Measurement method for base fluid density of organic salt drilling fluid or well completion fluid

A measurement method and drilling fluid technology, applied in the field of oil and gas field drilling, can solve the problems of long time, high sample volume, affecting rheological properties, etc., and achieve the effect of convenient and fast process operation, simple process operation and small sample demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

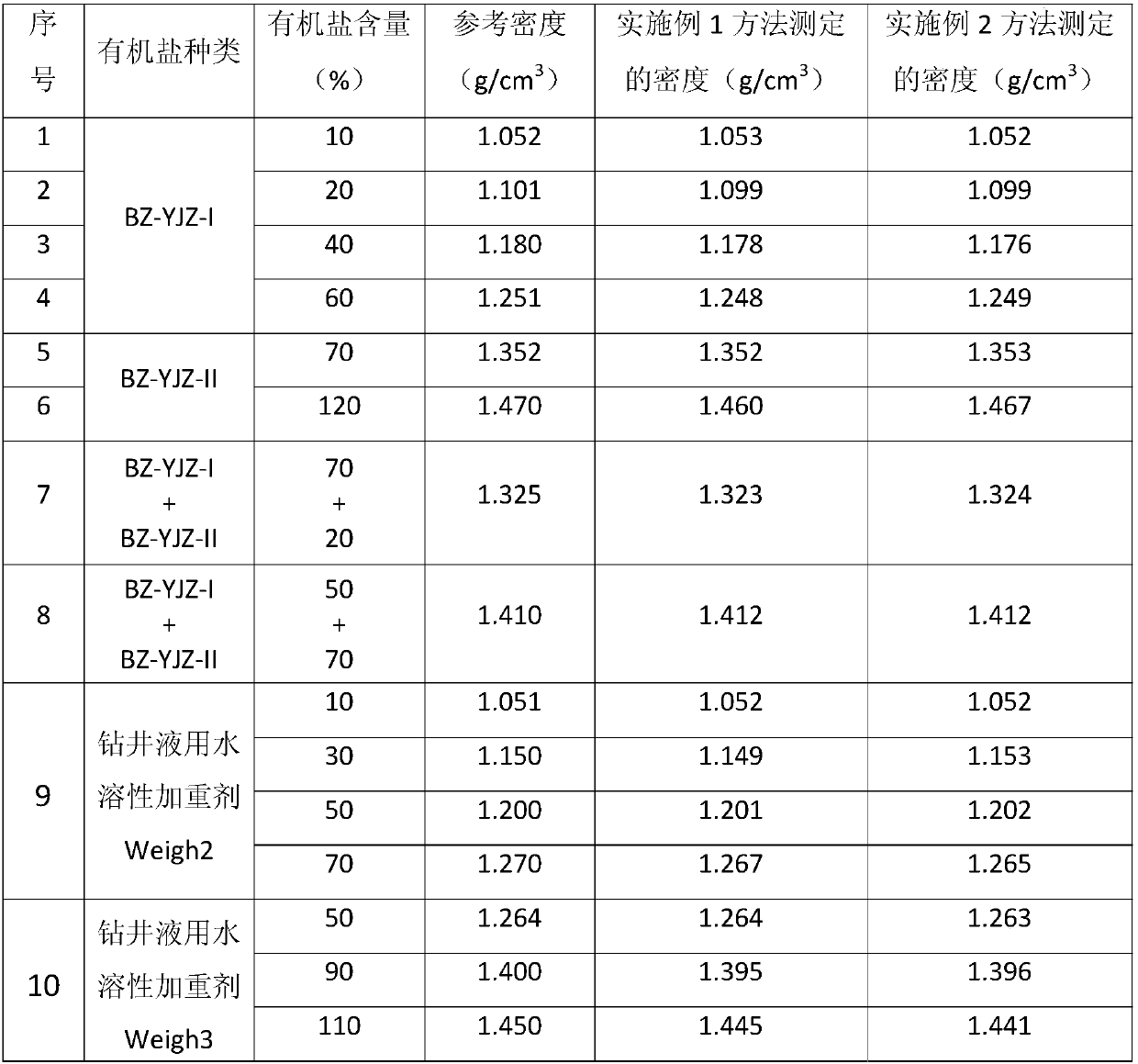

Examples

Embodiment 1

[0024] A method for measuring the density of organic salt drilling fluid or completion fluid base fluid, comprising the steps of:

[0025] (1) Preparation of base fluid: filter the organic salt drilling fluid with a medium-pressure filter loss meter, and the obtained filtrate is the organic salt drilling fluid or completion fluid base fluid;

[0026] (2) The organic salt drilling fluid or completion fluid base fluid prepared by using a micro-injector is used, and the micro-injector is used to rinse once before drawing the sample. The method of rinsing is to rinse twice with distilled water first, Exhaust the air bubbles in the needle tip to avoid the difficulty of pulling the core when drawing samples and affect the accuracy of analysis and capacity accuracy, then rinse with organic salt drilling fluid or completion fluid base fluid once, and then absorb organic salt drilling fluid or completion fluid Base liquid, record the volume V1 in the micro-injector, and measure the mas...

Embodiment 2

[0032] A method for measuring the density of organic salt drilling fluid or completion fluid base fluid, comprising the steps of:

[0033] (1) Preparation of base fluid: filter the organic salt drilling fluid with a medium-pressure filter loss instrument, and the obtained filtrate is the organic salt drilling fluid.

[0034] Well fluid or completion fluid base fluid;

[0035] (2) Rinse the micro-injector once before drawing the sample. The method of rinsing is to rinse with distilled water for 3 times to exhaust the air bubbles in the needle tip, so as to avoid the difficulty of pulling the core when drawing the sample and affect the accuracy of the analysis. and capacity accuracy, rinse once with organic salt drilling fluid or completion fluid base fluid, and measure the mass m3 of the micro-injector;

[0036] (3) Use the micro-sampler to absorb the organic salt drilling fluid or completion fluid base fluid, wipe off the sample adhering to the needle of the micro-sampler wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com