A kind of diamond cryogenic treatment method

A technology of cryogenic treatment and treatment method, which is applied in the field of materials science and can solve problems such as lattice dislocation and reduction of diamond performance

Active Publication Date: 2020-11-24

JILIN UNIV

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the impurities inside the diamond, as well as the crystal defects and lattice dislocations formed during the crystal growth process, the performance of the diamond will be reduced to varying degrees.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] Two kinds of artificial diamonds with different particle sizes are used, the particle sizes are 30 / 35 mesh and 35 / 40 mesh respectively. Two kinds of diamonds with different particle sizes are screened and grouped, and placed in a liquid nitrogen cryogenic box for cryogenic treatment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

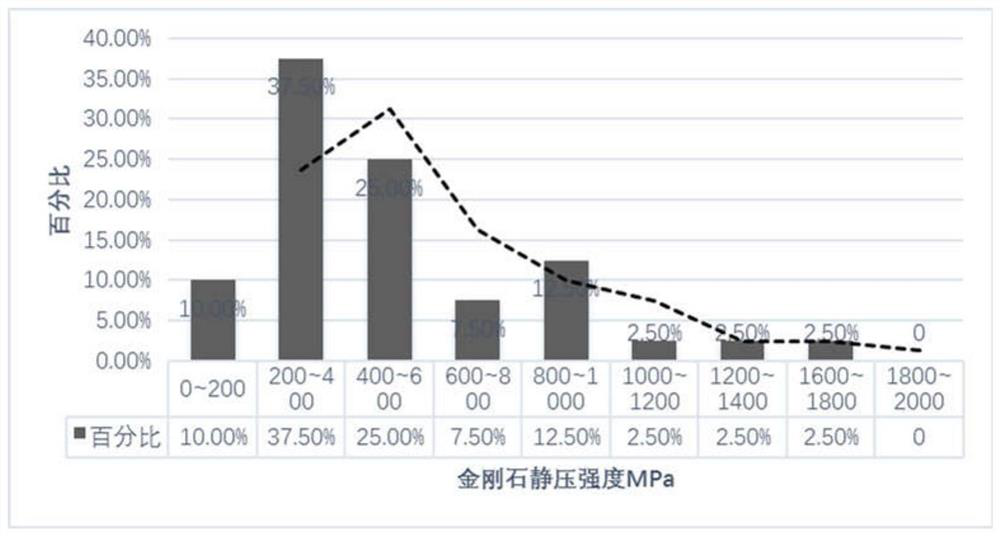

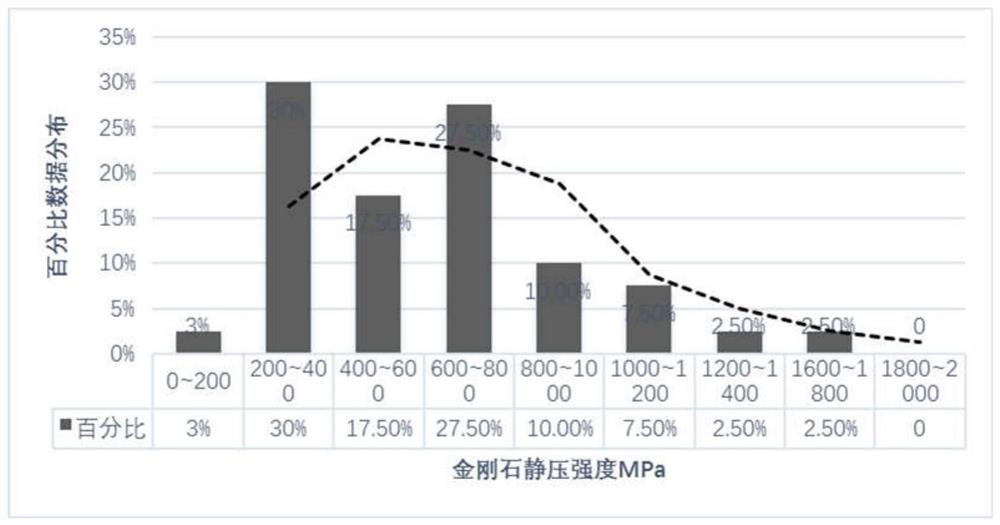

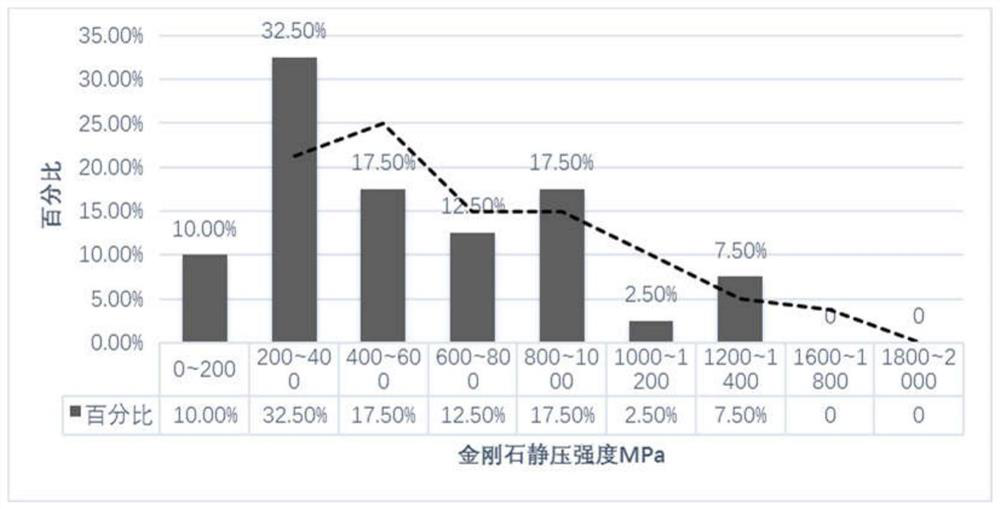

The invention discloses a cryogenic treatment method of diamond, which includes the steps of: placing 30 / 35-mesh and 35 / 40-mesh diamond in a liquid nitrogen cryogenic box to perform cryogenic treatment, wherein the temperature in the cryogenic box is stepwise reduced from room temperature, 20 DEG C, to -180 DEG C, and then is slowly increased to room temperature; then the temperature is maintainedfor a certain time and then is increased to 120 DEG C and maintained for a certain time; finally the temperature is slowly reduced to room temperature. The method can significantly increase the entire static pressure strength of two batches, 30 / 35 meshes and 35 / 40 meshes, of diamonds, wherein the number of diamond granules, of which the static pressure strength ranges from 600-800 MPa after the cryogenic treatment, is increased by about 20%. The cryogenic treatment can permanently change the crystal structure of interior of the material, solve crystal dislocation and release a part of residual stress, thereby affecting the performance of the material.

Description

technical field [0001] The invention relates to a diamond cryogenic treatment method, in particular to a method for improving performance of a diamond material through liquid nitrogen cryogenic treatment, and belongs to the field of material science. Background technique [0002] The so-called cryogenic treatment is to place the processed object (material) in a specific ultra-low temperature environment to change the microstructure and structure of the processed object (material), so as to improve the performance of the material to a certain extent. The lowest processing temperature can reach -196°C. At the beginning of the 20th century, the initial application of cryogenic technology in the aviation field was mainly in the application of liquid oxygen chemical rocket oxidizer and the use of refrigeration devices in spacecraft, as well as liquid oxygen fuel and nuclear powered rocket propellants. Later, some researchers began to try to apply cryogenic technology to the proc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B32/28

Inventor 刘宝昌曹鑫李闯张弛王海源王彧佼

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com