High-temperature vacuum water-bath dust remover

A high-temperature vacuum and dust collector technology, applied in chemical instruments and methods, dispersed particle separation, and use of liquid separators, etc., can solve the problems of incomplete dust removal and excessive exhaust emissions, and achieve simple structure, odor reduction, installation and use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

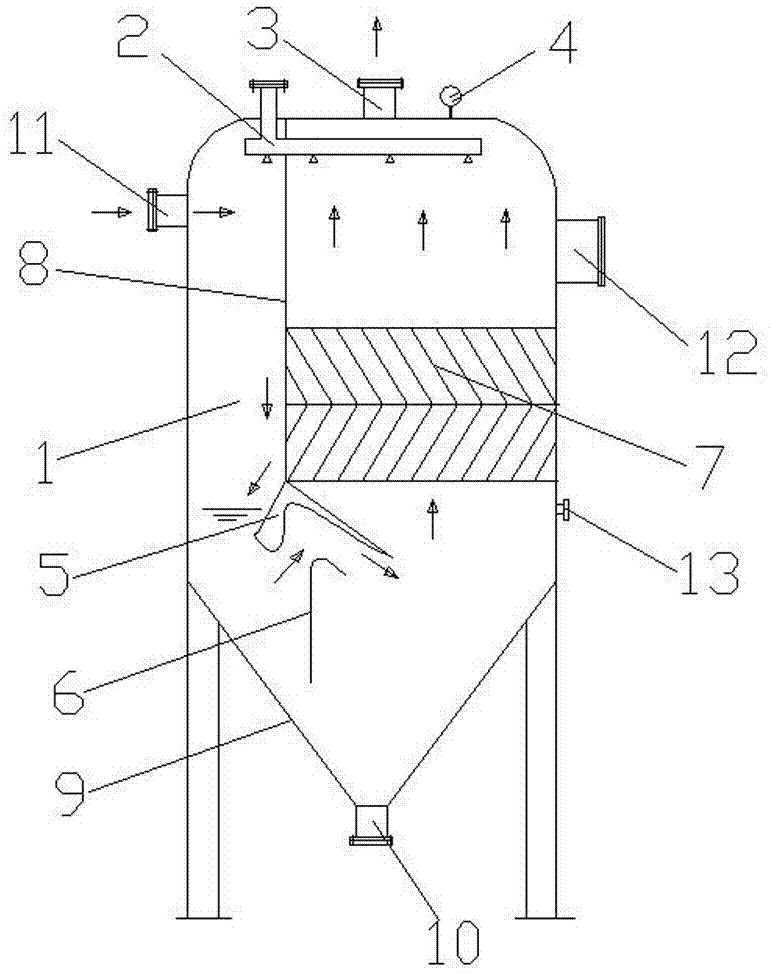

[0011] Embodiment: A high-temperature vacuum water bath deduster, comprising a dust removal tank 1; the upper part of the dust removal tank 1 is provided with a spray flushing water replenisher 2, an exhaust port 3, and a vacuum meter 4, and the inside of the dust removal tank 1 is provided with a L Shaped cutoff 5, barb-shaped cutoff 6, water collector 7; the inner side of the L-shaped cutoff 5 is provided with an S-shaped cutoff surface, and the L-shaped cutoff 5 is inclined and inverted, and the barb-shaped The cutoff plate 6 is arranged below the S-shaped cutoff surface of the L-shaped flow cutoff plate 5, and an air intake baffle 8 and a water collector 7 are arranged above the L-shaped flow cutoff plate 5; There is a conical reaction pool 9, and the bottom of the conical reaction pool 9 is provided with a sewage outlet 10.

[0012] The inclination and inversion angle of the L-shaped cutoff plate 5 is determined according to the size of the dust removal tank 1, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com