Seam welder for automatically welding oil storage cylinder and base of automobile damper

An automobile shock absorber and automatic welding technology, which is applied in the field of seam welding machines, can solve the problems of swing phenomenon, inability to automatically adapt to changes in workpiece diameter and seam welding wheel diameter, and unsatisfactory centering effect, so as to reduce personnel, Significant economic benefits and the effect of reducing space occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

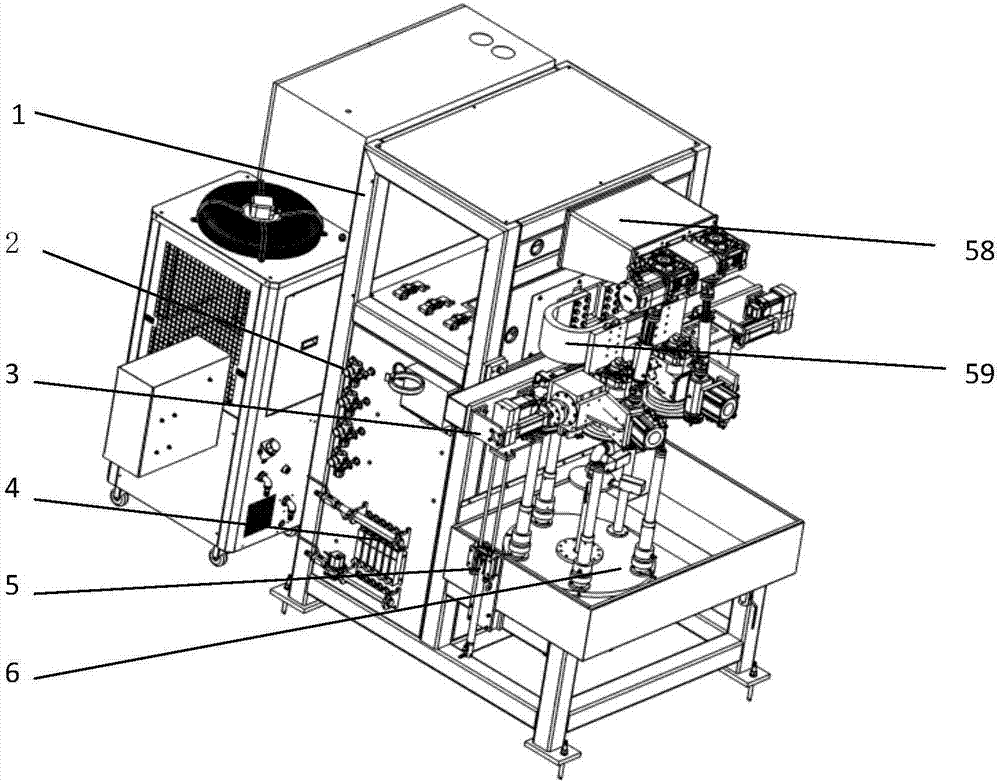

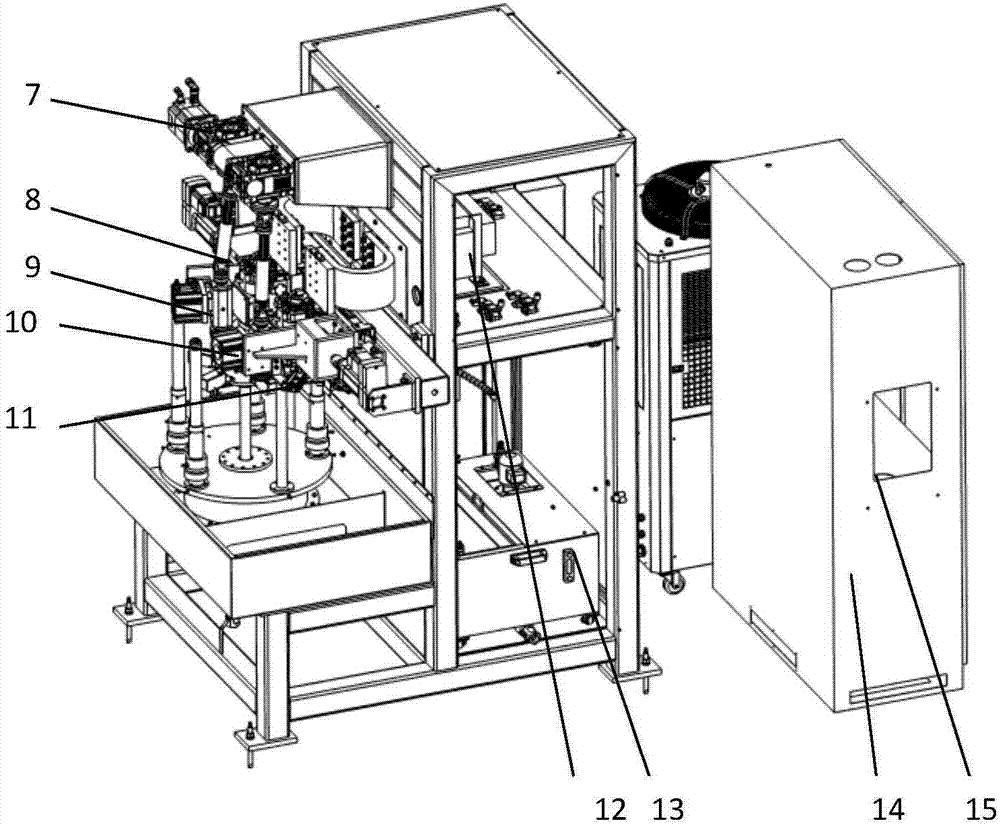

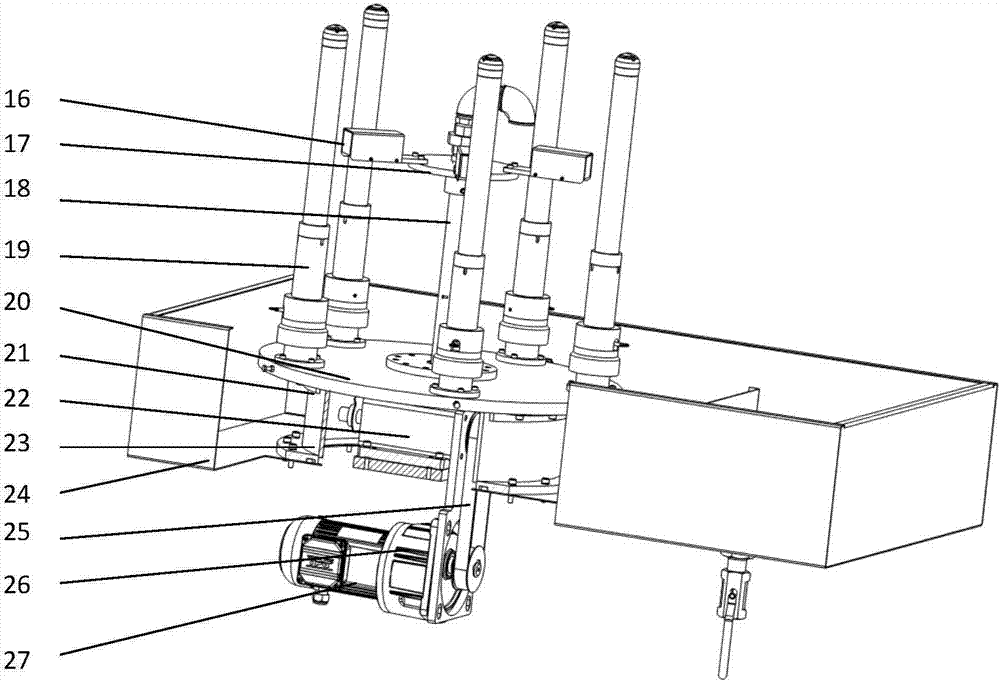

[0023] The present invention consists of a welding machine body 1, an air circuit assembly 2, a pressurizing mechanism 3, a water circuit assembly 4, a water blowing device 5, a rotary table 6, a seam welding wheel driving mechanism 7, a left driving wheel pressing assembly 9, Right driving wheel pressing mechanism 10, displacement detection mechanism 11, welding transformer 12, cooling water tank assembly 13, electric control box 14 are formed.

[0024] figure 1 , 2 It is shown that the welding machine body 1 is a tailor-welded structure of square pipe and steel plate, and the gas circuit assembly 2 and the water circuit assembly 4 are installed on the left side of the welding machine body 1 . The welding transformer 12 is installed in the inside of the welding machine body 1, and is connected to the two conductive plates of the left seam welding head assembly 45 and the right seam welding head assembly 46 through the movable conductor 59 respectively. Welding controller 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com