Laser cutting device and method

A laser cutting and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

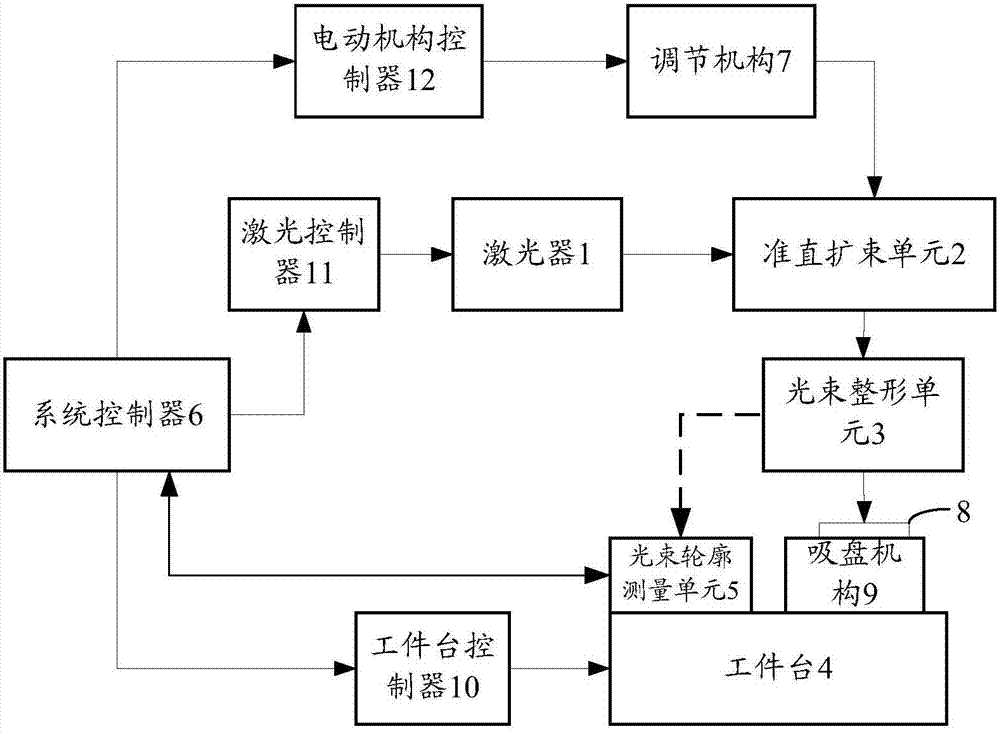

[0024] Such as figure 1 As shown, the present invention provides a laser cutting device, comprising: a laser 1, a collimator beam expander unit 2, a beam shaping unit 3 and a workpiece table 4 arranged in sequence along the optical path, and a beam profile set on the workpiece table 4 Measuring unit 5, and a system controller 6 connected to the laser 1, the collimating beam expanding unit 2, the workpiece table 4 and the beam profile measuring unit 5 respectively, and the collimating beam expanding unit 2 includes a continuously adjustable As for the mirror group, an adjustment mechanism 7 is provided between the system controller 6 and the mirror group. The workpiece table 4 is provided with a suction cup mechanism 9 to absorb the object 8 to be cut. Preferably, the detection surface of the beam profile measurement unit 5 is at the same vertical height as the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com