Laser metal 3D printing method capable of achieving customization of local solidification structures of nickel base functional part

A 3D printing, local solidification technology, applied in the direction of additive manufacturing, improving energy efficiency, improving process efficiency, etc., can solve the problems of complex physical process and many influencing parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] The present invention specifically comprises the following steps:

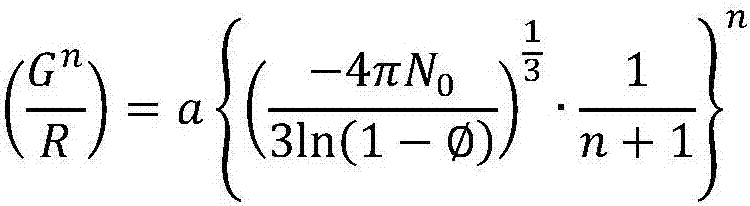

[0027] Step 1: According to the CET model formula of laser processing nickel-based alloy columnar to equiaxed dendrite transformation

[0028]

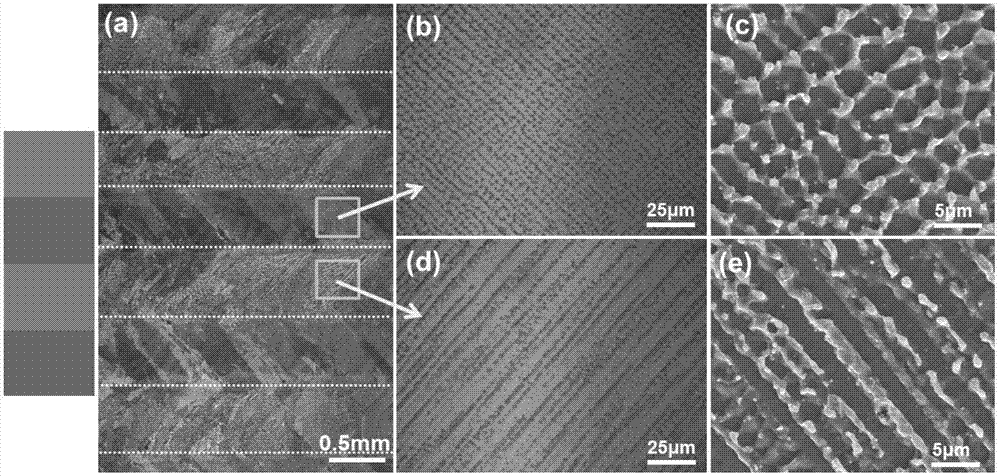

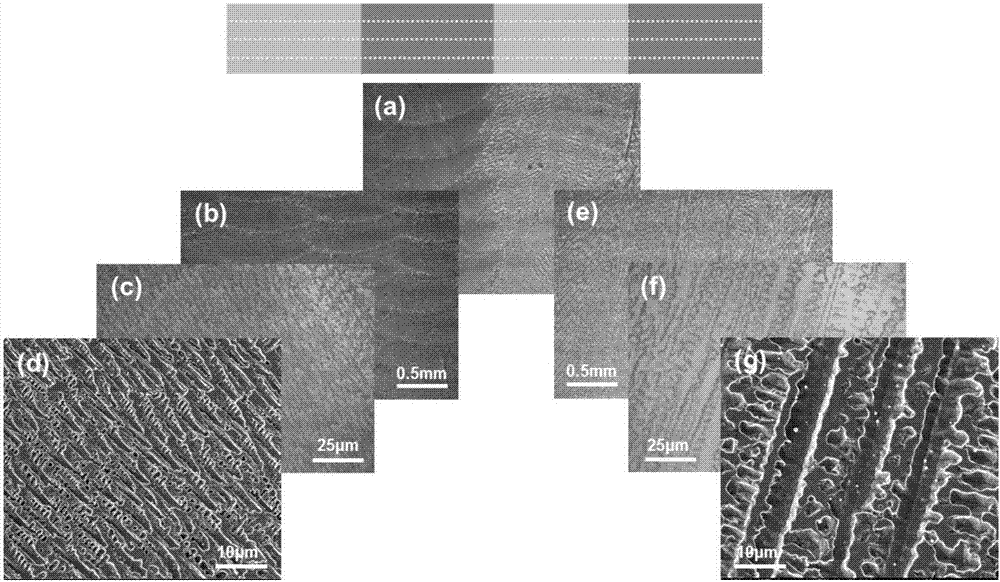

[0029] where a, n, N 0 and are the relevant parameters of nickel-based alloys, which are respectively taken as 1.25×10 6 , 3.4, 2×10 15and 0.66%, with the temperature gradient G as the ordinate and the solidification rate R as the abscissa, the critical curve of the CET transformation of the nickel-based alloy is drawn, wherein the range of the ordinate G is 10 3 -10 8 K / m, the range of abscissa R is 10 -4 -10 2 m / s, the curve divides the G-R two-dimensional coordinate system into two regions, where the upper left of the critical curve is the columnar dendrite region, and the lower right of the critical curve is the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com