Metal 3D printing method

A 3D printing and metal technology, applied in the field of 3D printing, can solve the problems of high price, low molding efficiency, slow SLM printing speed, etc., and achieve low production cost and post-maintenance cost, simple and compact overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

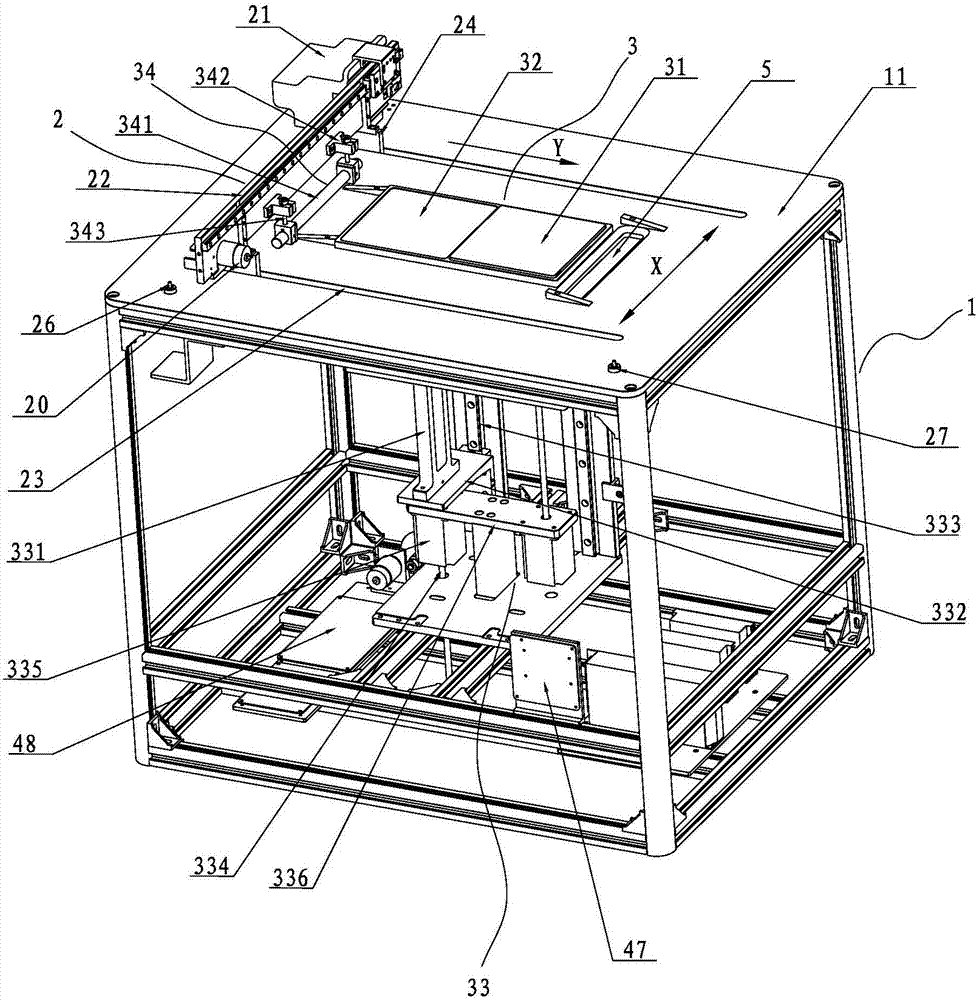

[0035] The metal 3D printing method described in this embodiment is based on a metal 3D printing device, such as figure 1 as shown,

[0036] The metal 3D printing device includes a base 1 , and a nozzle mechanism 2 , a molding mechanism 3 and a control unit 4 arranged on the base 1 .

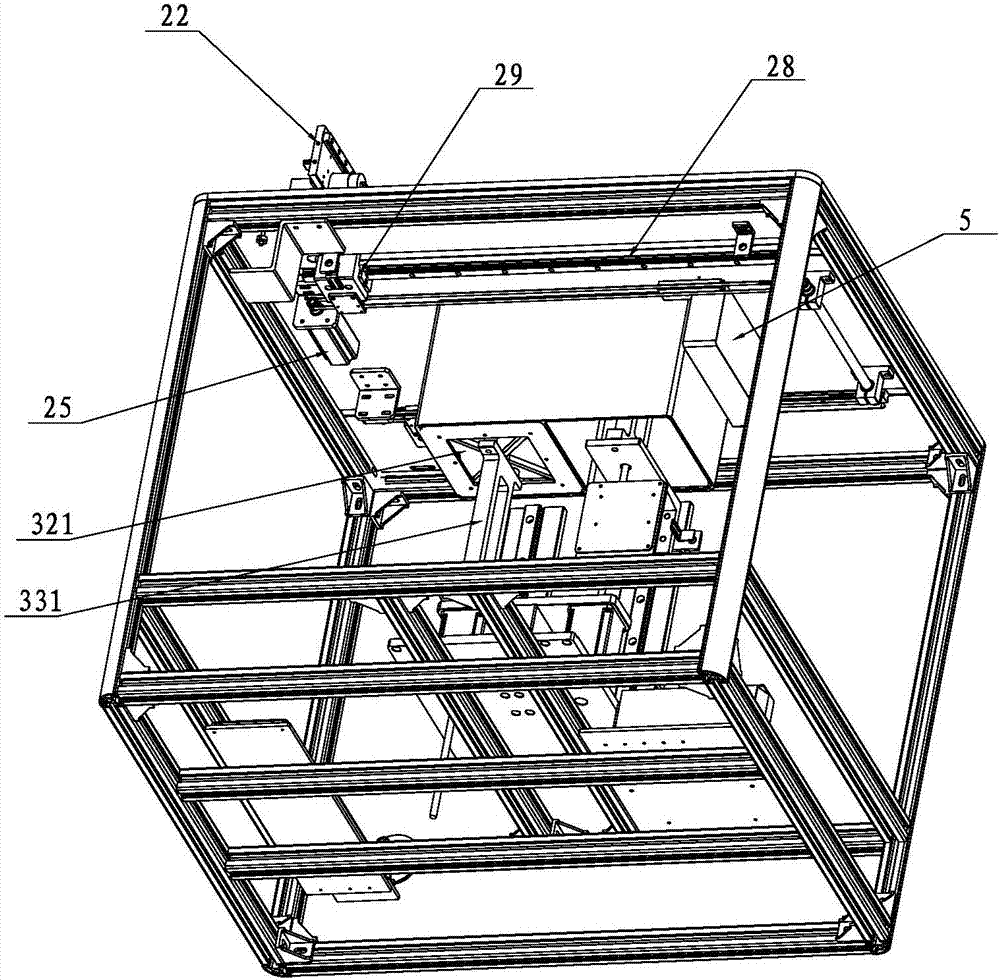

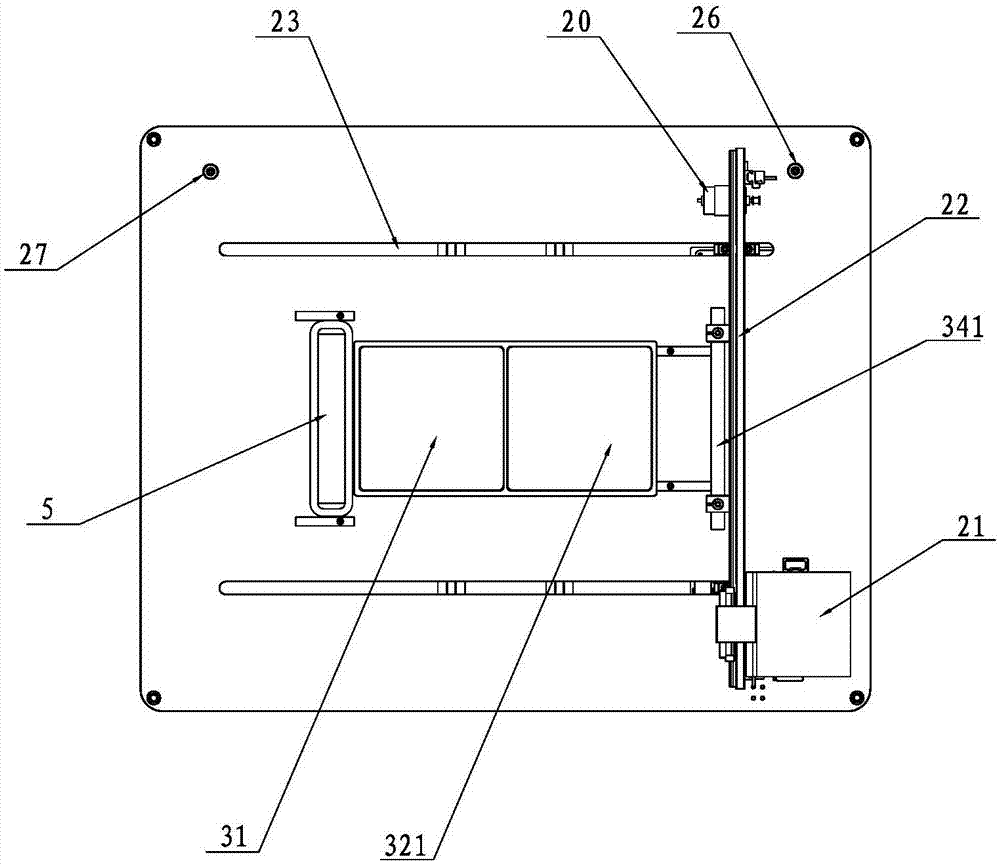

[0037] The spray head mechanism 2 includes a spray head 21 installed on the upper surface 11 of the base, and a moving shaft 22 that drives the spray head 21 to move. Both ends of the moving shaft 22 are slidably installed on the upper surface 11 of the base. The base upper surface 11 is provided with two guide grooves 23, the two ends of the moving shaft 22 are provided with slide bars 24 matched with the guide grooves 23, and a slide rail 28 is provided at the bottom of the base upper surface 11, and the moving shaft 22 is connected with the slide rail 28 through the slide block 29, and the slide block 29 is driven to move along the slide rail 28 by the moving motor 25, so that the moving sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap