Dredger

A technology for dredging boats and hulls, which is applied in the field of river bed garbage cleaning equipment, and can solve the problems of failing to meet the requirements of river bed deep cleaning, limited cleaning effect, and unsatisfactory cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

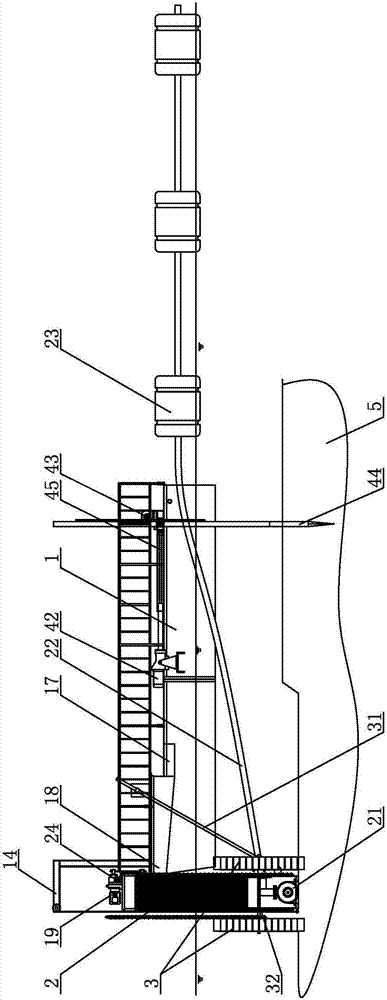

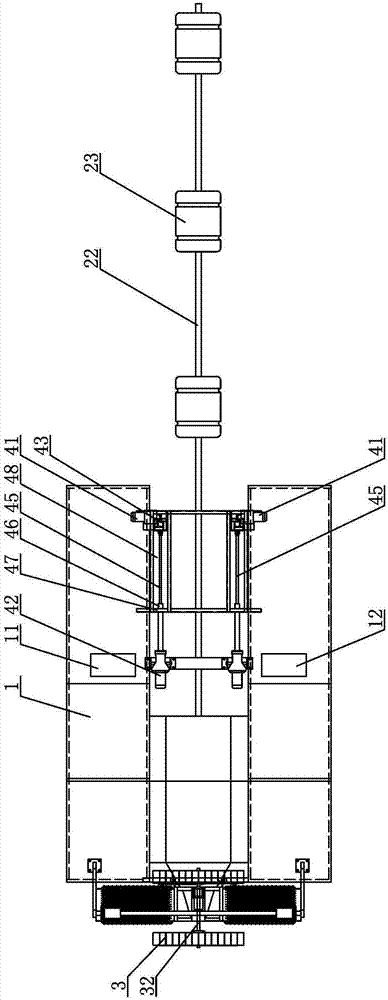

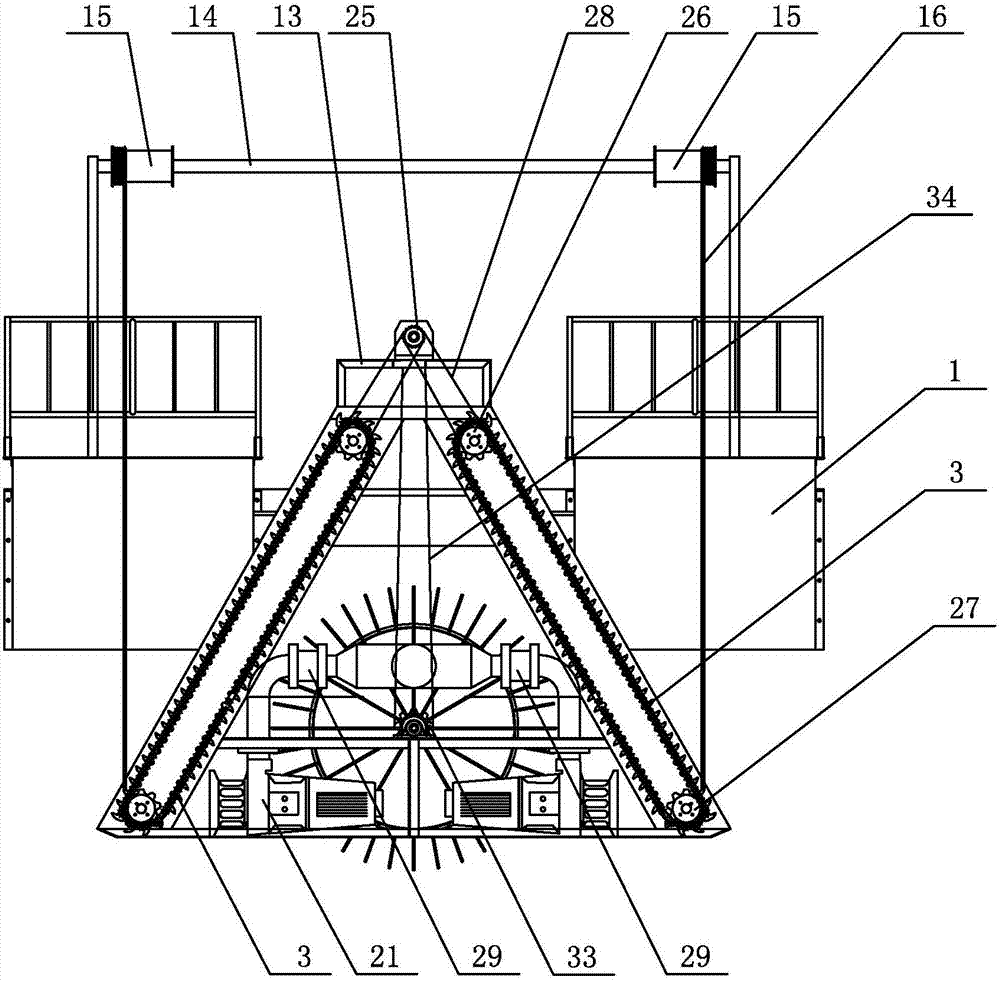

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] Examples of dredging vessels, such as Figure 1 ~ Figure 3 As shown, it includes a hull 1, a mud cleaning device, a garbage recovery device, a propulsion positioning device and a corner device. An electric control box 11 and a tool box 12 are installed on the hull 1. The mud cleaning device includes two rings of rake tooth grilles 2, two A mud suction device 21, a sludge conveying pipe 22 and a plurality of positioning floats 23. In this embodiment, the mud suction device 21 is specifically a submersible sewage pump, and the front end of the hull 1 is rotatably installed with a first bracket 13 and a second bracket 14 , the first support 13 is located below the second support 14, the top of the first support 13 is equipped with a first drive motor 24 and a first sprocket 25, the first sprocket 25 is installed at the output end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com