Spraying device and spraying method applied to energy-saving paint on furnace inner wall

A spraying device and energy-saving coating technology, applied in the direction of surface coating liquid device, spraying device, liquid spraying device, etc., can solve the problems of complex spraying device, many parts, complex structure, etc., and achieve high construction efficiency and coating Uniform, smooth coating surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

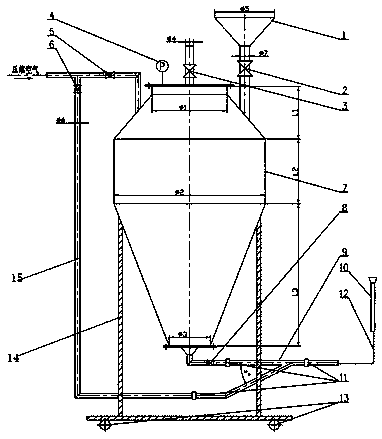

[0025] Embodiment 1: see figure 1 , a spraying device applied to the energy-saving paint on the inner wall of the furnace, the spraying device includes a material tank body 7, a feed hopper 1, a bracket 14 and a pipeline connected to the material tank body, wherein the material tank body is arranged on the bracket 14, A feed hopper 1 is provided on the upper side of the tank body, and a Y-shaped connector is provided below the tank body. One end of the Y-shaped connector is connected to the bottom of the tank body, and the other end is connected to a compressed air pipeline. The tank body A pressure gauge 4 and a tank exhaust ball valve 3 are also arranged above; a feed hopper ball valve 2 is arranged on the pipeline between the feed hopper 1 and the tank body 7; an exhaust pipe is arranged above the tank body , the exhaust pipe is provided with a material tank exhaust ball valve 3; one side of the material tank body is provided with a compressed air inlet pipe, and the air i...

Embodiment 2

[0029] Example 2: see figure 1 , a spraying method applied to a spraying device for energy-saving paint on the inner wall of a furnace. The method is as follows: 1) The working pressure of the compressed air is adjusted according to the volume density of the paint, so that the paint is sprayed out and the kinetic energy overcomes the pipeline. The resistance, and the pressure of the compressed air drainage match the spraying pressure of the paint nozzle; under the condition that the effective volume of the material tank and the length of the rubber hose to be sprayed are fixed, according to the density of the energy-saving paint, the required compressed air pressure is calculated; For example, the effective volume of the tank is 0.25 meters 3 , When the length of the spraying rubber hose is 20 meters, adjust the working pressure of the compressed air as shown in the table below:

[0030] Coating bulk density (ton / m 3 )

Compressed air working pressure (Mpa) R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com