time

≥50

AL203%

69.76

Thermal conductivity (surface temperature 1100°C) W / M.K

1.130

[0129] Introduction to field work:

[0130] 1. Preparatory work before construction

[0131] 1.1 Prepare all construction machinery and tools;

[0132] 1.2 Prepare safety helmets, safety belts, gloves, protective clothing and other labor protection supplies;

[0133] 1. Prepare hard pressing materials to avoid affecting on-site use;

[0134] 1.4 Check...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com