How damage-resistant hydraulic cylinders work

A working method and hydraulic cylinder technology, applied in the direction of fluid pressure actuating devices, mechanical equipment, etc., can solve problems such as damage, affecting the stability of the hydraulic system, impact, etc., and achieve the effect of avoiding loopholes or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through specific implementations:

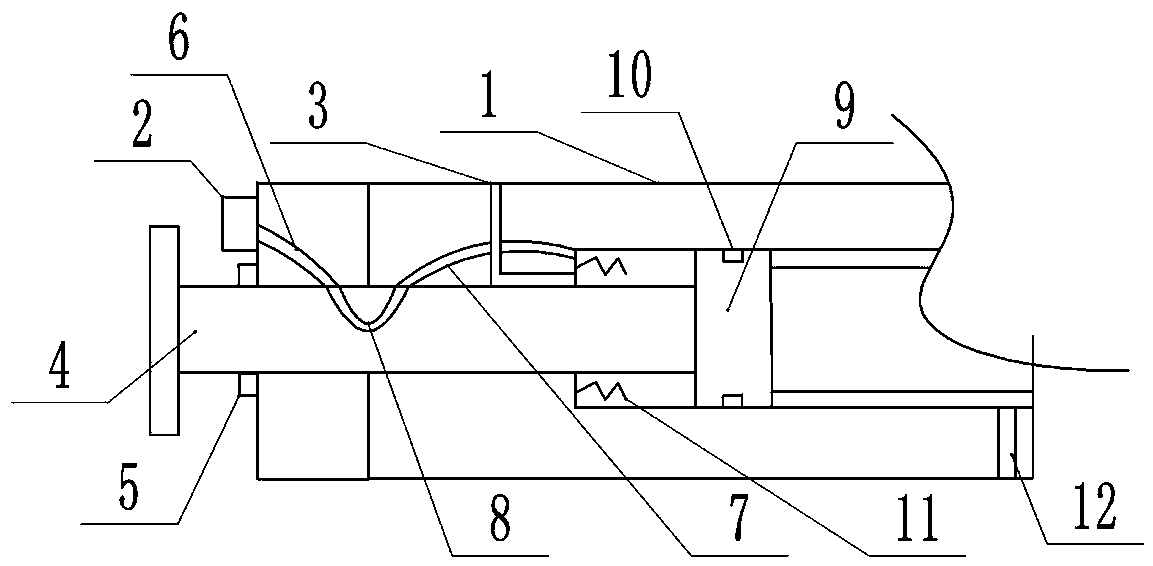

[0017] The reference signs in the drawings of the specification include: body 1, high-pressure air pump 2, first oil port 3, piston rod 4, sealing ring 5, first air pipe 6, second air pipe 7, u-shaped pipe 8, piston 9, seal Ring 10, spring 11, second oil port 12.

[0018] The embodiment is basically like figure 1 Shown:

[0019] The damage-preventing hydraulic cylinder of this embodiment includes the body 1 of the hydraulic cylinder. The body 1 has a piston 9 cavity, and the piston 9 cavity is provided with a buffer spring 11; the piston 9 cavity is slidably connected to the piston 9 and the two pistons 9 A piston 9 rod 4 is connected to the sides, a sealing ring 5 is provided at the gap where the body 1 and the piston 9 rod 4 are connected, and a sealing ring 10 is provided at the connection between the piston 9 and the body 1. The body 1 is provided with a first oil port 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com