A Swing Type Half Body Spool Plug Valve

A swing-type, half-body technology, applied in valve details, valve devices, multi-port valves, etc., can solve the problems that the valve cannot be opened and closed quickly, and the valve is easy to block, so as to facilitate automatic operation, improve throughput, and structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

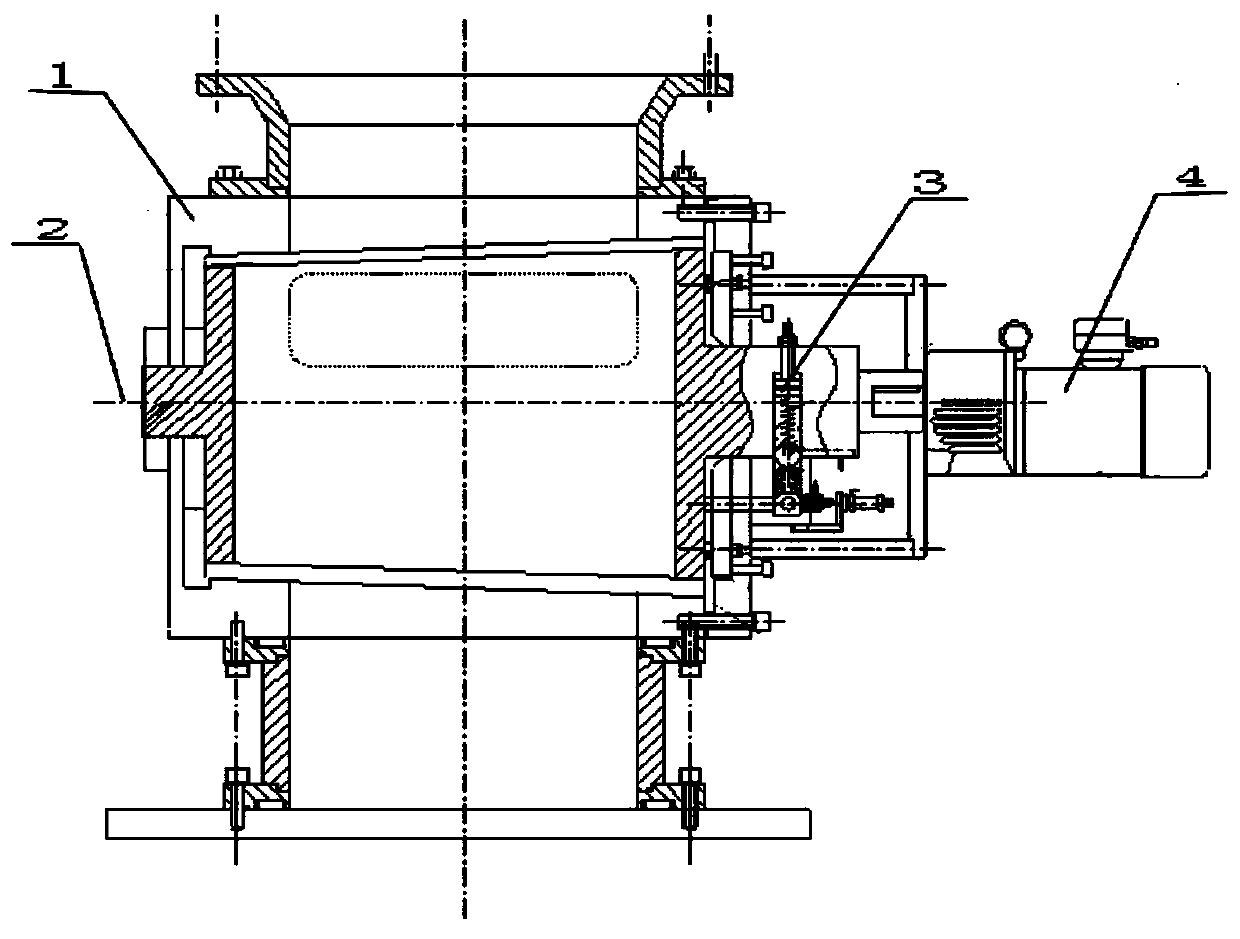

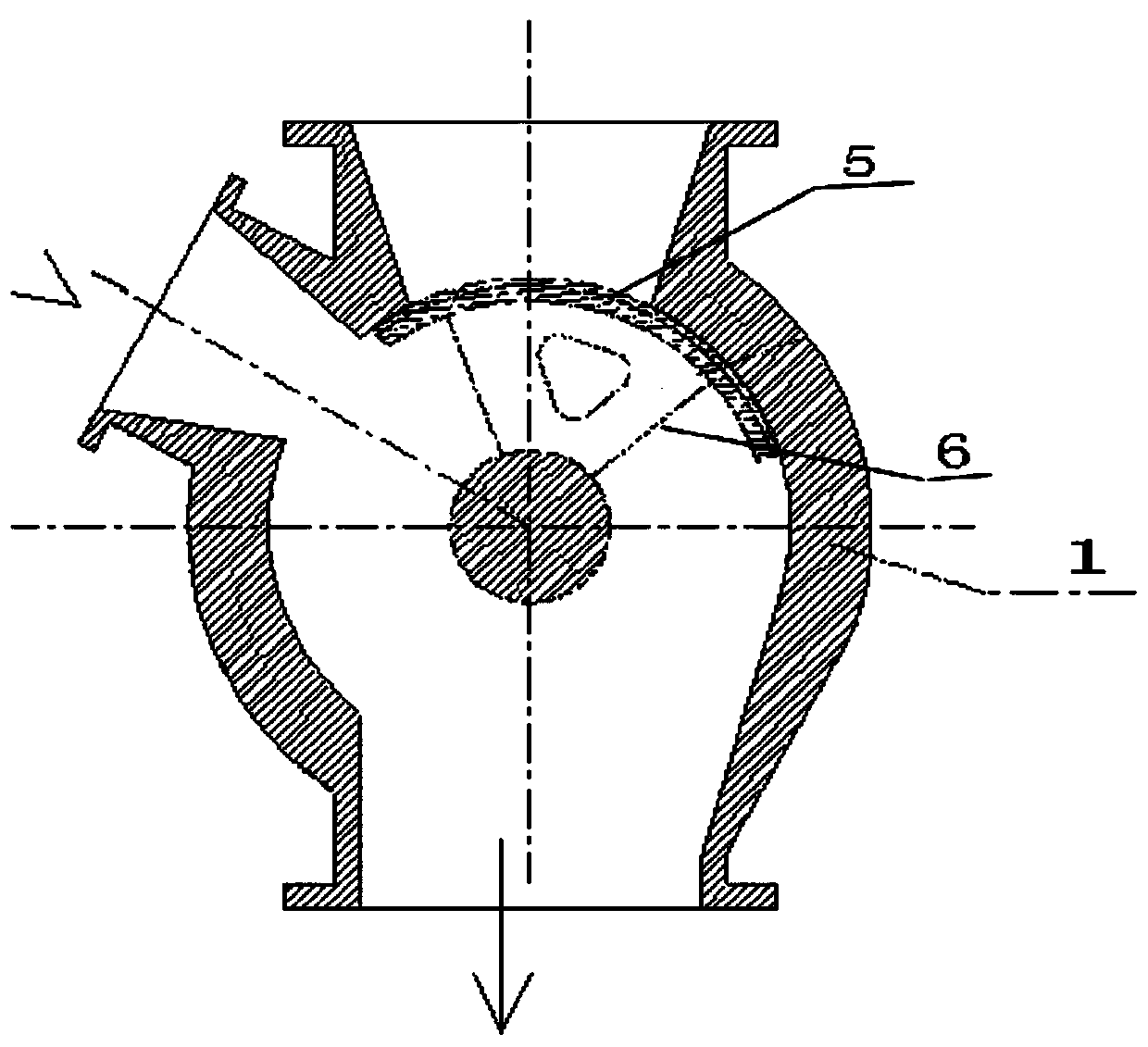

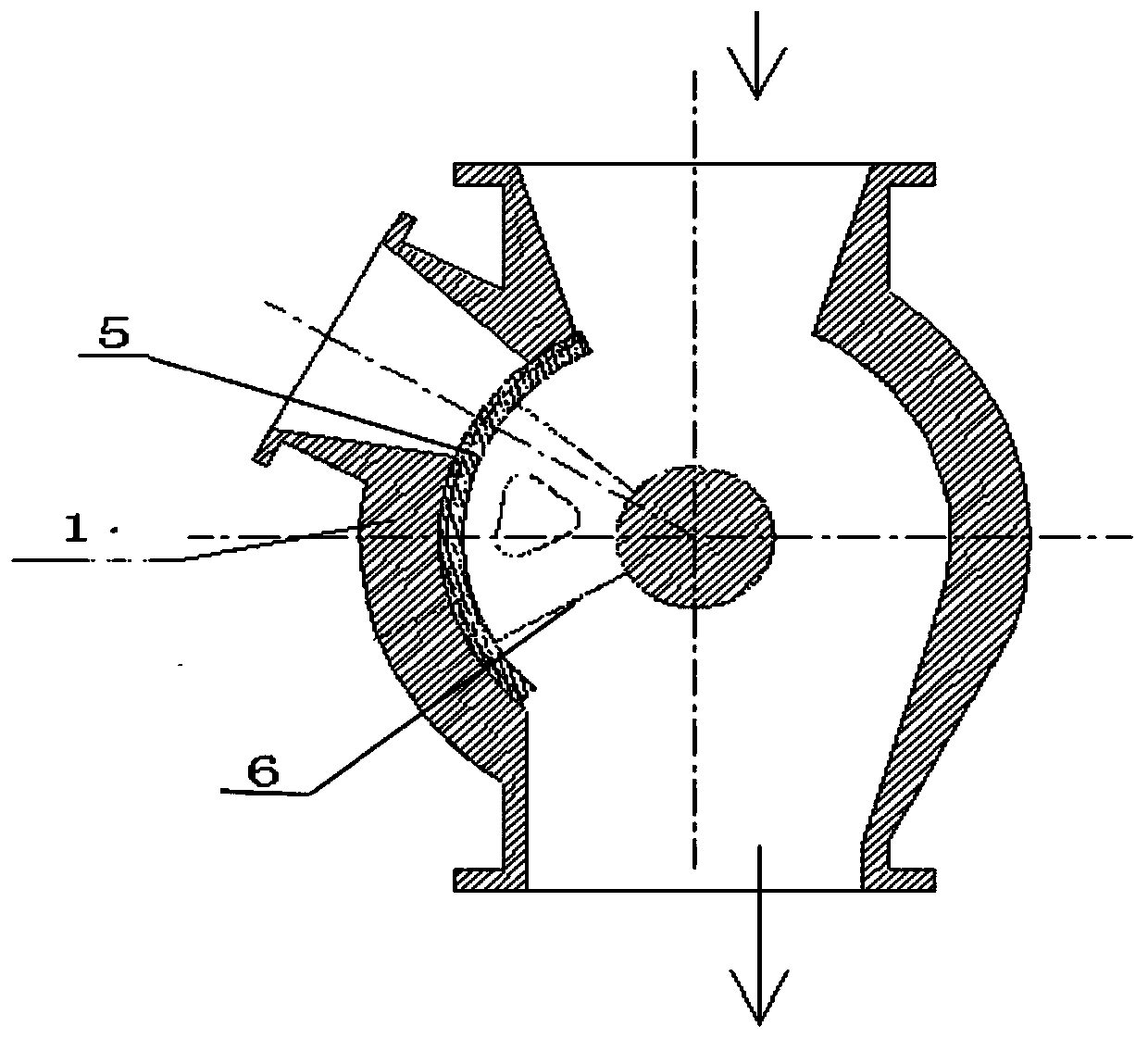

[0027] see Figure 1-5 , a swing-type half-body spool plug valve, including a valve body 1, the valve body 1 includes a half-body swing cock and a power swing mechanism 4, and the half-body swing cock is mounted on the valve body 1 through a rotating shaft 2 , and connected to the power output end of the power swing mechanism 4 through the rotating shaft 2, the half-body mating surface of the half-body swinging cock and the opening and closing mating surface of the valve body 1 are slidably matched to realize the opening and closing of the valve; Described valve is also provided with safety self-locking mechanism 3, and described safety self-locking mechanism 3 comprises fixed vertical cylinder body, and described fixed vertical cylinder body is arranged on rotating shaft end 7, and described rotating shaft end 7 is provided with A pin hole, a push pin and a spring are arranged below the pin hole, the push pin and the pin hole are slidably connected, a piston 10 and a ball 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com