Self-anchoring heat-preservation decorative plate and manufacturing method and mounting method thereof

A technology for thermal insulation decorative panels and installation methods, which are applied in building construction, covering/lining, construction, etc., can solve the problems of low price advantage of thermal insulation decorative panels, high fastener strength requirements, and inorganic panels with heavy weight, etc. Light, shortened construction period, and strong overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

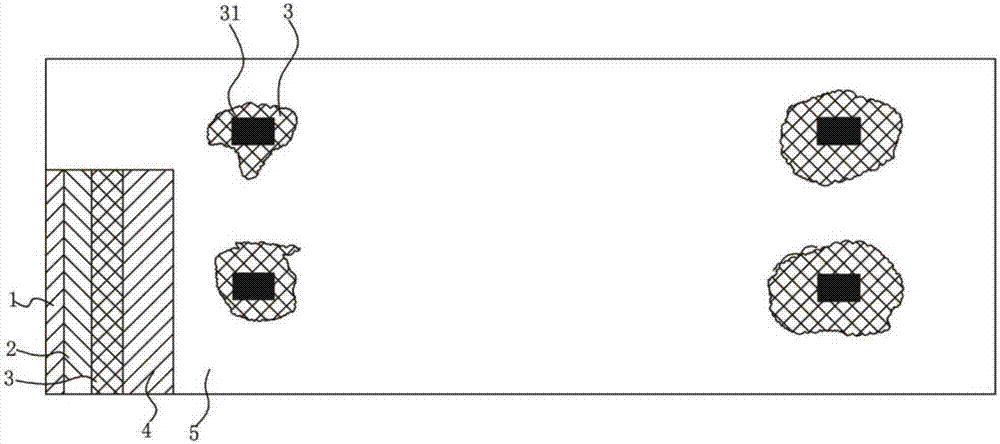

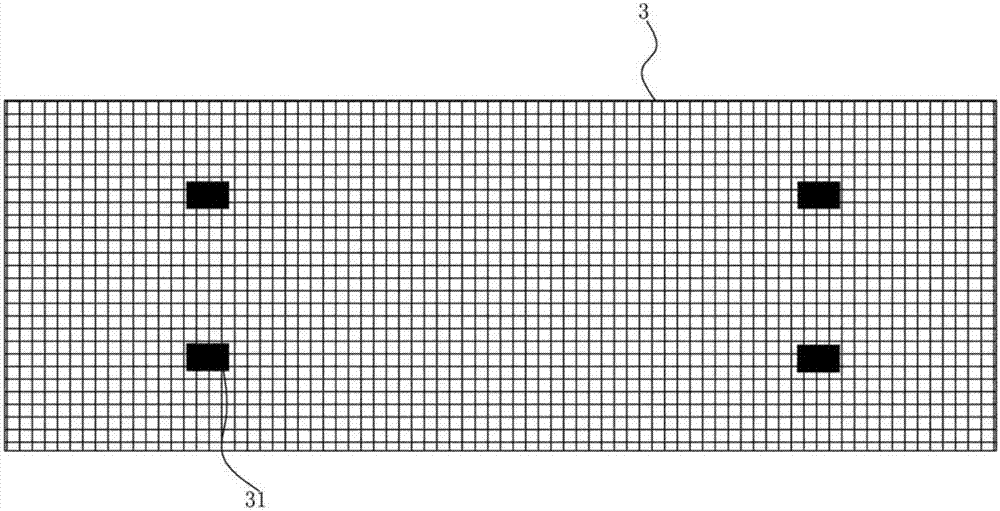

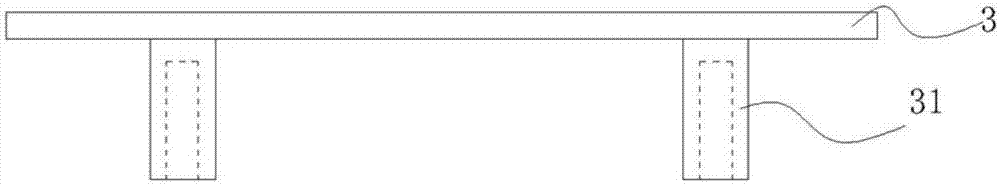

[0053] Such as figure 1 , figure 2 , image 3 As shown, a self-anchor thermal insulation decorative board, which sequentially includes a thermal insulation board 1, a low-alkalinity anti-crack mortar layer 2, a reinforcement grid 3, an anti-crack mortar layer 4 and a finish layer 5 from the inside to the outside; An anchor thread sleeve 31 is provided on the inner surface of the grid 3, and the anchor thread sleeve 31 is perpendicular to the reinforced grid 3, and the reinforced grid 3 and the anchor thread sleeve 31 are plastic integrally formed structures; The anchor threaded sleeve 31 passes through the low-alkalinity anti-cracking mortar lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com