Programmable capacitive circuit

A capacitor circuit, capacitor technology, applied in program control, instrument, computer control, etc., can solve the problems of not being able to simulate the whole process, and the range of adjusting the capacitance value is limited, so as to achieve the effect of stable capacitance value and wide adjustable range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

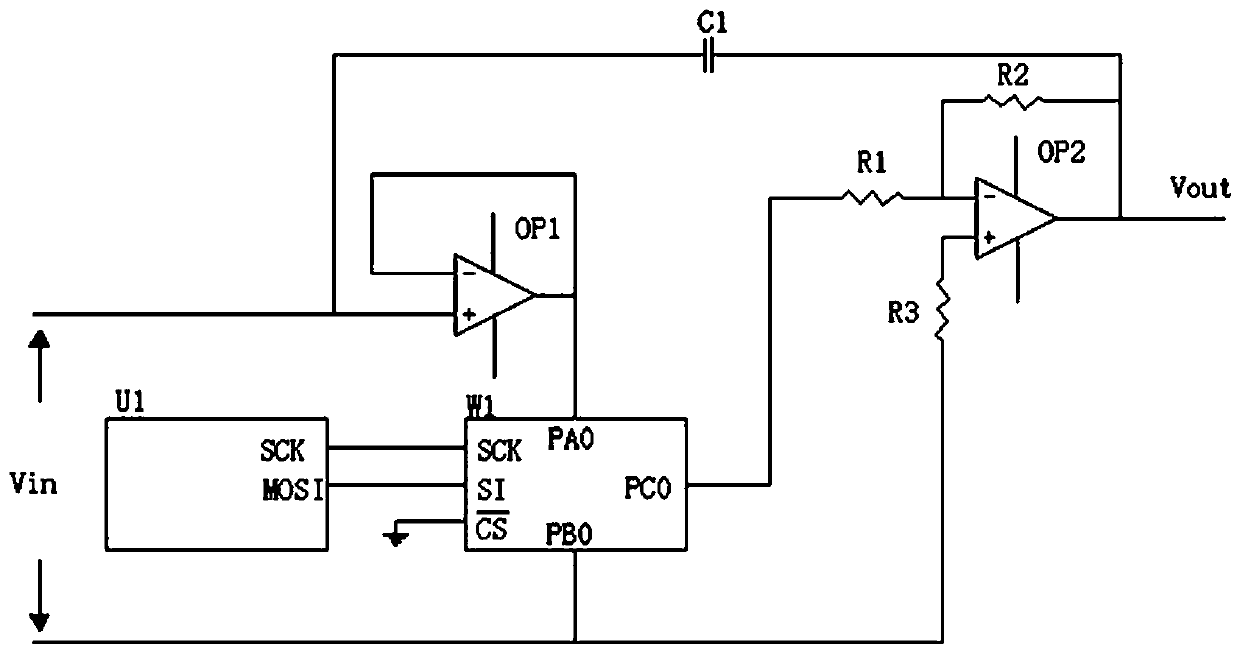

[0026] Attached figure 1 As shown, a programmable capacitor circuit includes a signal input terminal, a signal output terminal, and a first operational amplifier OP1 for voltage following and a second operational amplifier OP2 for voltage amplification connected to the signal input terminal. A digital potentiometer W1 is connected between the first operational amplifier OP1 and the second operational amplifier OP2, the digital potentiometer W1 is connected to a control chip (U1), and the signal input terminal is connected to the first operational amplifier OP1. The node is connected to the first end of the capacitor C1, and the second end of the capacitor C1 is connected to the signal output end and the output end of the second operational amplifier OP2.

[0027] working principle:

[0028] The signal Vin is input from the signal input terminal, and after the first operational amplifier OP1, the voltage follows the output, and then is divided by the digital potentiometer W1 and th...

Embodiment 2

[0030] On the basis of Example 1, combined with figure 1 As shown, the inverting input terminal of the first operational amplifier OP1 is connected to the output terminal of the first operational amplifier OP1, and the same direction input terminal of the first operational amplifier OP1 is connected to the first terminal of the signal input terminal and the capacitor C1 The output terminal of the first operational amplifier OP1 is connected to the digital potentiometer W1.

[0031] working principle:

[0032] The purpose of the voltage follower circuit composed of the first operational amplifier OP1 is to reduce signal loss and enhance the driving ability of the signal to the subsequent stage.

[0033] Further, the same direction input terminal of the second operational amplifier OP2 is connected in series with a resistor R3 and then connected to the second terminal of the signal input terminal, and the inverting input terminal of the second operational amplifier OP2 is connected in...

Embodiment 3

[0037] On the basis of Example 2, combined with figure 1 As shown, the fixed terminal of the digital potentiometer W1 is respectively connected to the output terminal of the first operational amplifier OP1 and the second terminal of the signal input terminal, and the second terminal of the signal input terminal is connected in series with the resistor R3. It is connected to the same direction input terminal of the second operational amplifier OP2, and the control pin of the digital potentiometer W1 is connected to the control chip (U1).

[0038] working principle:

[0039] In this connection mode, the adjustable end of the digital potentiometer W1 is connected to

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com