System and method for automatically testing electrical cabinet of control system

An automatic test and control system technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of inability to detect the logical relationship of electrical cabinets, large development workload, poor scalability, etc., to enhance flexibility and reduce difficulty. and cost, the effect of saving hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

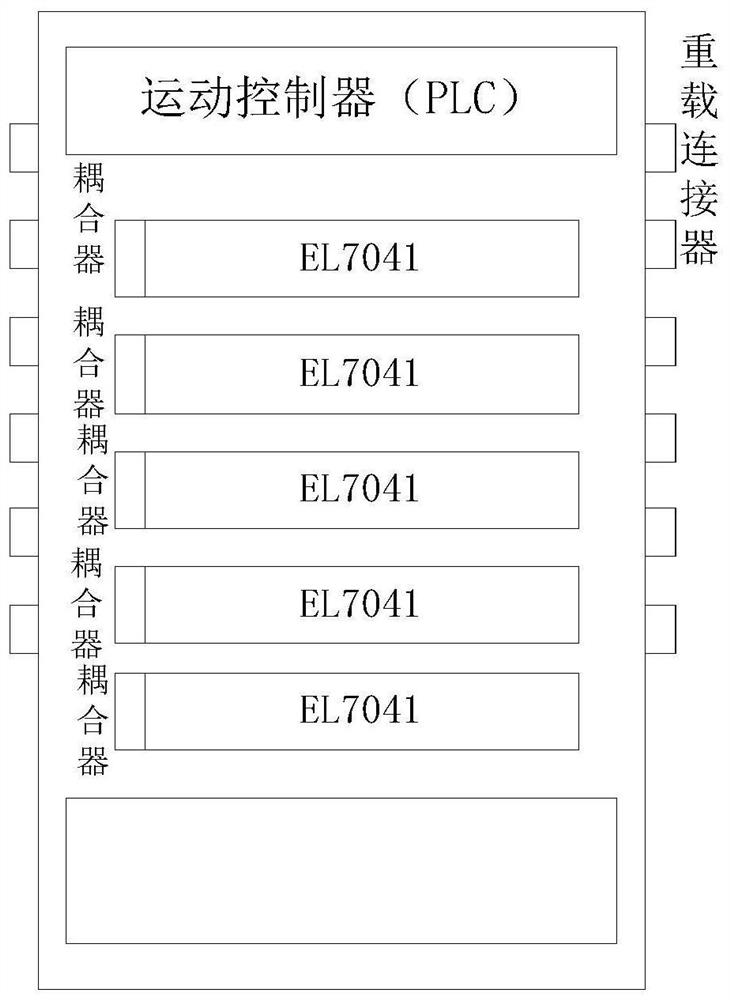

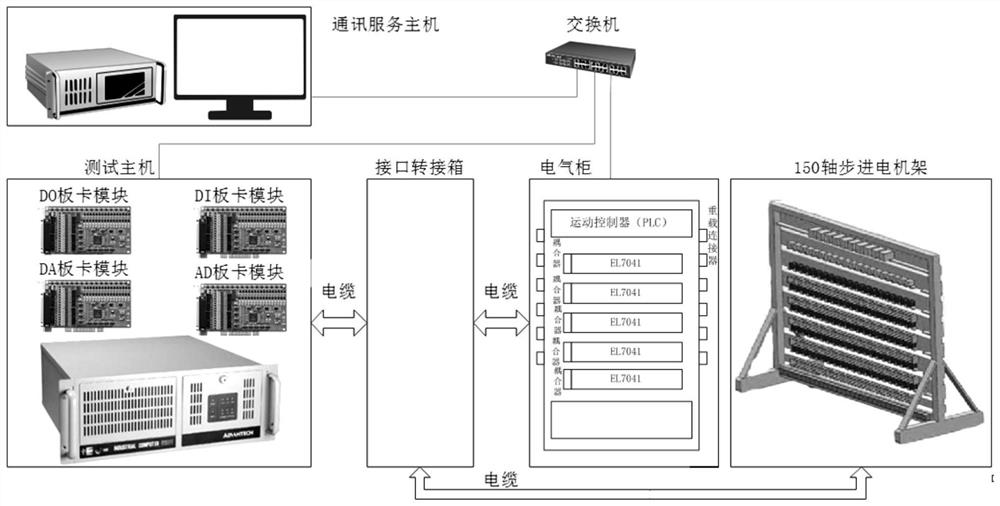

[0059] The present invention is aimed at the following scenario. A large-scale experimental device contains a large number of optical mirror frames driven by stepping motors, including one-dimensional translation mirror frames, two-dimensional adjustment mirror frames, and one-dimensional rotating mirror frames. Each mirror frame contains stepping motors, several limit switches, photoelectric switches, cylinders and other electrical components. Due to the large number of frames and the scattered areas, such as figure 1 As shown, the mirror frame control system adopts the EtherCAT bus motion control system, and the motor drive adopts the E-Bus backplane bus type drive module. Such as figure 2 As shown, the components of the control system are installed in the electrical cabinet, and are connected to external devices (stepper motors, limit switches, photoelectric switches, cylinders, etc.) through several wiring definitions on the cabinet. Realize the drive control of more th...

Embodiment 2

[0093] Such as Figure 1 to Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment provides a method for automatic testing of the electrical cabinet of the control system, and the method is applied to the electrical cabinet for the control system described in Embodiment 1. A system for automated testing, the method comprising:

[0094] Connect each module of the described system for the automatic test of the electrical cabinet of the control system;

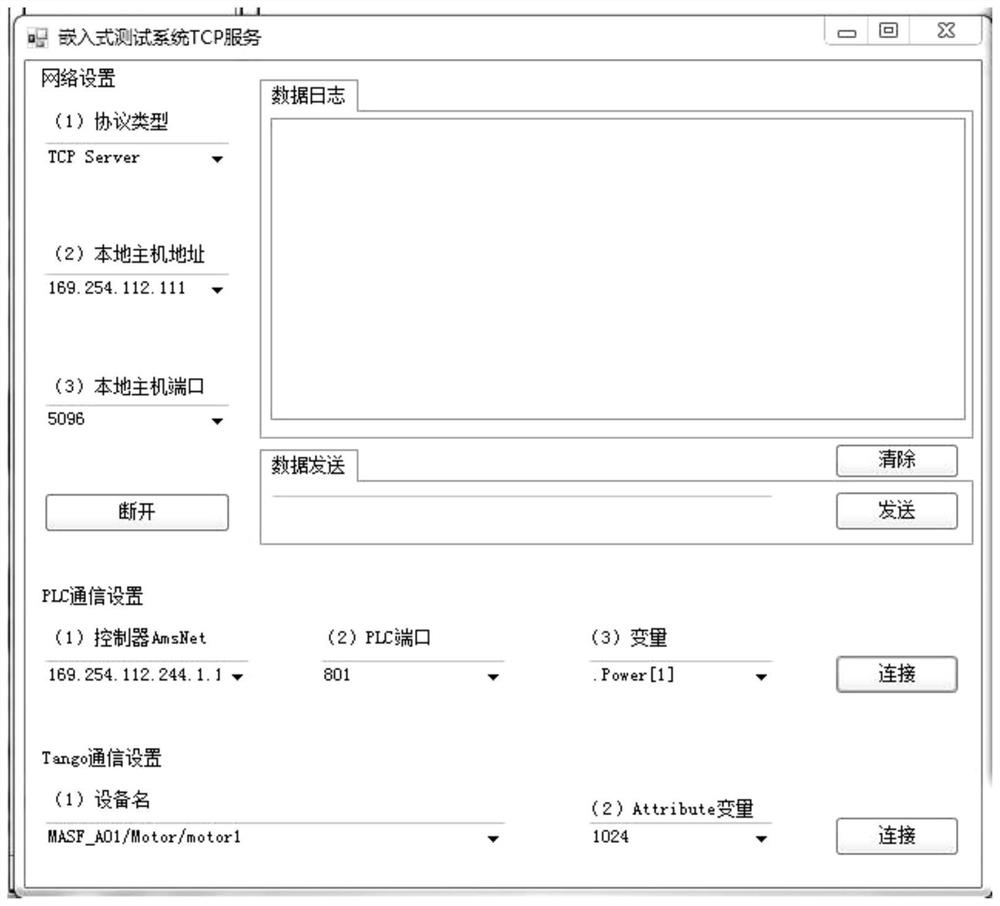

[0095] Establish the simulation model and connection relationship of each object in the test system on the ETest test software, associate each object model with the real object, configure communication parameters, physical parameters, etc.;

[0096] The test script is written in Python language to execute the automatic test process. The ETest test software controls the test host to send a DO signal to the electrical cabinet. The controller PLC receives the signal and feeds back to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com