Trolley omni-directional movement control system and method

An omnidirectional mobile and control system technology, applied in the field of vehicle testing, can solve the problem of program inability to transplant control accuracy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

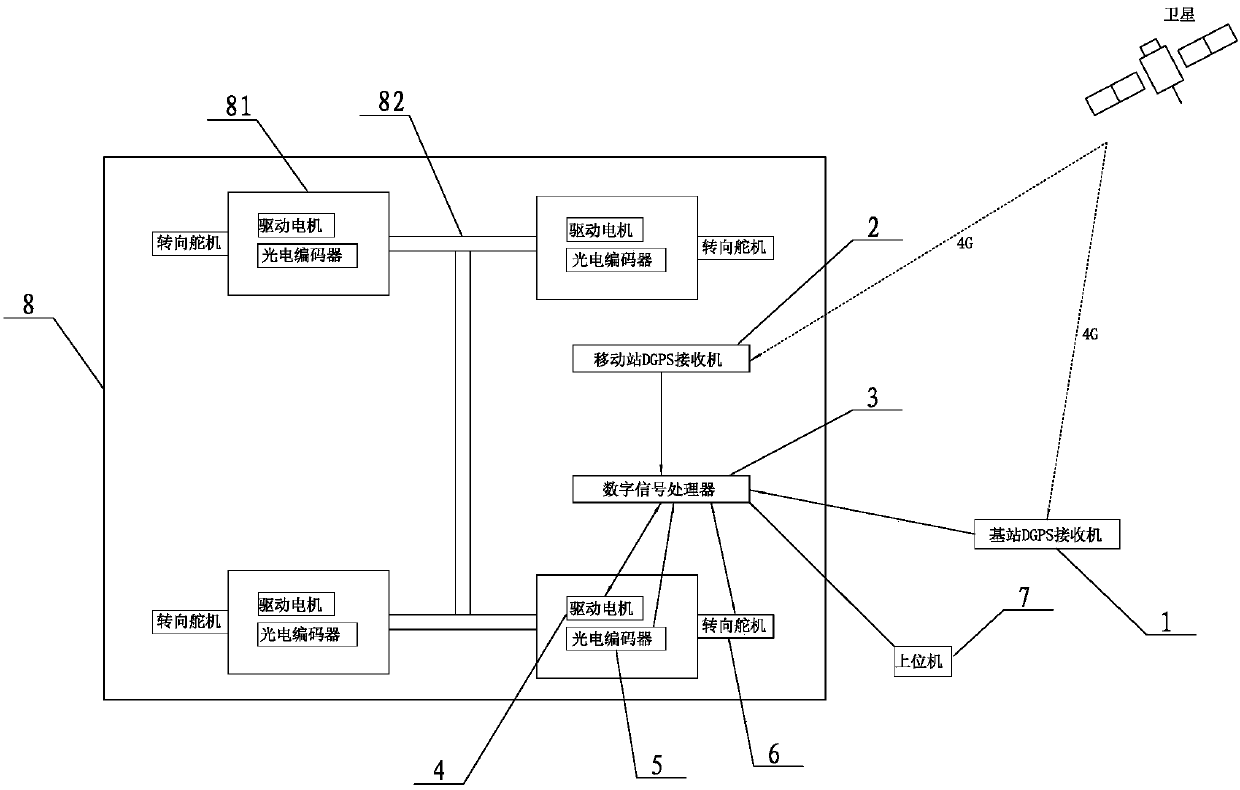

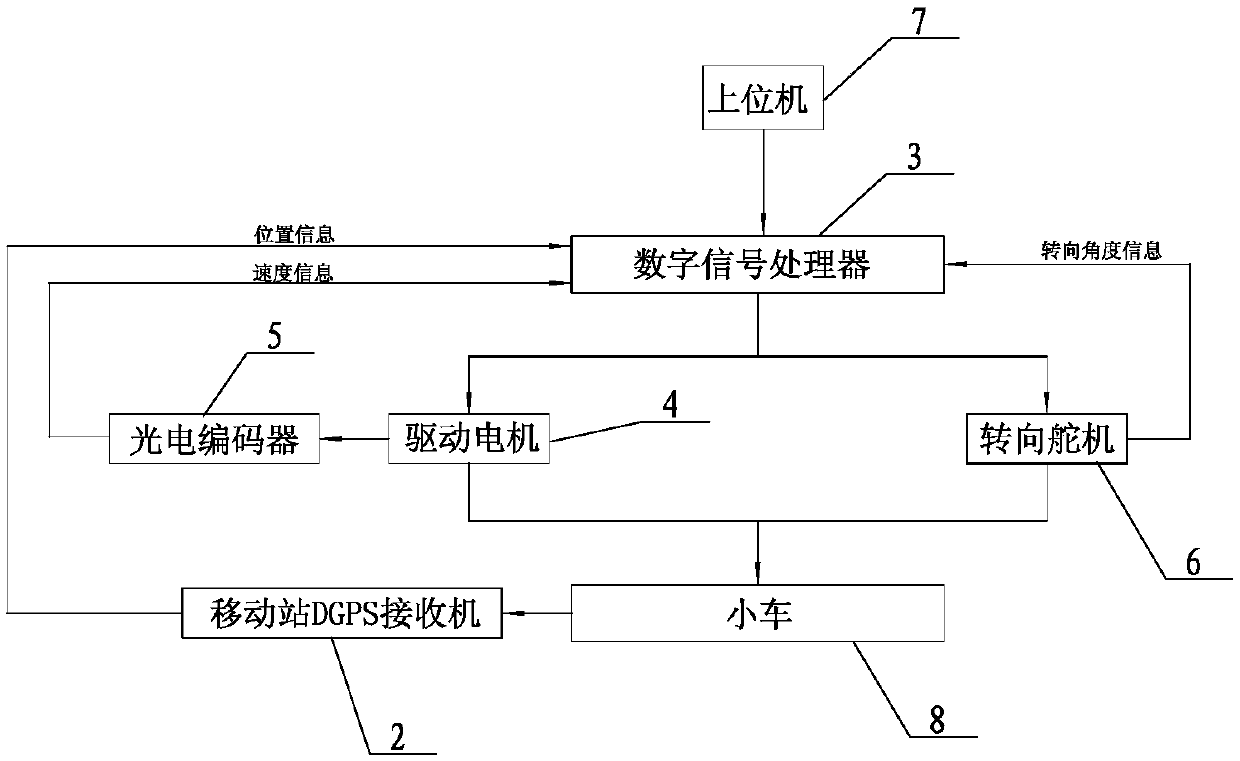

[0045] Such as Figure 1-2 As shown, the omnidirectional mobile control system of the trolley includes a base station DGPS receiver 1, a mobile station DGPS receiver 2, a digital signal processor 3, a drive motor 4, a photoelectric encoder 5 and a steering gear 6. Wherein, the base station DGPS receiver 1, as a fixed base station, is placed somewhere in the test site, and sends data to the digital signal processor 3 through an external connection to a wireless transmission module. The digital signal processor 3 is respectively connected with the mobile station DGPS receiver 2, the drive motor 4, the photoelectric encoder 5, and the steering gear 6 through signal lines. The mobile station DGPS receiver 2 is installed on the dolly 8, and the drive motor 4 and the photoelectric encoder 5 are installed in the dolly wheel 81 for driving the dolly wheel and measuring the wheel speed. The steering gear 6 passes through the connecting piece It is connected with the wheel 81 and is us...

Embodiment 2

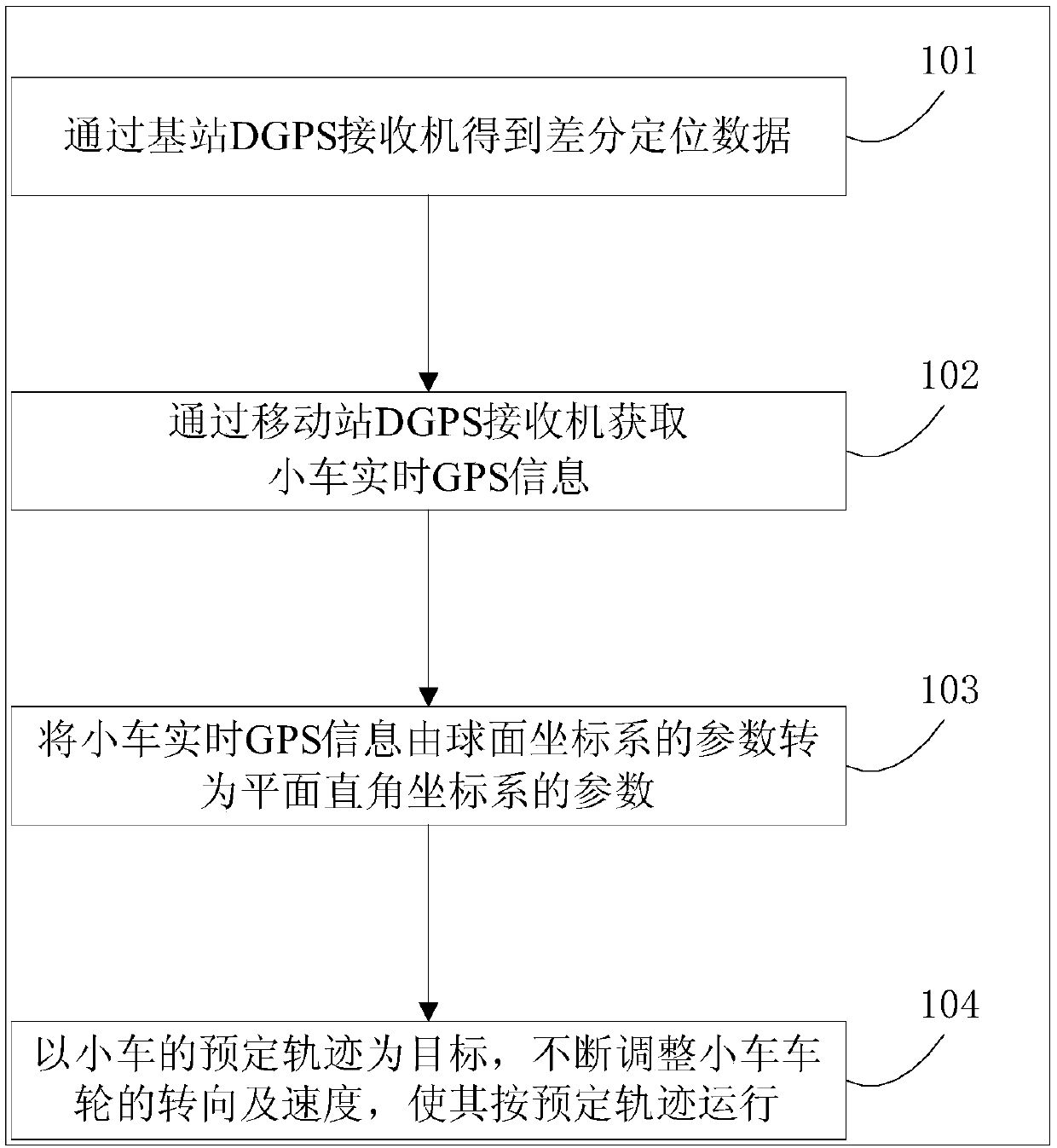

[0054] A method for controlling the omnidirectional movement of the trolley based on the omnidirectional movement control system of the trolley, such as image 3 shown, including the following steps:

[0055] 101. Accurate position information is obtained by taking the average value of multiple measurements by the base station DGPS receiver 1, and the precise position information is sent to the digital signal processor 3 for storage through an external connection to the wireless transmission module; the base station DGPS receiver 1 simultaneously Receive the satellite signal through the GPS antenna, obtain the real-time position information and send it to the digital signal processor 3, in the digital signal processor 3, obtain the differential positioning data by comparing with the above-mentioned precise position information;

[0056] 102. The DGPS receiver 2 of the mobile station, as the communication module of the vehicle terminal, receives satellite signals through the GP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com