Main engine room cover locking structure of unmanned drug spraying machine

A technology for the main cabin and spraying machine, which is applied to aircraft parts, building structures, building fastening devices, etc. It can solve the problems of increasing the difficulty of operation, loosening of the main cabin cover, and difficulty in processing and manufacturing, so as to achieve easy implementation, Easy to process and assemble, easy to process and produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

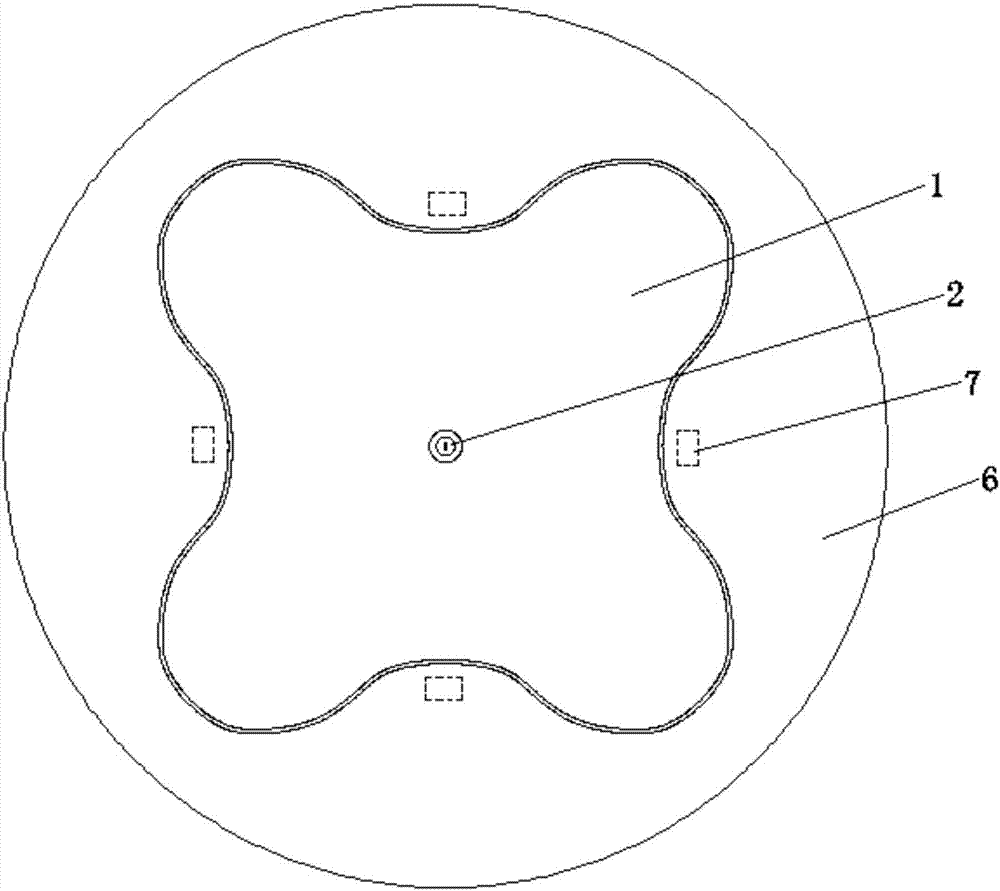

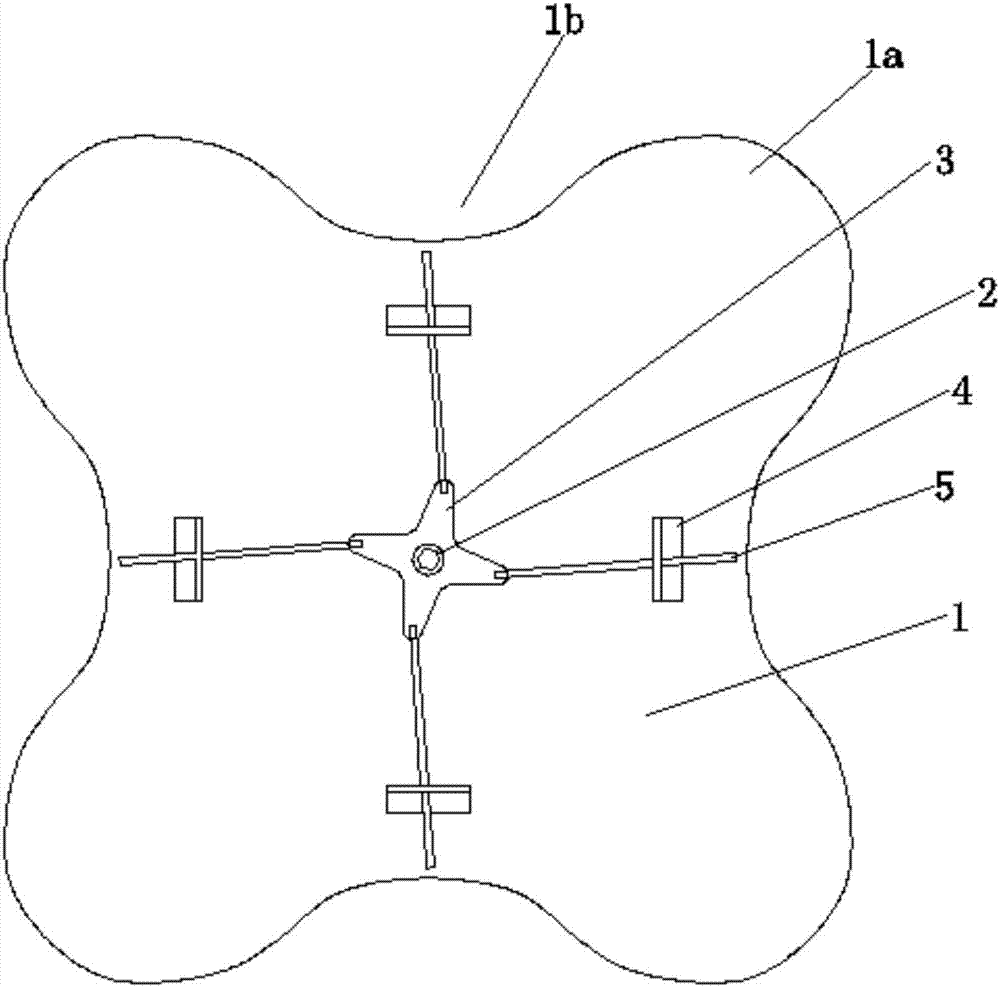

[0017] like figure 1 , figure 2 Shown, the present invention is made up of main engine compartment 6 and main engine compartment cover 1 two major parts. Wherein, the main engine compartment cover 1 is a spherical structure with a high center and a low edge. The outer edge of the main engine compartment cover 1 is integrally formed with four flanges 1a uniformly distributed on the circumference. The flanges 1a are arc-shaped, and there is a smooth transition between two adjacent flanges 1a through depressions 1b. The top of the main cabin 6 is provided with an opening, the shape and size of which are adapted to the main cabin cover 1, and the main cabin cover 1 is fastened to the opening at the top of the main cabin 6 to seal the opening. The inner space of the main engine compartment 6 is divided into upper and lower parts independent of each other by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com